A kind of preparation method of high barrier and high swelling resistance lithium ion battery shell

A lithium-ion battery and battery casing technology, applied in other household appliances, household appliances, household components, etc., can solve the problems of low resistance to electrolyte swelling and poor barrier performance, improve the use effect and service life, and avoid energy. Loss of consumption efficiency and effect of high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

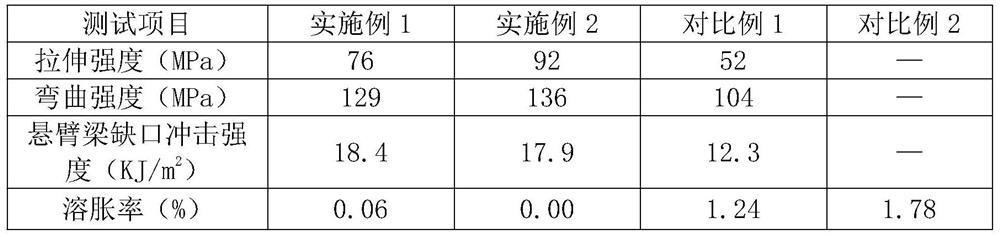

Examples

Embodiment 1

[0029] The polypropylene composite material of this embodiment is composed of the following components by weight: 75 parts of PP, 5 parts of HDPE, 5 parts of glass fiber, 0.5 part of nucleating agent, 0.5 part of compatibilizer, 0.1 part of antioxidant, 0.5 part of toughening agent 0.1 part of lubricant, 0.1 part of dispersant, 0.1 part of coupling agent.

[0030] The above-mentioned polypropylene composite materials are modified as follows:

[0031] (1) The glass fiber is coated with a silane coupling agent.

[0032] (2) Put the nucleating agent, toughening agent, dispersing agent, antioxidant, compatibilizer, and lubricant into the low-speed mixer according to the proportion and mix for 1-3min, then put PP and HDPE into the low-speed mixer and mix at least 2- 3min, wherein the rotating speed of the low-speed mixer is 90 rev / min.

[0033] (3) adding the mixture obtained in the step (2) from the main feeding port of the twin-screw extruder, adding the glass fiber obtained in...

Embodiment 2

[0041] The polypropylene composite material of this embodiment is composed of the following components by weight: 90 parts of PP, 25 parts of HDPE, 20 parts of glass fiber, 0.6 parts of nucleating agent, 0.7 part of compatibilizer, 0.1 part of antioxidant, 0.5 part of toughening agent part, 0.2 part of lubricant, 0.3 part of dispersant, and 0.2 part of coupling agent.

[0042] The polypropylene composite material was obtained according to the method of Example 1.

[0043] The above-mentioned polypropylene composite material is made into a high-barrier and high-swelling-resistant lithium-ion battery shell according to an injection molding process. The injection molding process includes an injection molding process and a pressure holding process. The injection molding process parameters are high injection pressure and low injection speed. The steps are as follows:

[0044] Step 1. Set the temperature of the injection barrel of the injection molding machine as follows: the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com