Ship and ship side cabin ventilation method

A ventilation method and technology for ships, which are applied in the directions of hull ventilation/heating/cooling, ship construction, and ship parts, etc., can solve the problems of reduced anti-overturning performance of ships and blockage of gas flow in ventilation pipes, so as to improve the anti-overturning ability and avoid The effect of fire spread and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

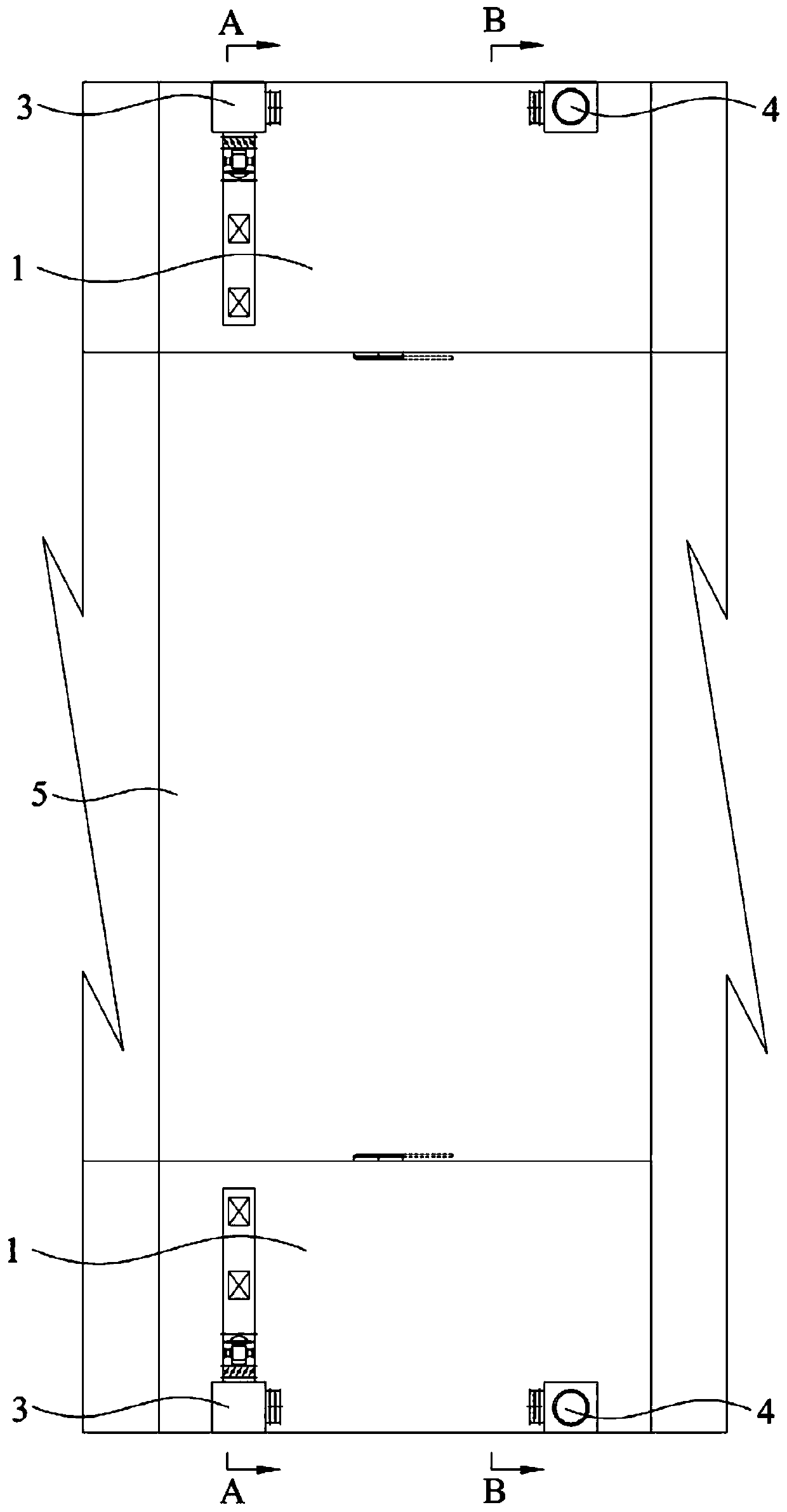

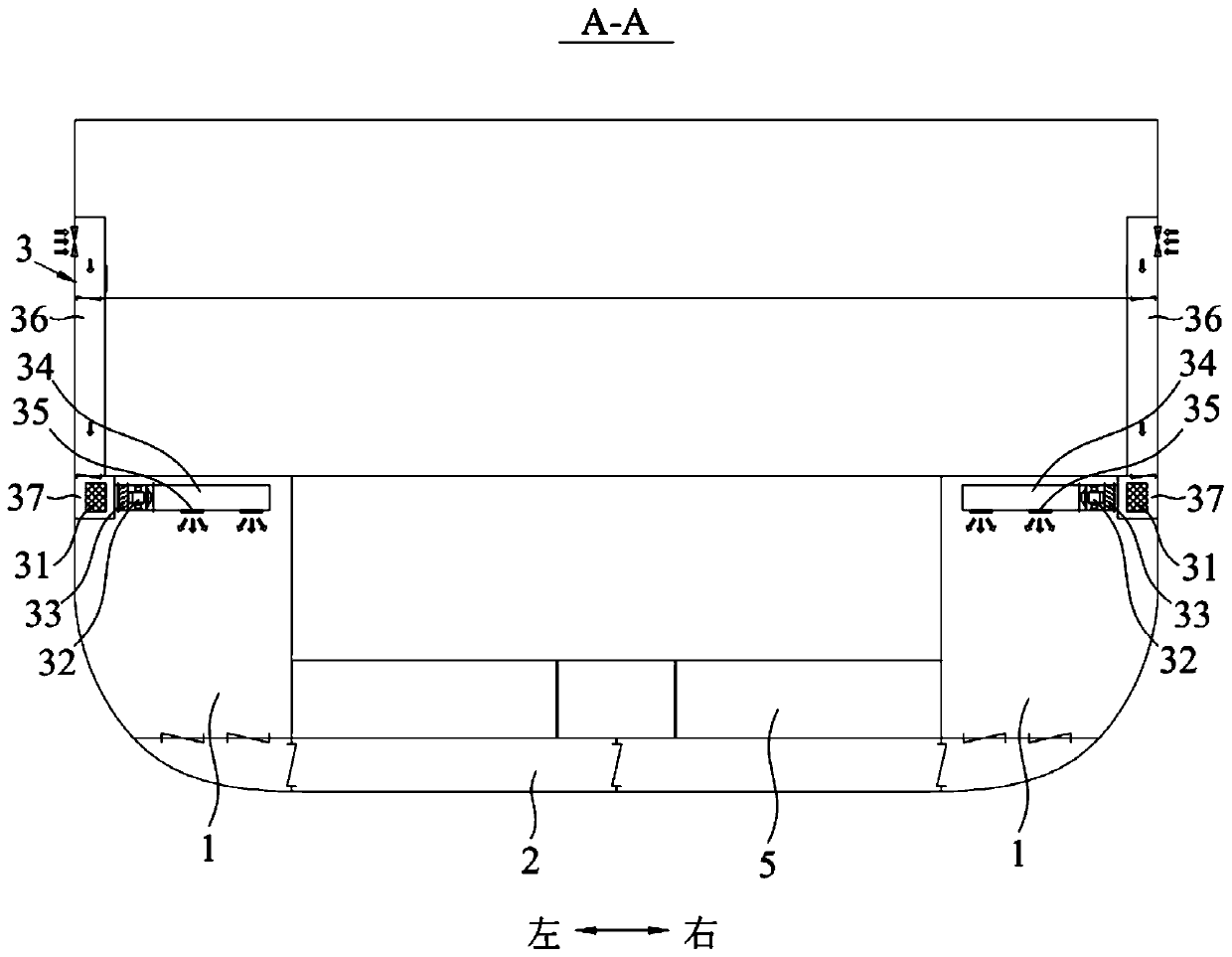

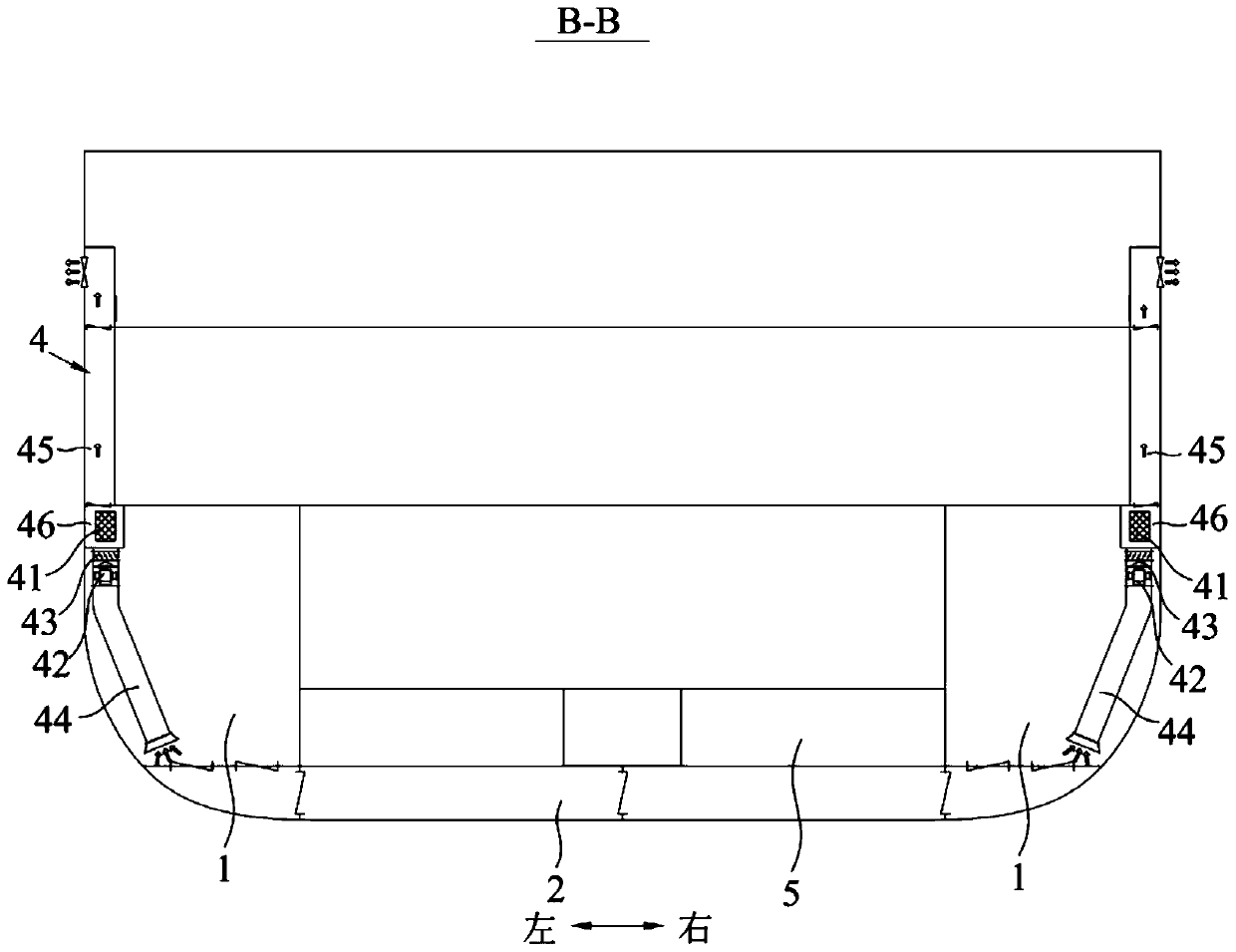

[0048] Such as Figure 1-3 As shown, this embodiment proposes a ship, which includes side tanks 1 arranged on the left and right sides of the ship. The space between the two and the upper part of the water inlet channel 2 is the midship equipment room 5 . The side tanks 1 on the left and right sides of the ship are respectively provided with a ventilation device for ventilation. The two ventilation devices have the same structure. Among them, such as figure 2 As shown, one end of the air inlet pipeline 3 is connected to the outside of the ship, the other end of the air inlet pipeline 3 is provided with a natural air outlet, and the natural air outlet is provided with a natural air outlet gate 31; the air inlet pipeline 3 is connected to one end of the outside of the ship It communicates with the natural air outlet to form a natural air inlet; the end of the air inlet pipeline 3 that is not connected to the outside of the ship is also provided with a forced air inlet; The t...

Embodiment 2

[0061] Such as Figure 4-6As shown, the present embodiment proposes a kind of ship, and its structure is exactly the same as the structure of the ship proposed in the first embodiment, the difference is only in the progress of the ventilating device of the side tanks 1 on the left and right sides of the ship proposed in the present embodiment. The air outlet of air duct 3 has only natural air outlet, and forced air intake fan 32 and supporting forced air intake gate 33, air supply pipe 34 and air supply air grid 35 are no longer set. However, the sum of the flow areas of the natural air inlet and the natural air outlet of the ventilation device in any side tank 1 of the present embodiment is not less than 10% of the cross-sectional area of the water inlet passage, so it can also It is guaranteed to improve the anti-overturning ability of the ship under the premise of meeting the requirements of forced ventilation and fire closure ventilation.

[0062] Correspondingly, based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com