Gravity expanding constant-pressure loading coal rock creep test device and method

A creep test and gravity loading technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve problems such as unsatisfactory, large errors of gratings and pressure sensors, and large limitations, so as to avoid leakage or Effects of volatilization, saving test cost and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this specification, the principles of the present invention will be described through examples. Other aspects, features and advantages of the present invention will become clear through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

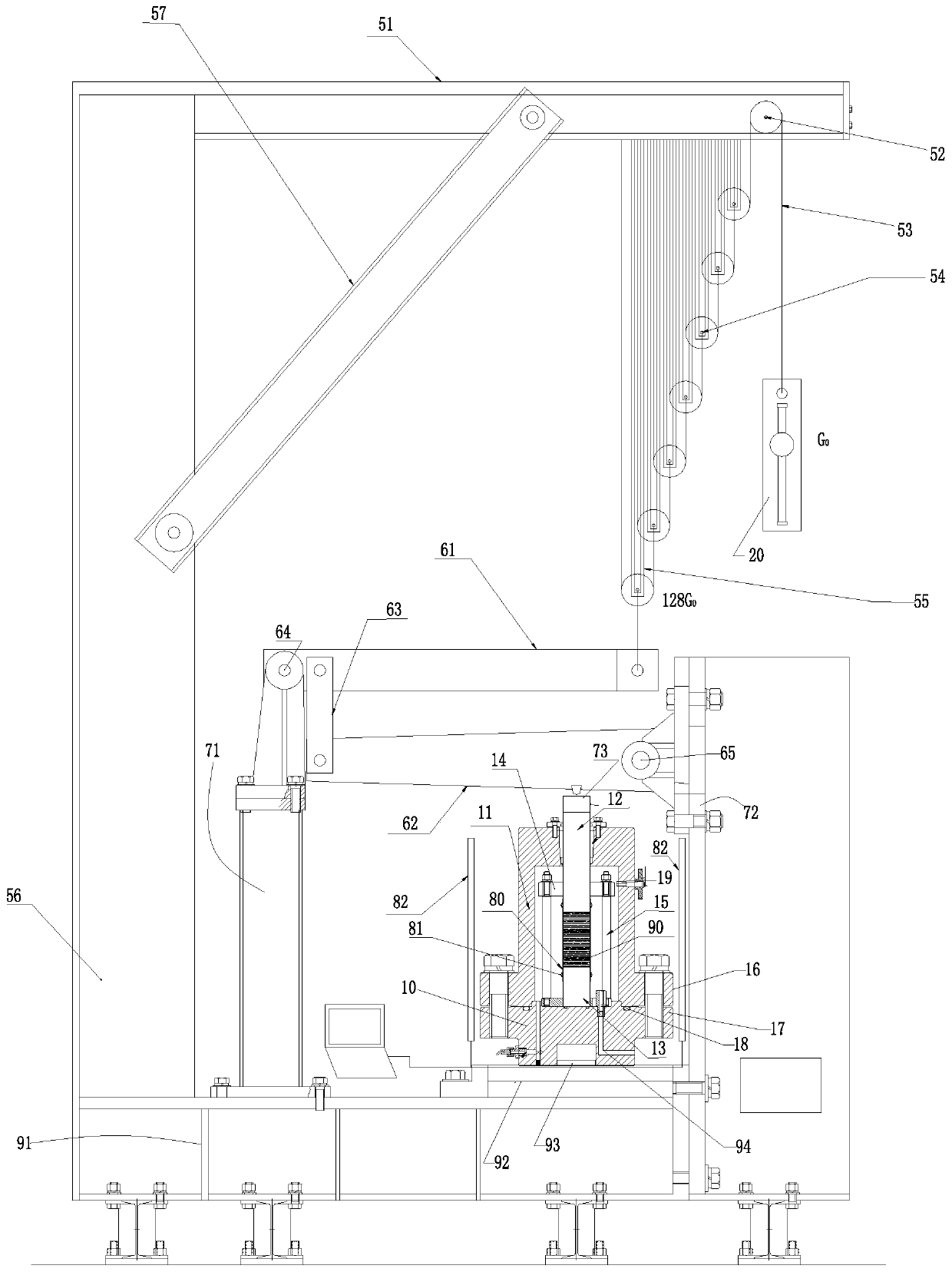

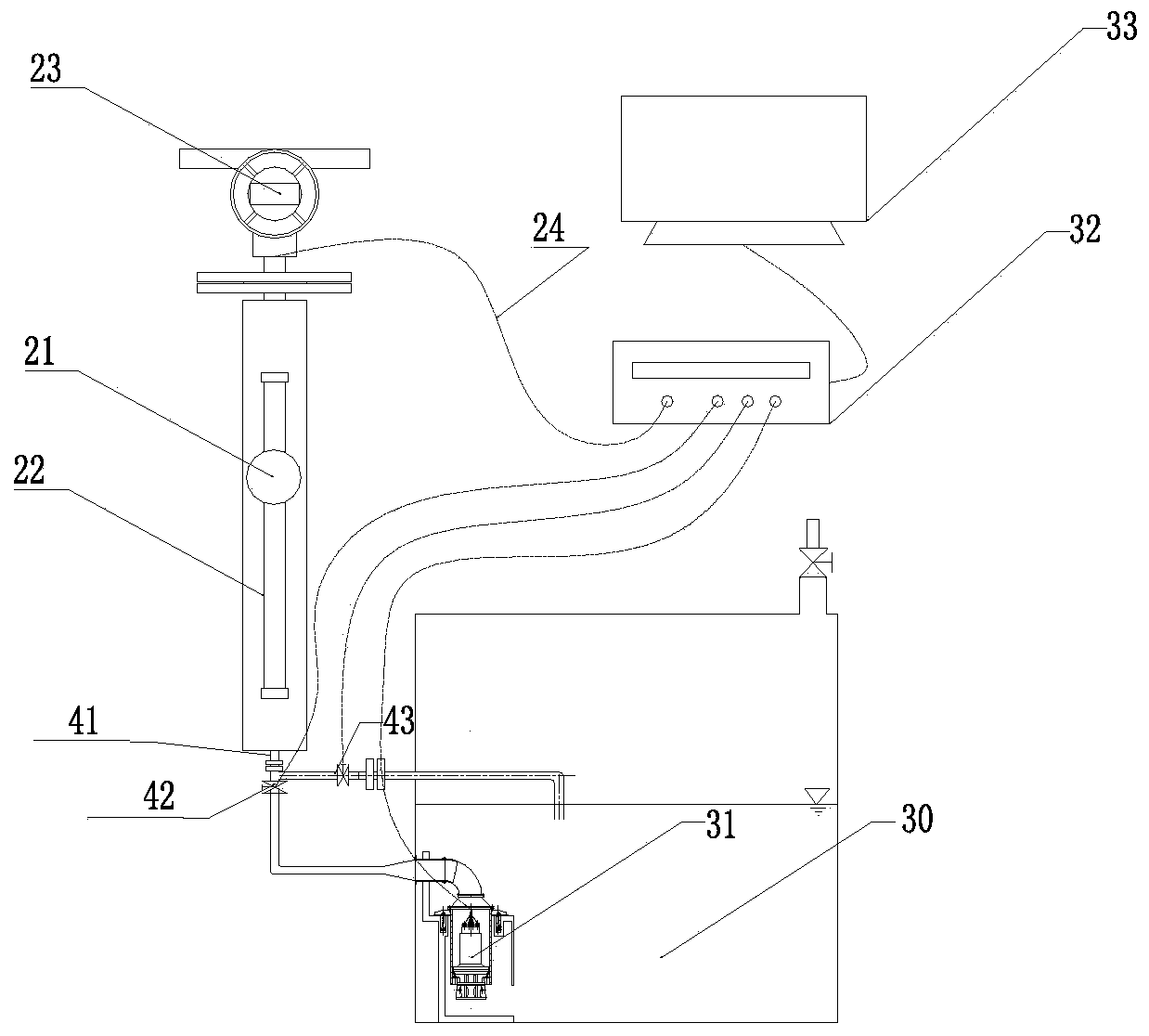

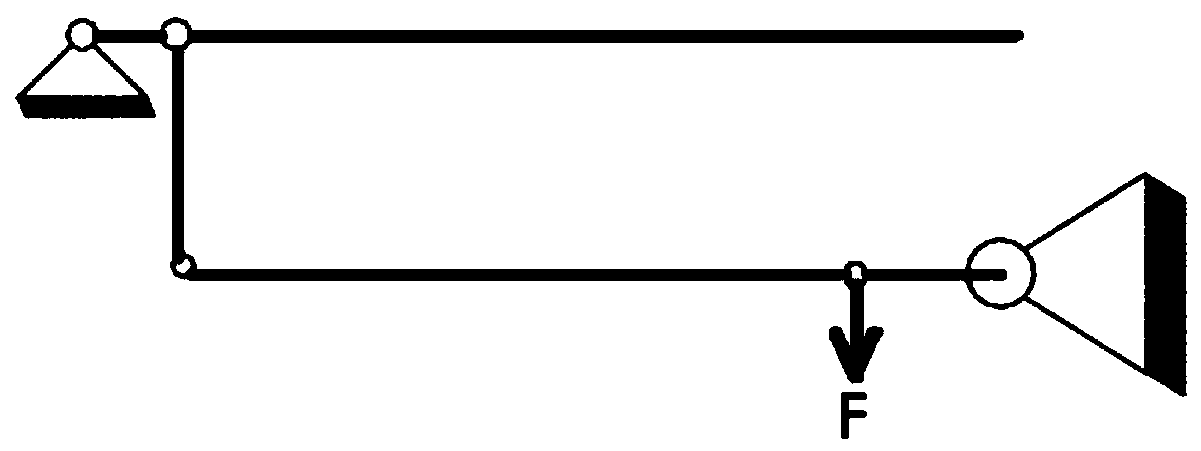

[0047] Such as Figure 1 to Figure 4 As shown, the present invention has designed a gravity expansion force constant pressure coal rock creep test device, and for studying the creep properties of coal rock under complex stress states, the principle of lever expansion force and movable pulley reverse expansion force is flexibly used to expand the force To a certain size, the triaxial pressure chamber is superimposed on the coal rock to provide stable test conditions, and in this stable environmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com