Angle sensor with a ring waveguide as a physical measure

An angle sensor and waveguide technology, which is used in the transmission of sensing components, instruments, tire measurements, etc. using wave/particle radiation devices, which can solve the problems of complex manufacturing of microstructure technology and small structure size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

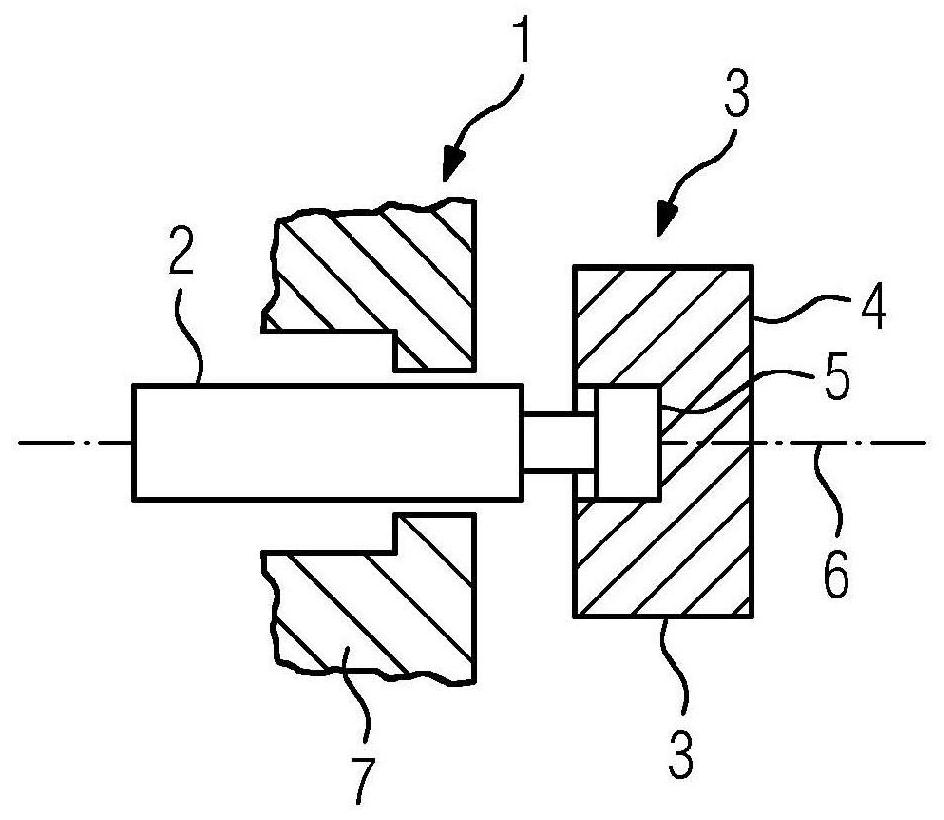

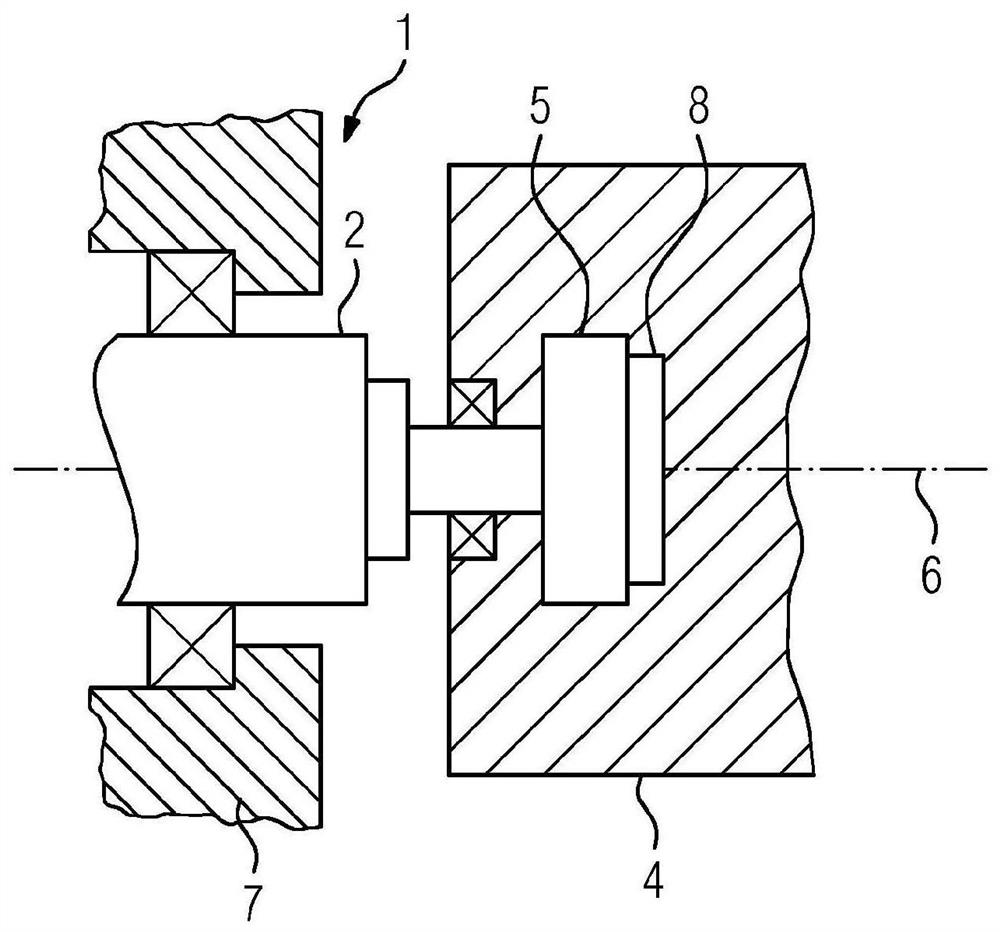

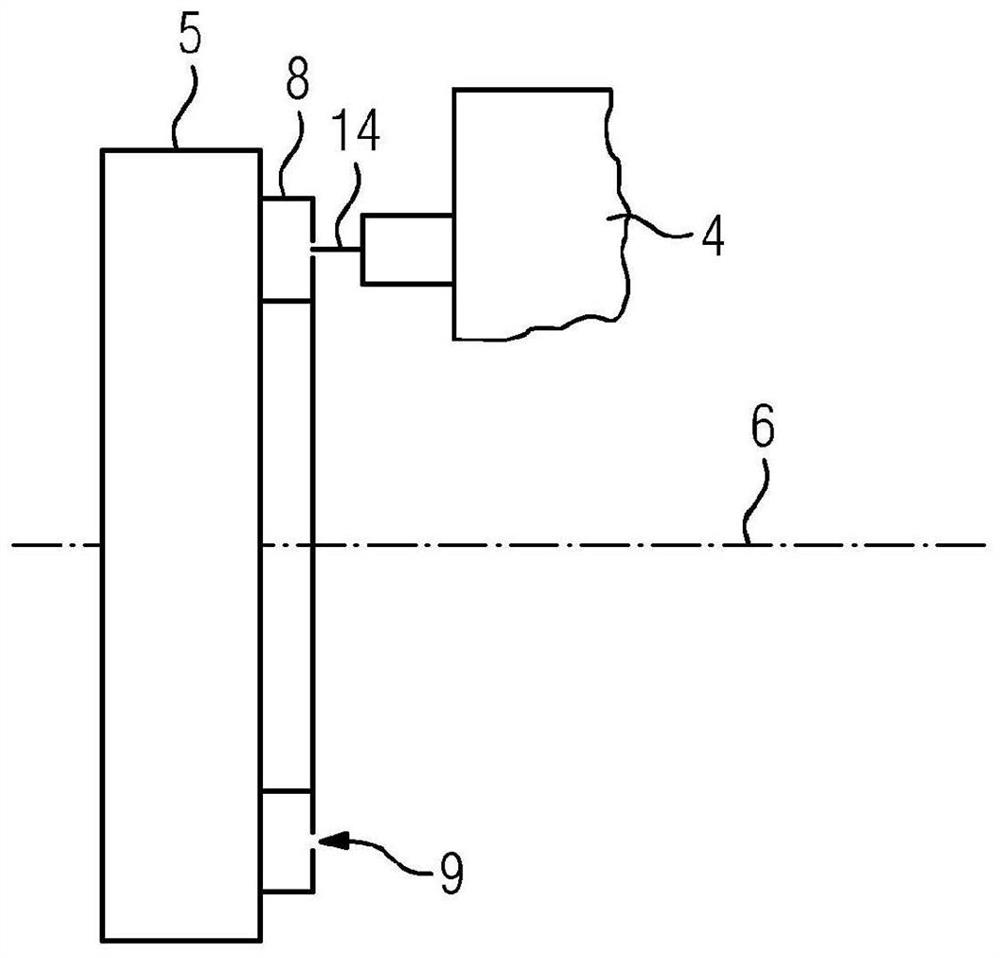

[0057] according to figure 1 , the machine 1 has a shaft 2, and what is to be detected is the rotational angle or rotational position α of the shaft. An angle sensor 3 is provided for this purpose. according to figure 1 with figure 2 , the angle sensor 3 has a base body 4 in which a rotating element 5 is mounted. As a result, the rotary element 5 can be rotated about the axis of rotation 6 , ie the rotary element can be rotated by any angle greater and smaller than 360°. Thus, the rotary element 5 can in principle rotate through any desired number of full revolutions. The basic body 4 can be connected to the housing 7 of the machine 1 , for example via screws. The rotary element 5 can be connected to the shaft 2 of the machine 1 , for example likewise via screws. The connection of the rotary element 5 to the shaft 2 of the machine 1 is realized in such a way that the axis of rotation 6 coincides with the axis of rotation of the shaft 2 of the machine 1 as well as possib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com