Food processing device

A technology for food processing and installation of shells, which is applied in food forming, mixers with rotating stirring devices, applications, etc. It can solve the problems of reducing food processing efficiency, not being able to add liquid raw materials, and increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

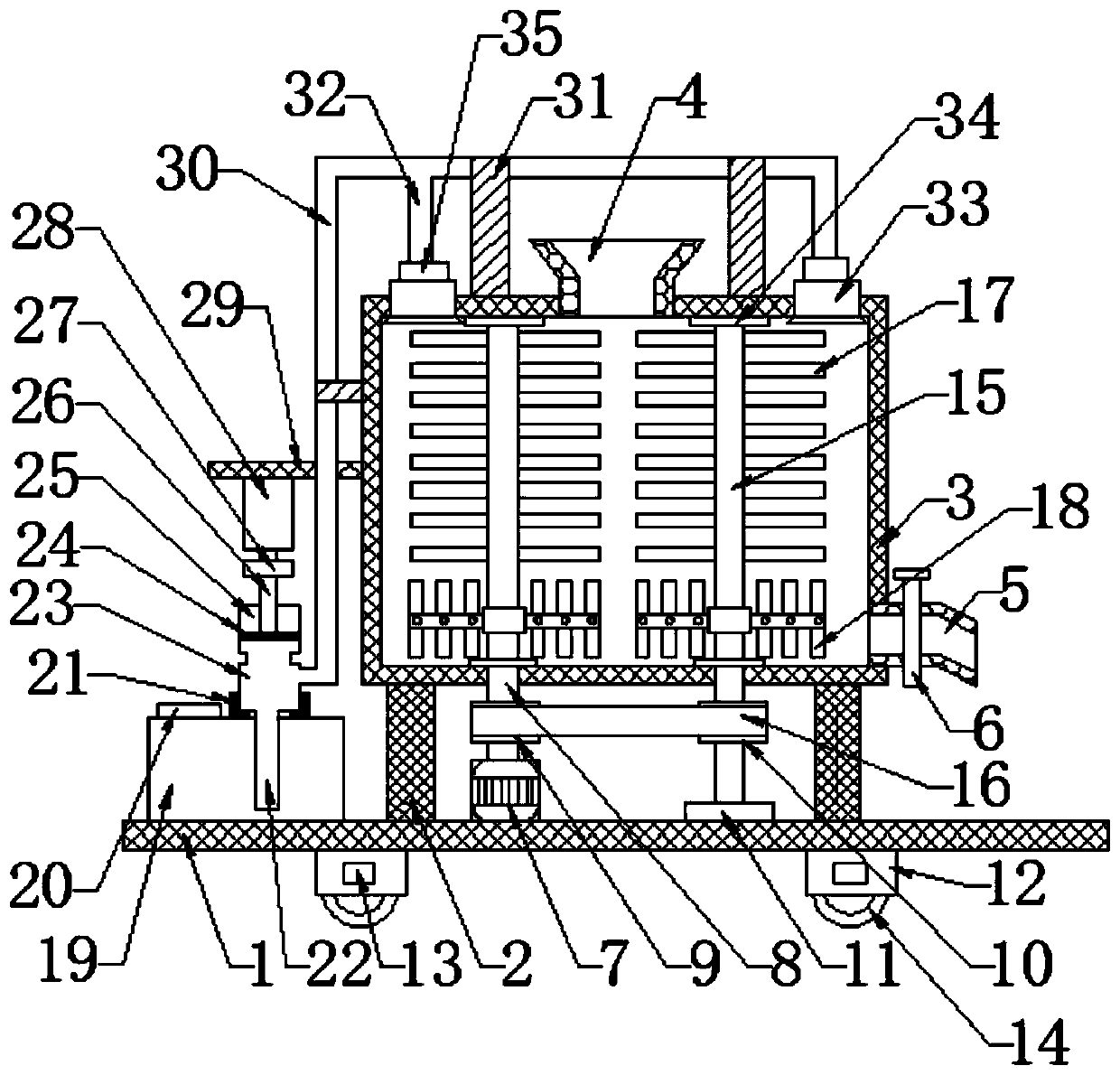

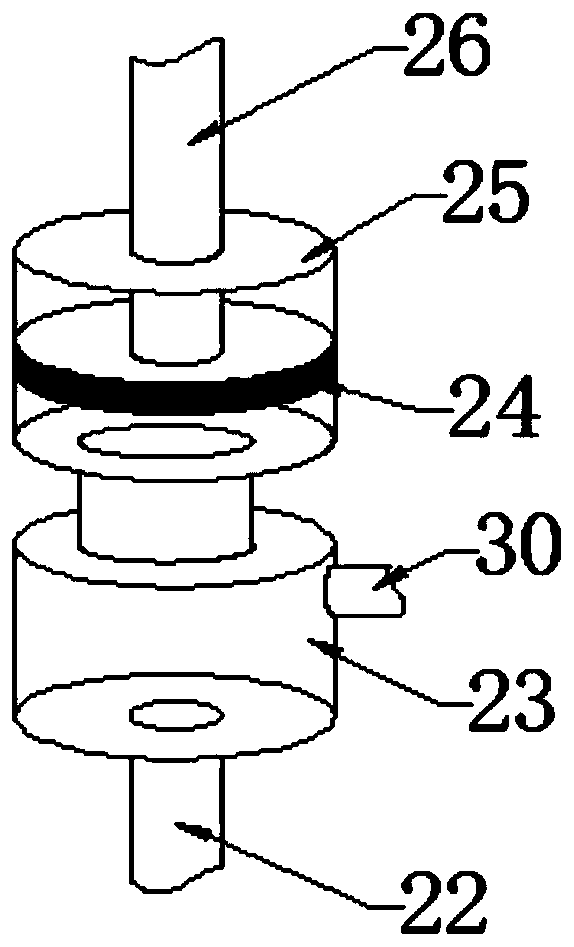

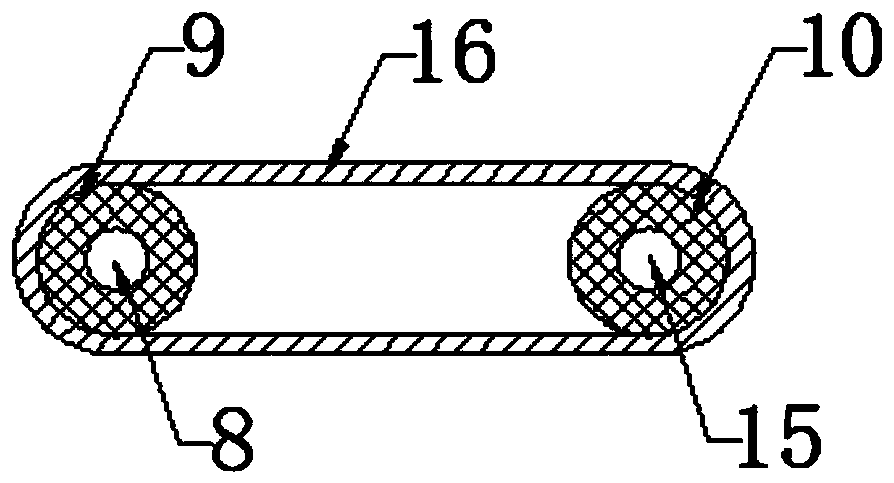

[0024] see Figure 1~3 , in an embodiment of the present invention, a food processing device includes a base 1, a support 2 and a mixing chamber 3, the support 2 is fixedly mounted on the base 1, and the stirring chamber 3 is fixedly mounted on the support 2; A motor 7 is also fixedly installed on the base 1, and the output end of the motor 7 is fixedly connected with a first stirring shaft 8, and a driving wheel 9 is fixedly installed on the first stirring shaft 8; Fixed block 11 is arranged, and described fixed block 11 is positioned at motor 7 side, and the second agitating shaft 15 is installed in rotation in described fixed block 11, and driven wheel 10 is fixedly installed on described second agitating shaft 15; 9 and the driven wheel 10 are provided with the same belt 16; the first stirring shaft 8 and the second stirring shaft 15 pass through the lower wall of the stirring chamber 3 and extend to the inner top of the stirring chamber 3, and the inner wall of the upper ...

Embodiment 2

[0033] see figure 1, in order to avoid the phenomenon that raw materials are deposited on the bottom during the stirring process of the food processing device of the present invention, this embodiment has been further improved on the basis of embodiment 1. The improvement is: the first stirring shaft 8 and the second stirring shaft 15 are also fixedly equipped with a bottom stirrer 18, which is located below the stirring blade 17; the bottom stirrer 18 is composed of a horizontal stirring rod and several Consists of a vertical stirring rod.

[0034] The working principle of the present invention is:

[0035] When using the food processing device of the present invention, the device is first moved to a suitable position by the moving wheel 14, and then the brake 13 is adjusted so that the moving wheel 14 is braked, so that the device is fixed on the suitable position; the raw material to be stirred Add in the stirring chamber 3 from the feed port 4, simultaneously add the liq...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap