A 3D printing sanding mechanism

A technology of 3D printing and sanding rollers, which is applied in the direction of ceramic molding machines, casting molding equipment, casting mold components, etc., can solve the problem of increasing the scrapping rate of sand molds, the inability to guarantee the amount of sand output and the uniformity of sand laying, and affecting the quality of sand laying sand molds Printing effect and other issues, to achieve the effect of uniform sanding and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in conjunction with the following application scenarios.

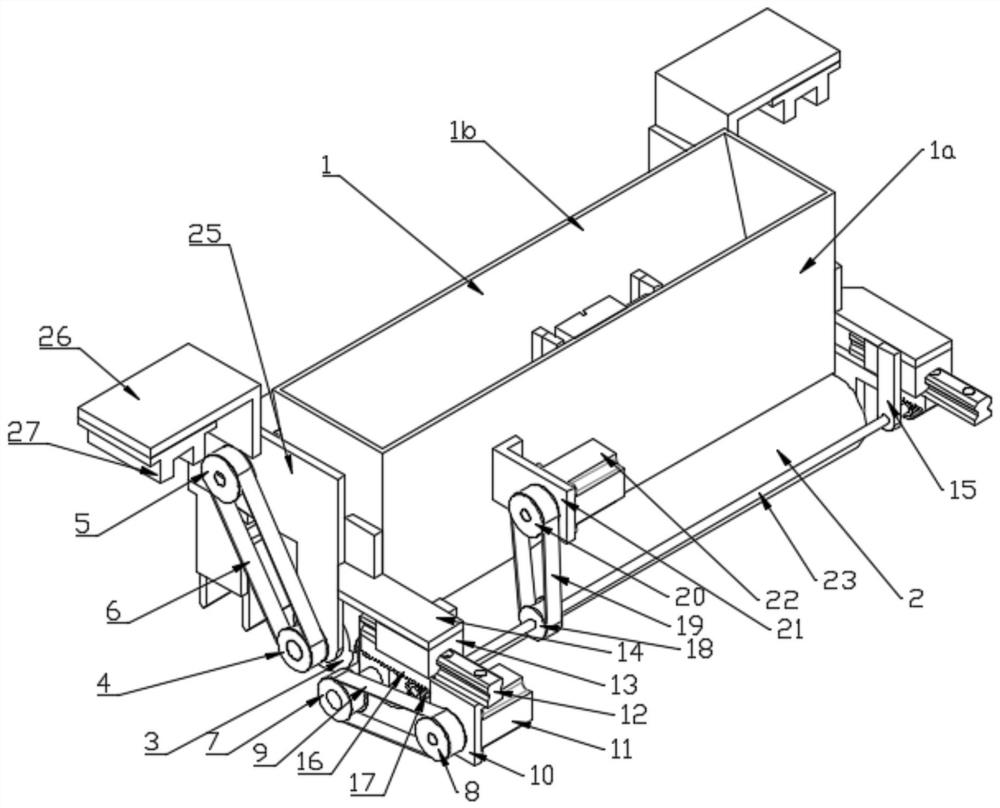

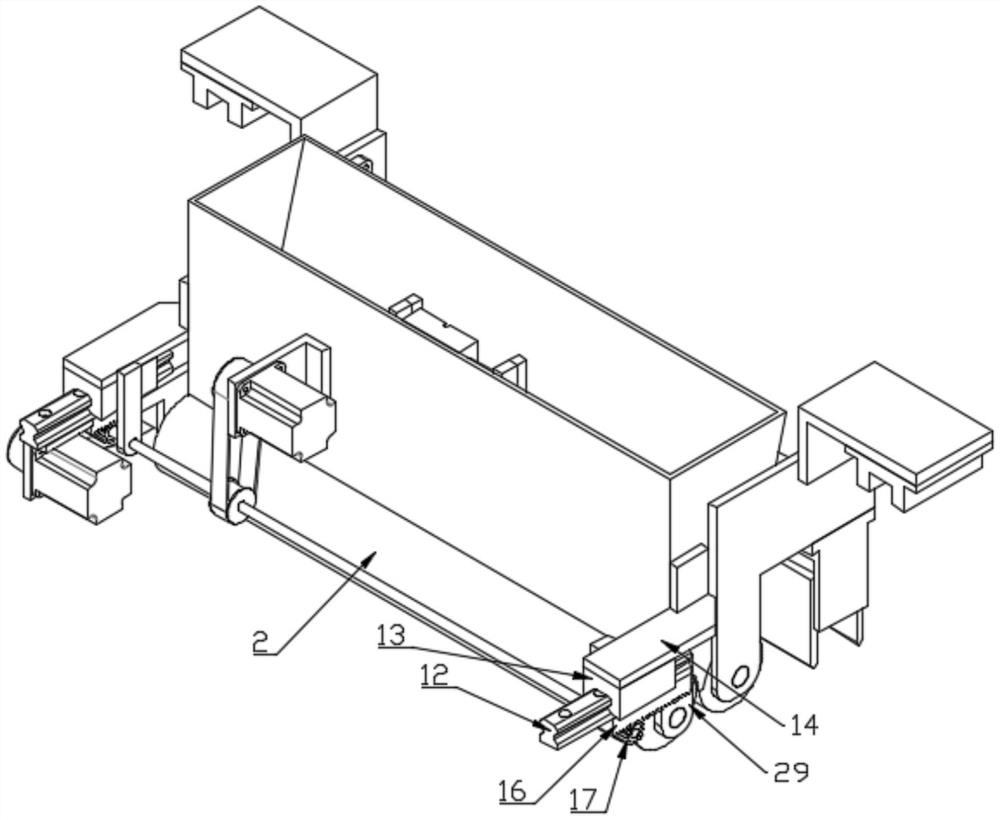

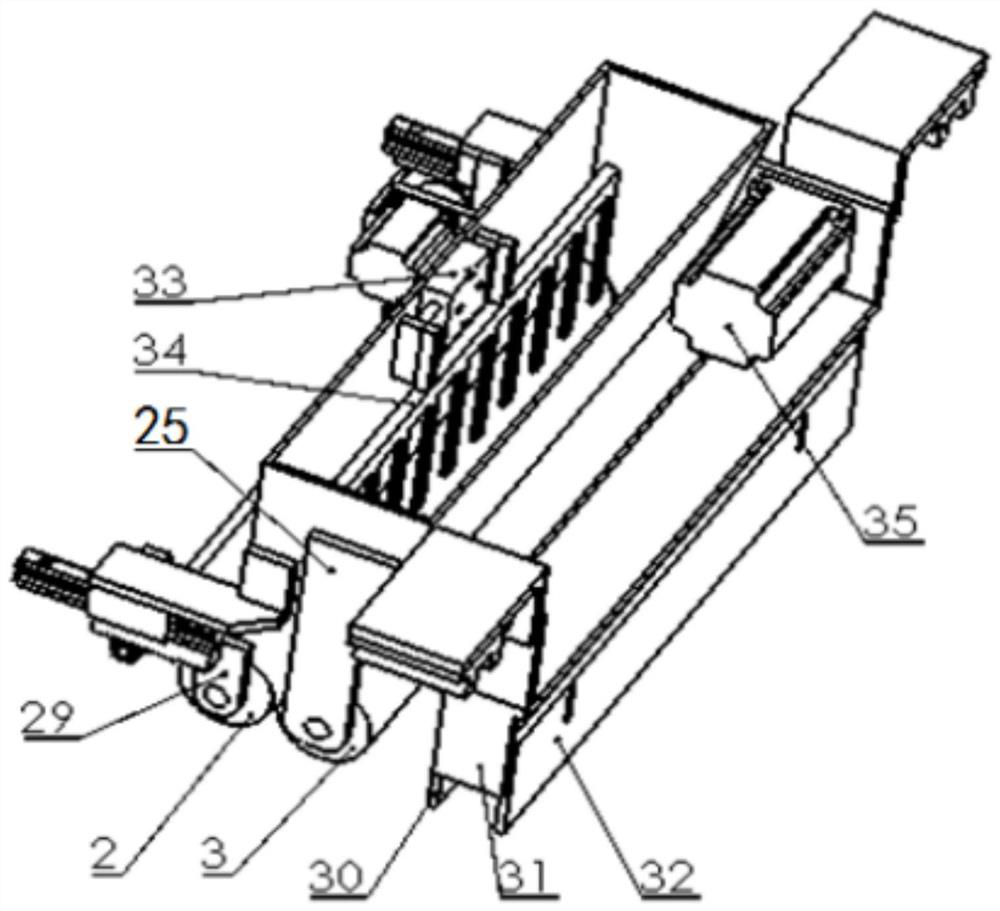

[0030] see Figure 1 to Figure 4 , which shows a 3D printing sand spreading mechanism, including a sand storage bucket 1, wherein the sand storage bucket 1 is surrounded by a front panel 1a, a rear panel 1b and two side panels, and the upper part of the sand storage bucket 1 is provided with a sand supply port, The lower part of the sand storage bucket 1 is provided with a sand outlet with a fixed width along the left and right directions, and the front panel 1a and the rear panel 1b above the sand outlet have a V-shaped section along the front and rear directions; wherein:

[0031] The bottom of the lower end of the rear panel 1b is provided with a rear lower emery roller 3 arranged in the left-right direction, wherein the lower end of the rear panel 1b faces the roller surface of the rear lower emery roller 3, and the left and right ends of the rear lower emery r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com