Feeding machine for feeding and having automatic replenishment function

An automatic replenishment and feeding machine technology, applied in animal feeding devices, applications, poultry industry, etc., can solve the problems of feed quality decline, pollution, waste and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

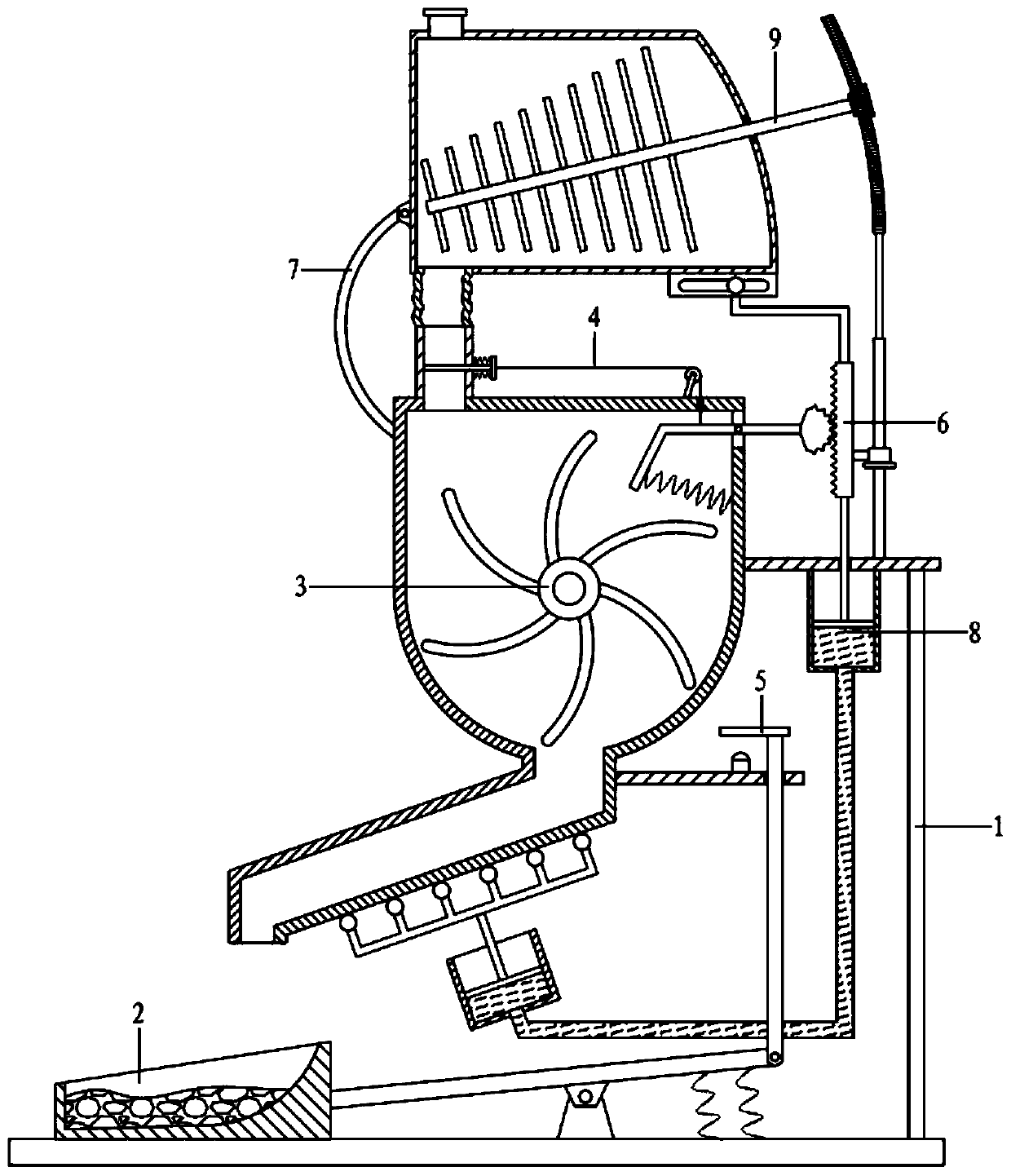

[0057] With reference to the accompanying drawings, a feeding machine with automatic replenishment function includes a frame assembly 1, an induction assembly 2, a bulk assembly 3, a feeding assembly 4, a start-stop assembly 5, a lifting assembly 6 and a shaking assembly 7;

[0058] The frame assembly 1 includes a base 101, a No. 1 support rod 102, a No. 1 support plate 103, a breaking chamber 104, a feeding pipe 105 and a storage box 106; the No. 1 support plate 103 is arranged above the base 101, and the two The right end of the person is connected by No. 1 support rod 102; the left end of the No. 1 support plate 103 is connected with a break-up chamber 104; The pipeline communicates with the material storage box 106, and is provided with a blanking assembly 4; the bulk material assembly 3 is provided in the said breaking chamber 104; a lifting assembly 6 is provided on the No. 1 support plate 103, and the blanking assembly 4 passes through the lifting Component 6 cooperates...

Embodiment 2

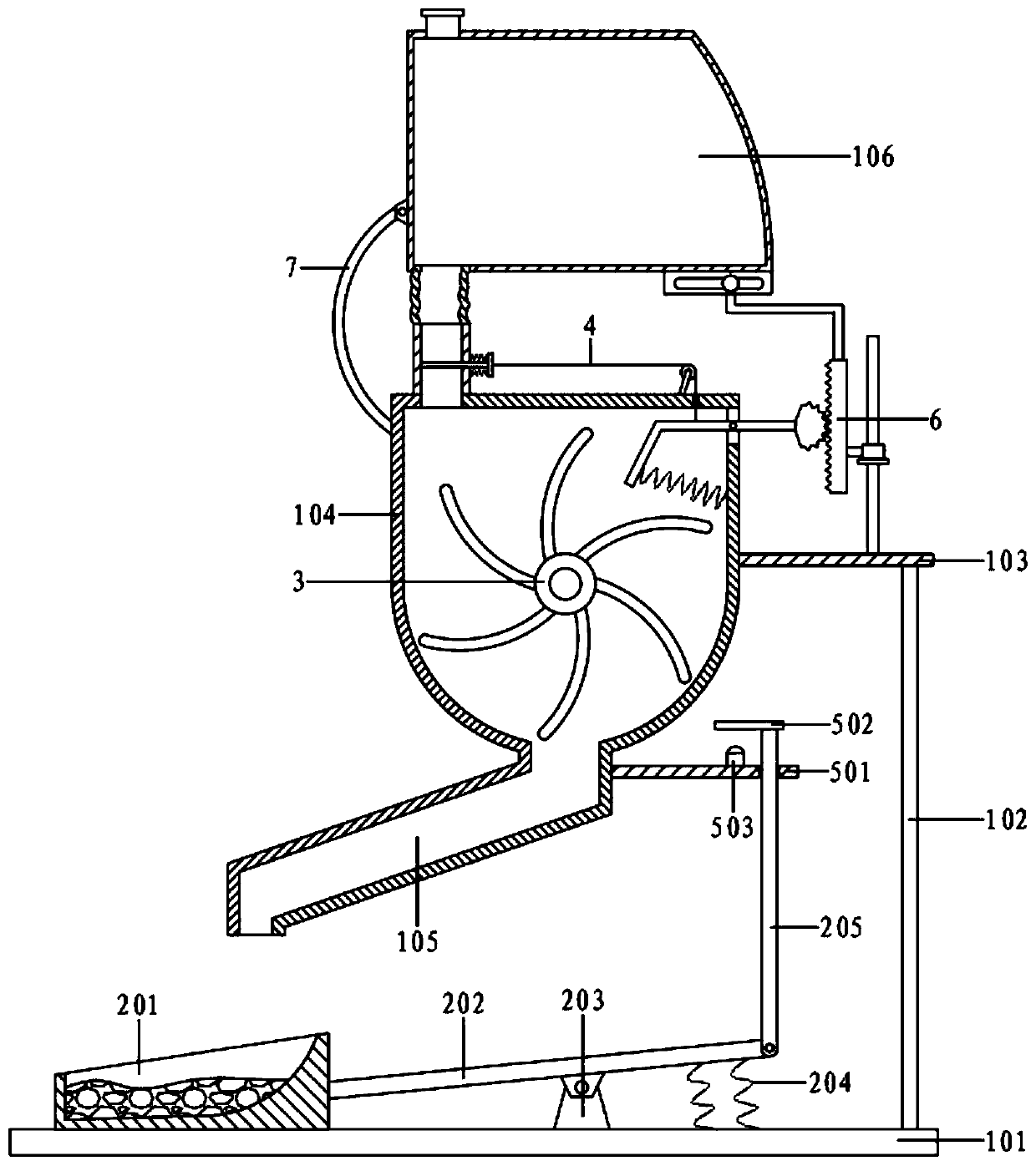

[0060] With reference to the accompanying drawings, a feeding machine with automatic replenishment function includes a frame assembly 1, an induction assembly 2, a bulk assembly 3, a feeding assembly 4, a start-stop assembly 5, a lifting assembly 6 and a shaking assembly 7;

[0061] The frame assembly 1 includes a base 101, a No. 1 support rod 102, a No. 1 support plate 103, a breaking chamber 104, a feeding pipe 105 and a storage box 106; the No. 1 support plate 103 is arranged above the base 101, and the two The right end of the person is connected by No. 1 support rod 102; the left end of the No. 1 support plate 103 is connected with a break-up chamber 104; The pipeline communicates with the material storage box 106, and is provided with a blanking assembly 4; the bulk material assembly 3 is provided in the said breaking chamber 104; a lifting assembly 6 is provided on the No. 1 support plate 103, and the blanking assembly 4 passes through the lifting Component 6 cooperates...

Embodiment 3

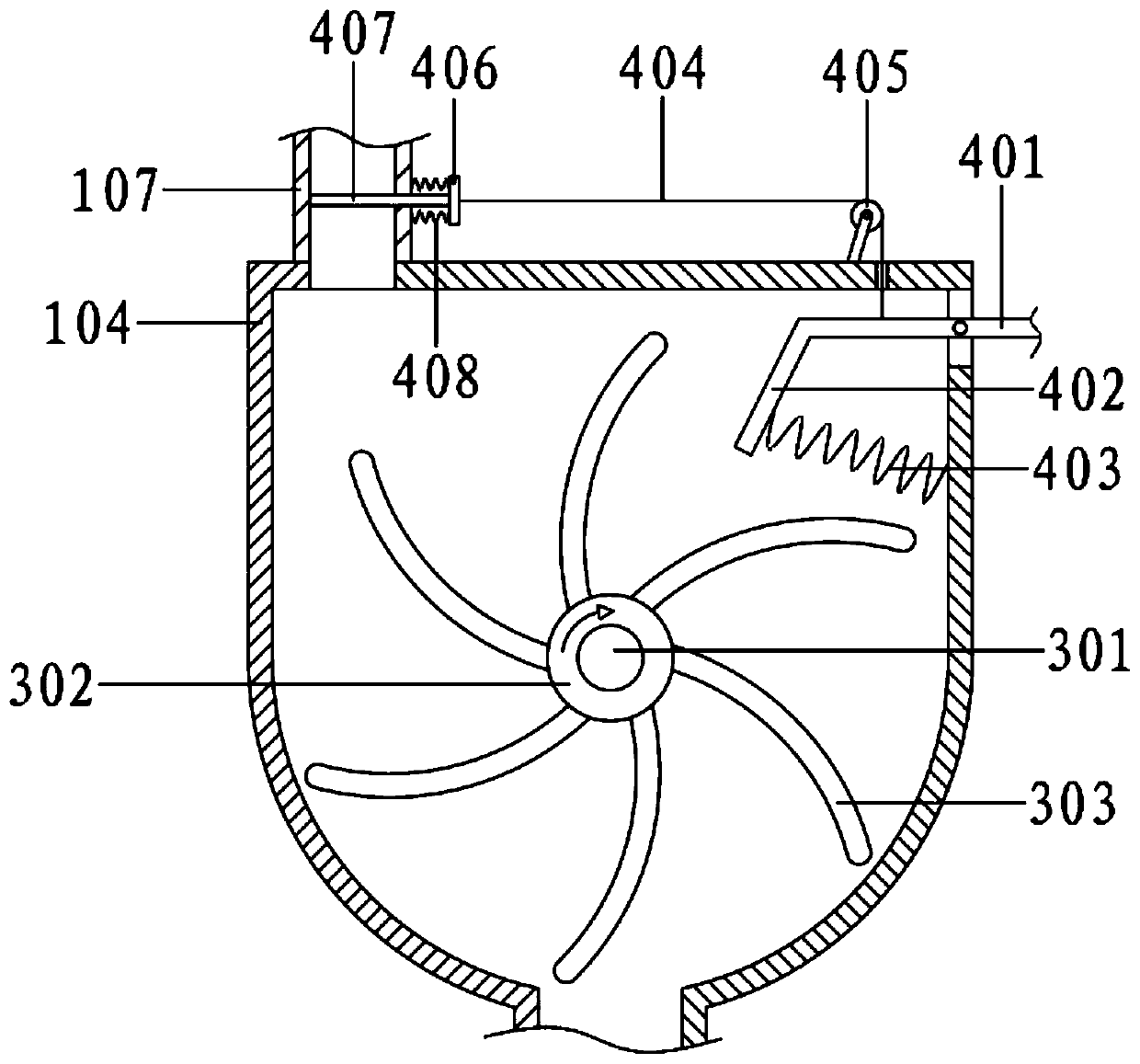

[0081] On the basis of embodiment 2,

[0082] It also includes a stirring assembly 9; the stirring assembly 9 includes a third connecting rod 901, an arc-shaped rack 902, a driven gear 903, a second rotating shaft 904 and a stirring rod 905;

[0083] The top of the slide bar 604 is connected to the arc rack 902 through the third connecting rod 901, and the center of the circle corresponding to the arc rack 902 coincides with the hinge point at the top of the second support rod 701; the arc rack 902 is equipped with Driven gear 903; said driven gear 903 is installed on the right end of the second rotating shaft 904, and the second rotating shaft 904 passes through the right side wall of the material storage box 106 and goes deep into the material storage box 106; said second rotating shaft 904 is connected with The stirring rod 905 is located in the material storage box 106 .

[0084] Specifically, when the material storage box 106 shakes, the driven gear 903 and the arc-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com