Rail belt conveyor system

A technology of ground transportation and conveyor, which is applied in the field of track-ground conveyor-system, can solve disadvantages and other problems, achieve the effect of improving stability and avoiding position change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

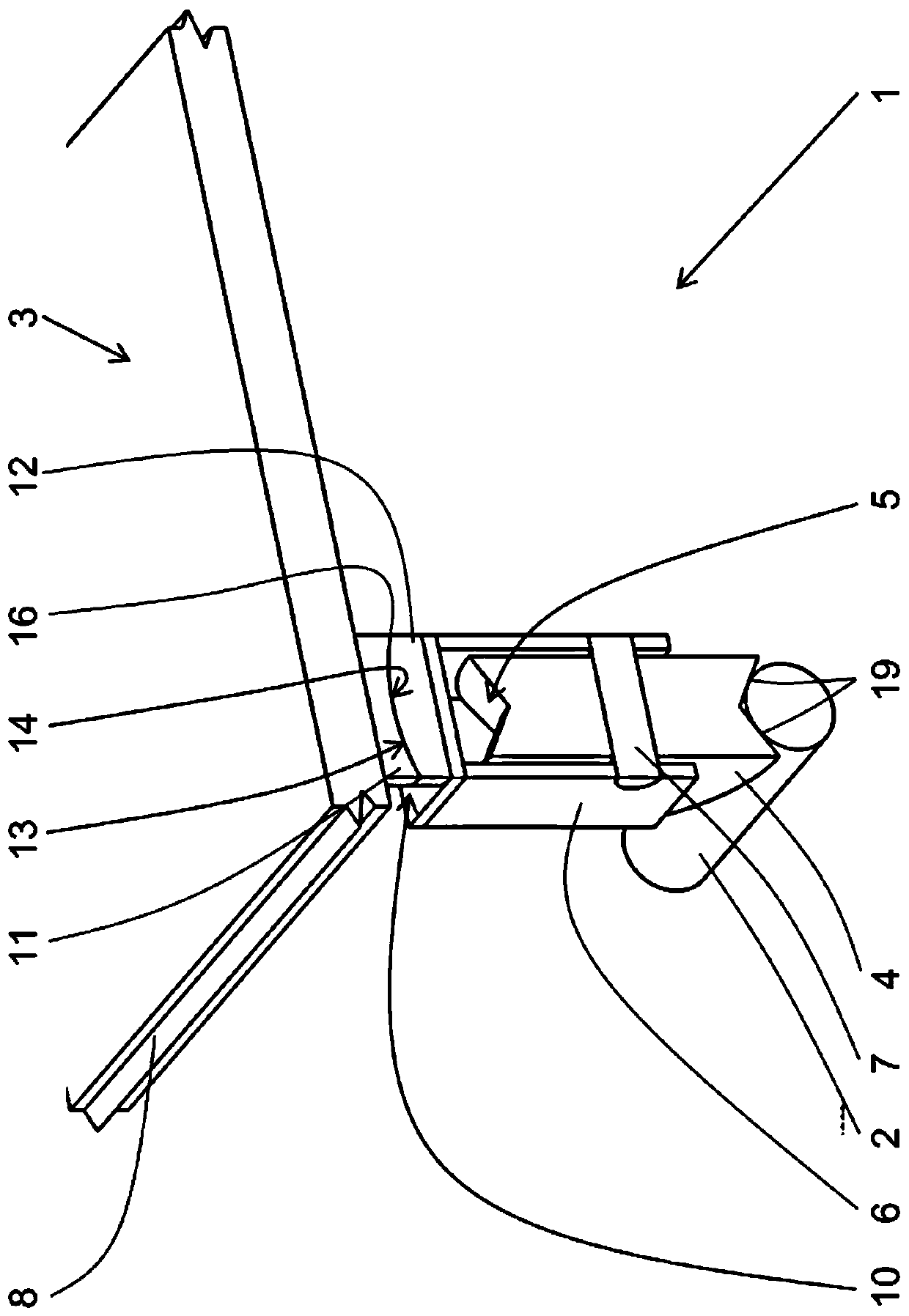

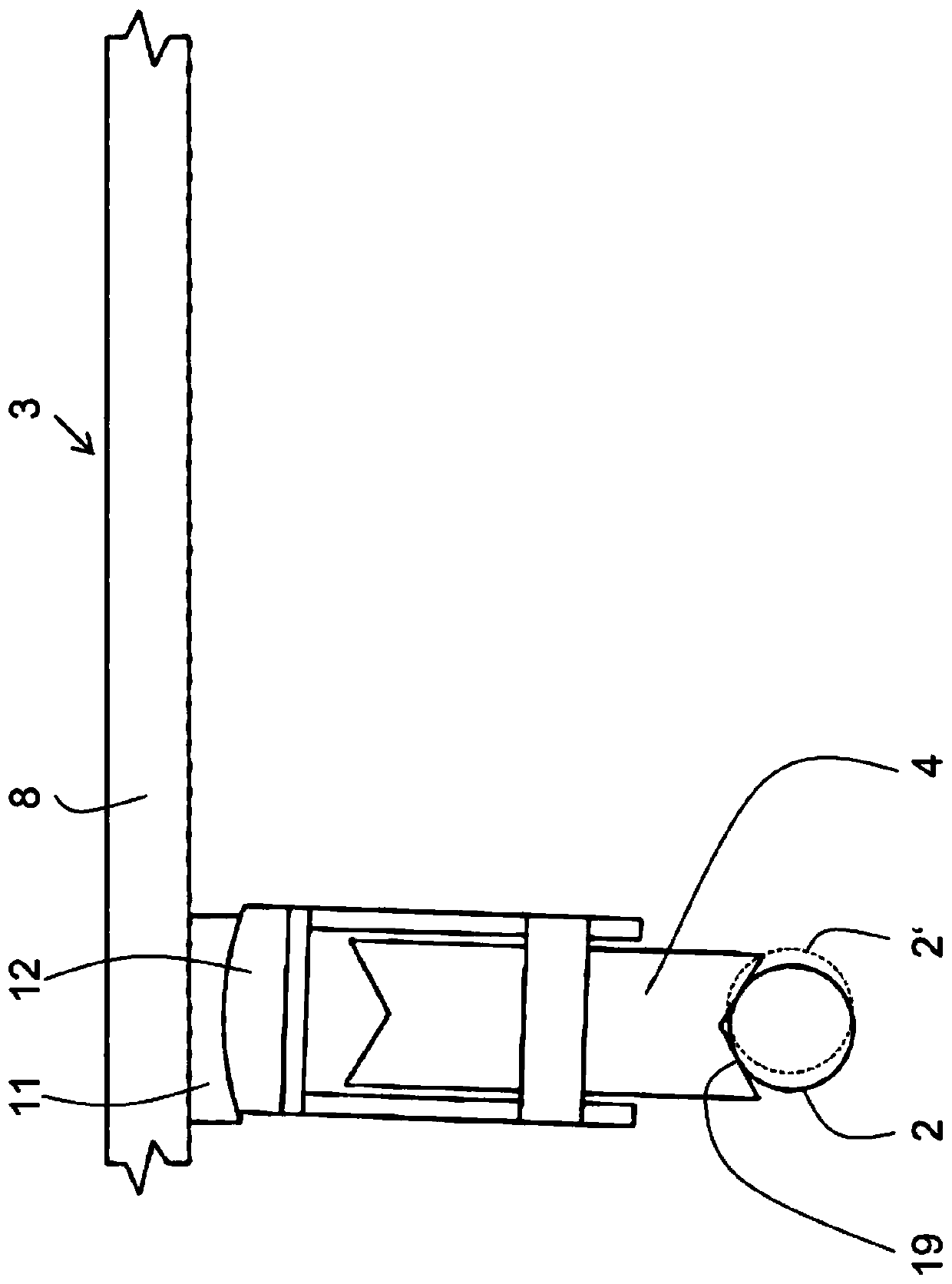

[0044] In order to better display the characteristics, in Figure 2 to Figure 6 A vertical section was made in the middle. For intuitive reasons, (except for the elastomer layer) hatching is also omitted.

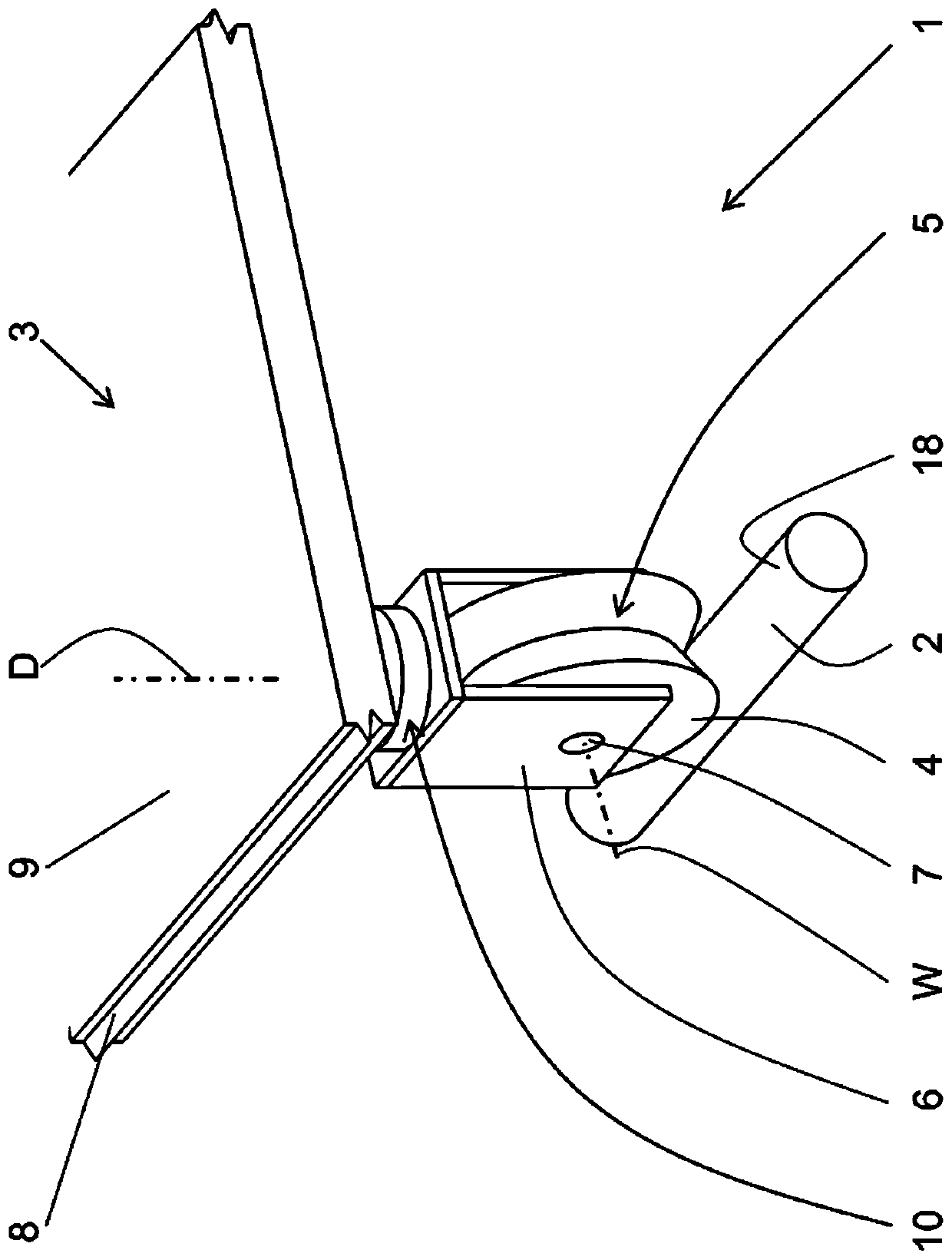

[0045] figure 1 An example of the basic structure of the track-ground conveyor-system 1 is shown. Here, only one corner of the ground conveyor 3 and a section of the circular track 2 are shown. The ground conveyor 3 has a supporting structure 8 on which a loading surface 9 is provided.

[0046] In this embodiment, a bearing 10 is provided on the corner of the supporting structure, and a wheel support 6 having at least one wheel is supported in the bearing around a vertical rotation axis D. The wheel (or more than one) has an axle 7 which also constitutes a horizontal rotation axis W about which the wheel can rotate.

[0047] in figure 2 Shows through figure 1 Vertical section of the bearings, wheels and rails. It can be clearly seen here that the bearing 10 is divided into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com