Organoantimony crosslinking agent and its preparation method and cleaning fracturing fluid

A technology of cross-linking agent and organic antimony, which is applied in the field of organic antimony cross-linking agent and its preparation, and clean fracturing fluid, which can solve problems such as difficult to solve the performance requirements of construction-scale fracturing fluid, restrictions on wide application, and impact on fracturing effects , to achieve the effect of controlling the crack height, uniform sanding, and no protrusion in the rheological curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Another embodiment of the present invention proposes a preparation method of an organic antimony crosslinking agent, which includes the following steps:

[0056] 1) Synthesis of polyol antimonate: add sorbitol in isopropanol solvent, add antimony trichloride dropwise with stirring at 20°C-30°C, pass through ammonia gas to react for 90-120min, after the reaction, filter and distill , refined to obtain polyol antimonate;

[0057] 2) Add the polyol antimonate to triethanolamine under stirring state, react at 120-150° C. for 60-90 minutes, distill and refine after the reaction to obtain an organic antimony cross-linking agent.

[0058] The weight ratio of isopropanol, sorbitol, antimony trichloride and triethanolamine in the preparation method of the organic antimony crosslinking agent in the embodiment of the present invention is 50-70:10-30:5-10:10-30.

[0059] The dropping time of antimony trichloride in the preparation method of the organic antimony crosslinking agent ...

Embodiment 1

[0073] 1) Synthesis of polyol antimonate: Add 68g of sorbitol into 240g of isopropanol solvent, add 32g of antimony trichloride dropwise with stirring at 30°C, the antimony trichloride is added dropwise within 20min, and then pass through ammonia gas, React at 30°C for 120 minutes. After the reaction, remove ammonium chloride by filtration, and the filtrate is distilled and refined to obtain triethanolamine polyol antimonate crosslinking agent, which is polyol antimonate;

[0074] 2) Add the above-mentioned polyol antimonate to 60 g of triethanolamine under stirring, and react at 140° C. for 90 min. After the reaction, distill and refine to obtain an organic antimony crosslinking agent.

Embodiment 2

[0076] 1) Synthesis of polyol antimonate: Add 14g of sorbitol to 122g of isopropanol solvent, add 16g of antimony trichloride dropwise with stirring at 25°C, the antimony trichloride is added dropwise within 20min, and ammonia gas is passed in, React at 30°C for 90 minutes. After the reaction, remove ammonium chloride by filtration, and the filtrate is distilled and refined to obtain triethanolamine polyol antimonate crosslinking agent, which is polyol antimonate;

[0077] 2) Add the polyol antimonate to 48 g of triethanolamine under stirring, react at 120° C. for 70 min, distill and refine after the reaction to obtain an organic antimony crosslinking agent.

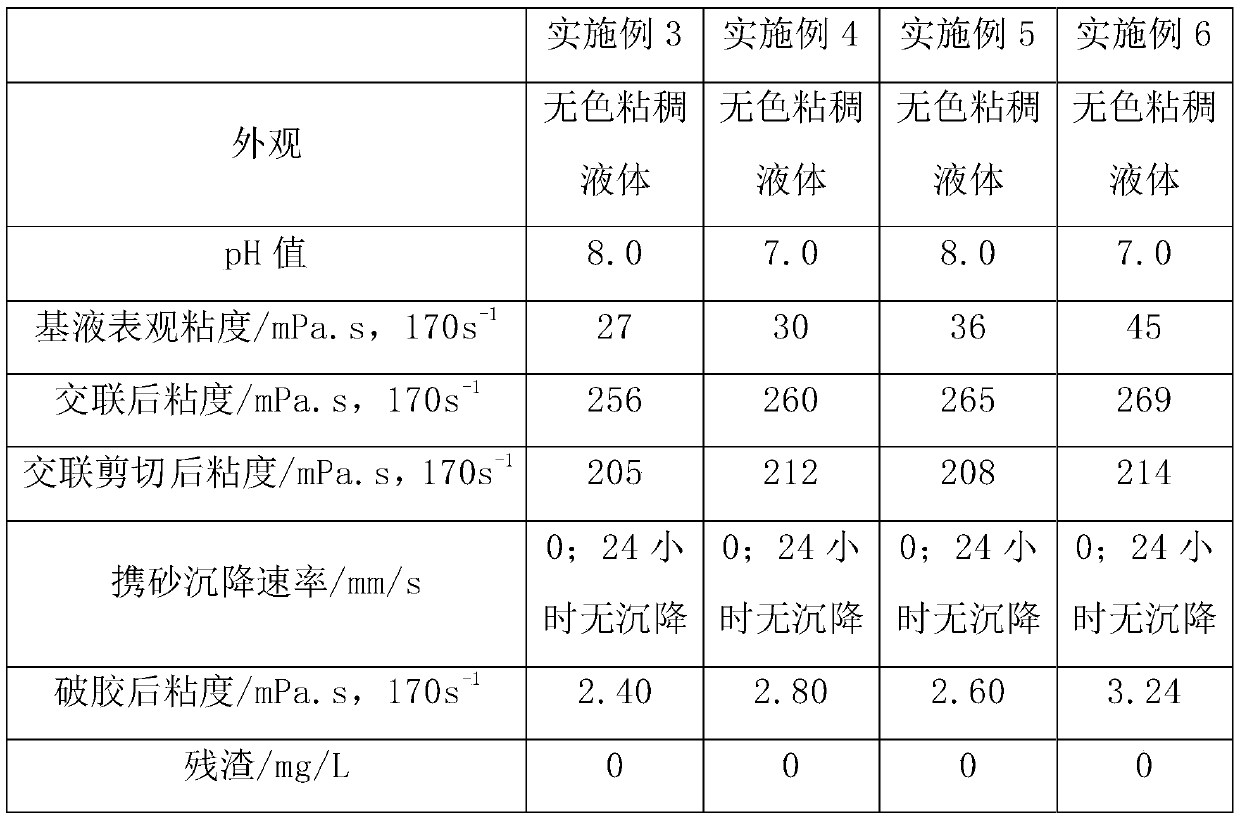

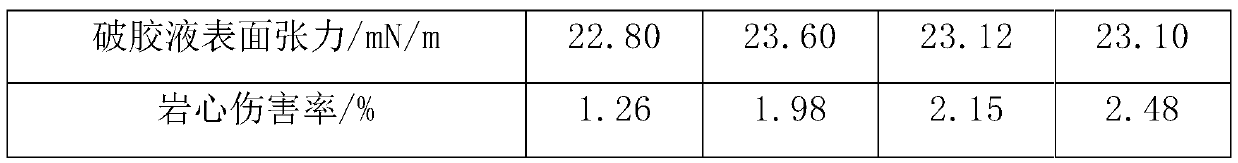

[0078] The organic antimony crosslinking agent in the clean fracturing fluid components of Examples 3-6 is the organic antimony crosslinking agent prepared in Example 1. Table 1 shows the components of the clean fracturing fluids of Examples 3-6.

[0079] The composition (percentage by weight) of the clean fracturing fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com