A press-shear separation type variable stiffness rubber bearing and its manufacturing method

A rubber bearing and variable stiffness technology, applied in protective buildings/shelters, building types, buildings, etc., can solve the problems of poor controllability of stiffness, weak energy dissipation capacity, and small elastic range, and achieve the realization of compression shearing. Separation, enhanced energy dissipation capacity, reduced effect of superstructure reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

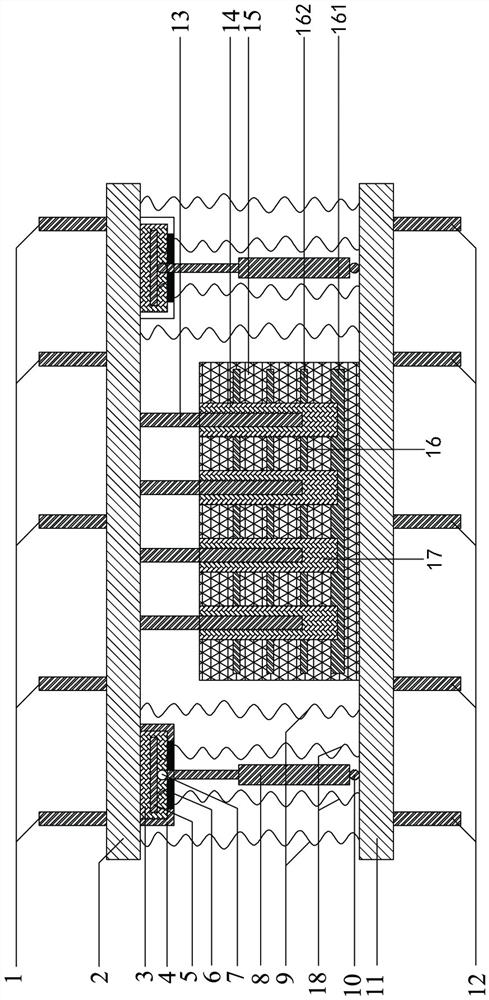

[0039] Examples see Figure 1-2 As shown, a compression-shear separation type variable stiffness rubber bearing includes a bearing upper plate 1, a bearing lower plate 11 and a shock-isolation assembly arranged between the two, and the upper side of the bearing upper plate 1 is fixed The support upper connecting piece 1 is connected, and the lower side of the support lower plate 11 is fixedly connected with the support lower connecting piece 12 .

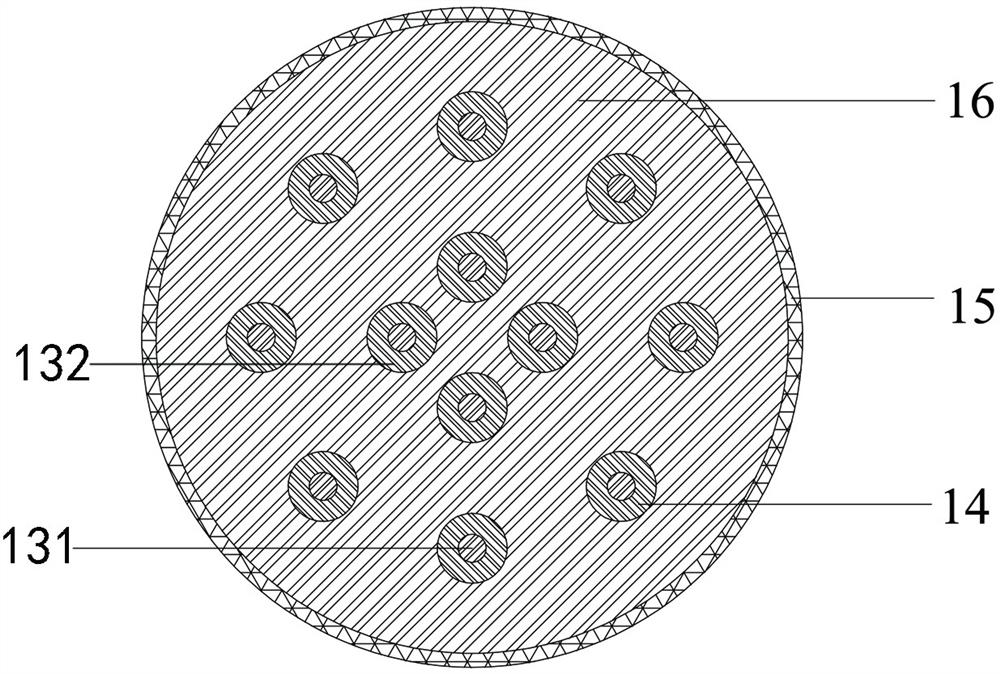

[0040] The shock-isolating assembly includes a vertical shock-isolating assembly at the side and a horizontal shock-isolating assembly at the center.

[0041] The vertical vibration isolation assembly is provided with a circle along the edge, and each vertical vibration isolation assembly includes a long vertical spring 9, a short vertical spring 17, a damper 8, a limit stop groove 4 and a limit baffle, so The limit stop groove 4 is fixedly connected to the lower side of the upper plate 1 of the support, the notch of the limit stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com