Micromechanical device with covering bond frame

A micro-mechanical and micro-mechanical structure technology, applied in the direction of micro-structural devices composed of deformable elements, micro-structural technology, micro-structural devices, etc., can solve problems such as expensive structures, reduce manufacturing costs, improve performance, The effect of reducing chip area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

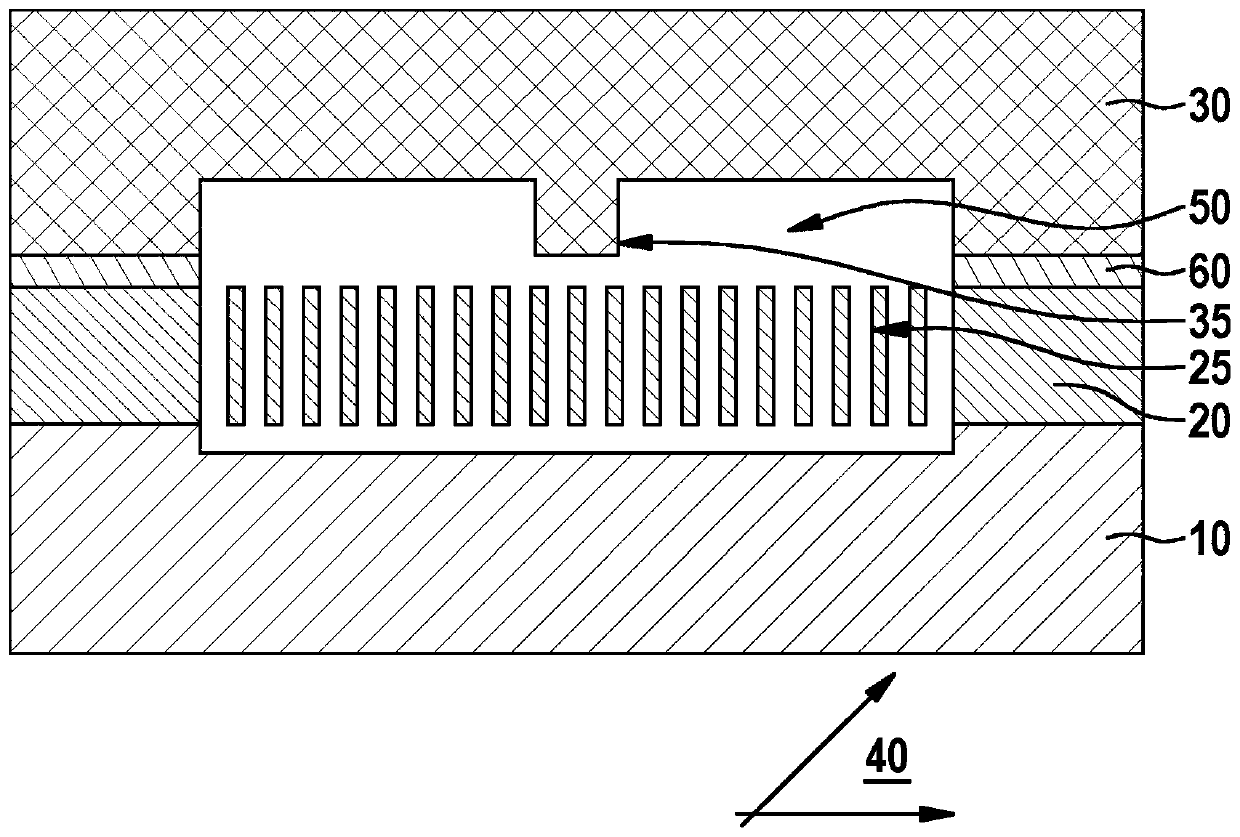

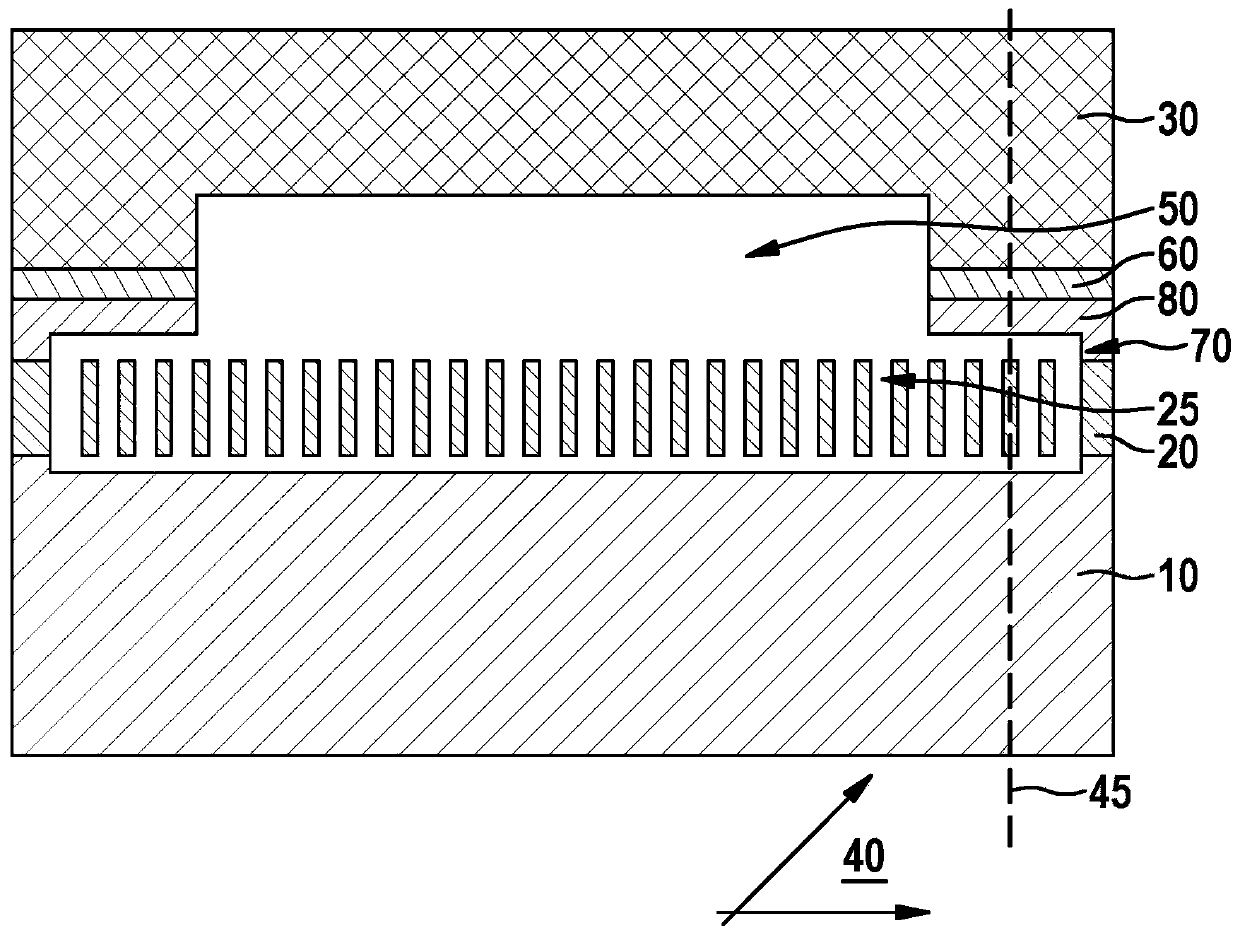

[0024] A schematic comparison of a prior art micromechanical device and a micromechanical device according to the invention with a covered bond frame is shown in cross section in FIGS. 1 and 2 .

[0025] FIG. 1 shows a prior art micromechanical device with a substrate, a micromechanical structure, a bond frame and a cover. Shown is a micromechanical device with a substrate 10 , a functional layer 20 and a cover 30 arranged one above the other parallel to the main plane of extent 40 . In this case, a cavity 50 is formed in the functional layer 20 , which cavity is surrounded by a bonding frame 60 . A micromechanical structure 25 is also formed in the functional layer 20 . The cover 30 is connected to the key frame 60 . The cover 30 has a cover stop 35 for delimiting the offset of the functional layer 20 perpendicular to the main plane of extent 40 .

[0026] figure 2 A micromechanical device according to the invention is shown with a substrate, a micromechanical structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com