Continuous rotation torque wrench

A technology of torque wrench and torque multiplier, applied in the field of torque wrench, which can solve problems such as vibration noise, frequent maintenance, and slow rotation of fasteners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

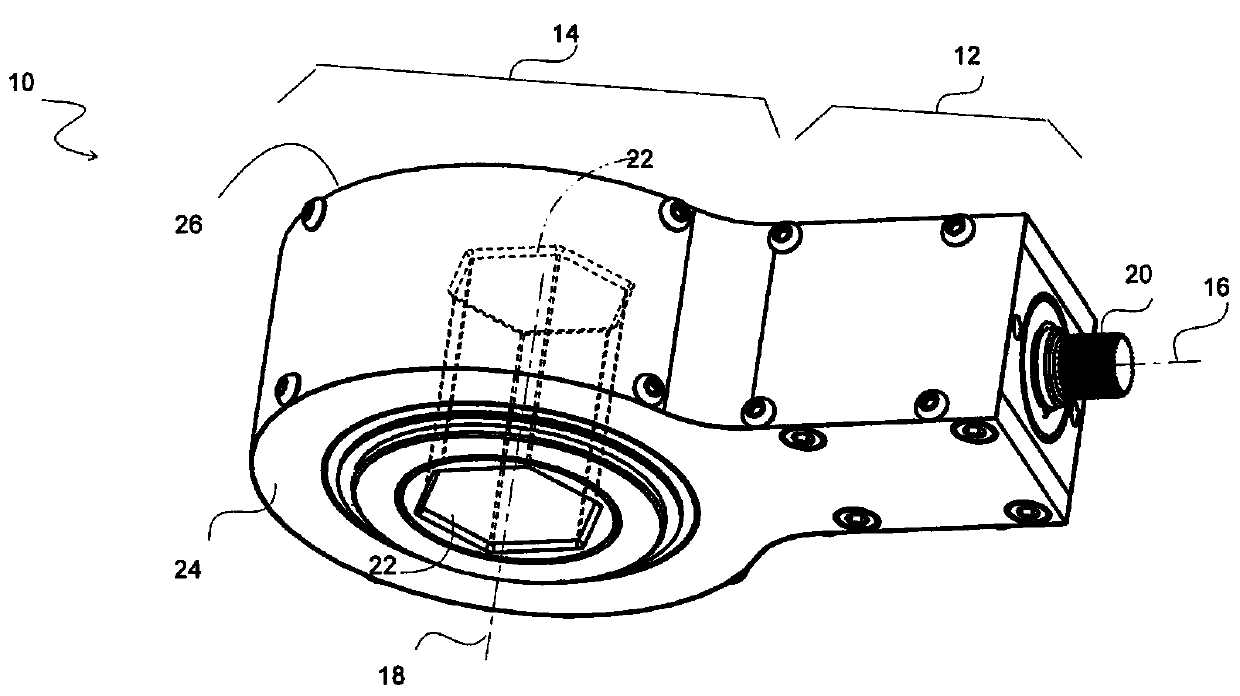

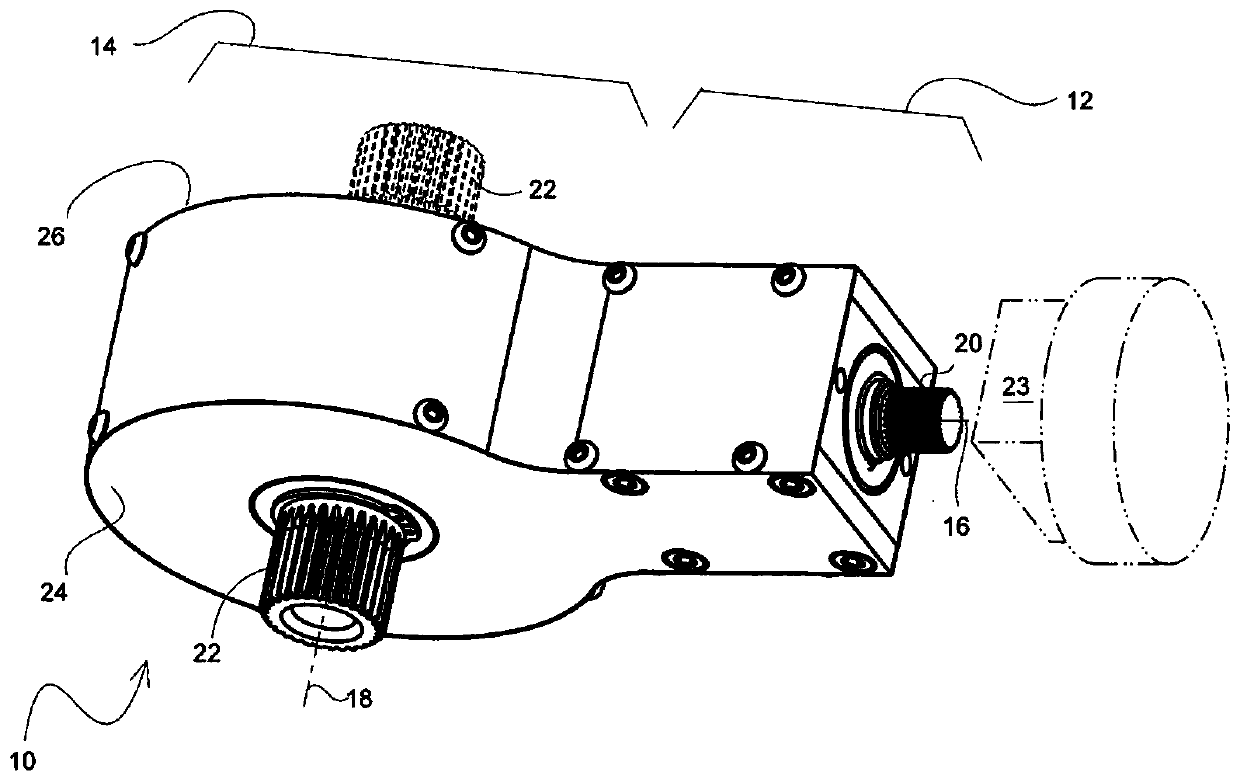

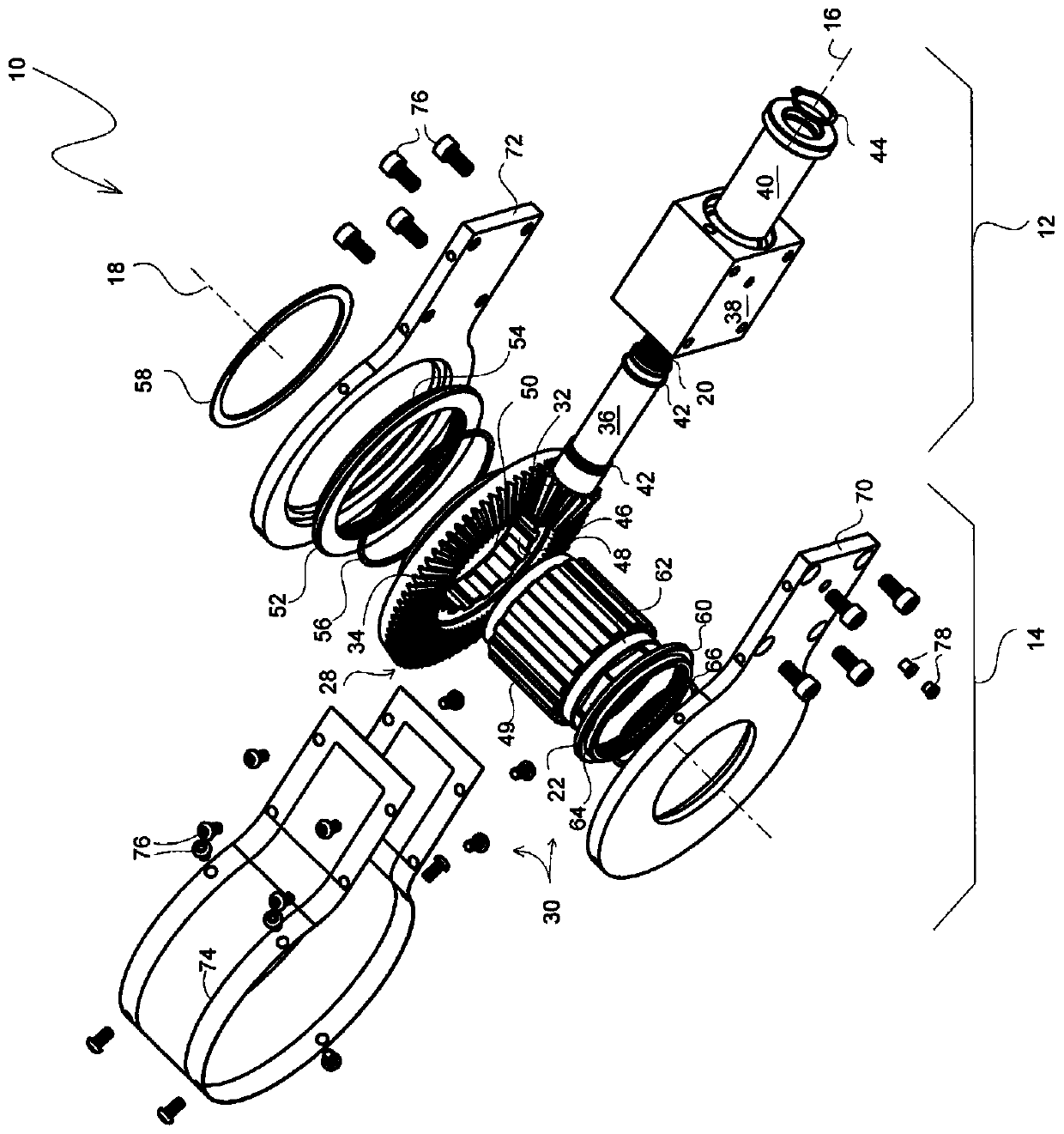

[0020] figure 1 and figure 2 Variations of an exemplary torque wrench ("wrench") 10 are described that may be used to loosen or tighten fasteners (eg, bolts having heads with internal and / or external engagement features - not shown) . The wrench 10 can generally be divided into an input 12 and an output 14 . Input 12 may be configured to receive a continuous torsional input (eg, from a manually operated lever or from an electric, hydraulic or pneumatic motor), which is then converted to a continuous torsional output at output 14 . The twist input can be generally aligned with the first axis 16 of the wrench 10 , and the twist output can be generally aligned with the second axis 18 that is substantially (eg, within 0-10°) perpendicular to the first axis 18 . The input 12 may include a mating interface (eg, socket, spline, Torx or square root, etc.) 20 configured to mate with a corresponding mating interface of a rod or motor and receive a torsional input. The output 14 may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com