A paste filling material for mine filling mining

A paste filling and mine filling technology, applied in the field of paste filling materials, can solve problems such as high cost of long-distance transportation, insufficient filling materials, and inability to apply filling mining technology, and achieve the effect of avoiding land occupation and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

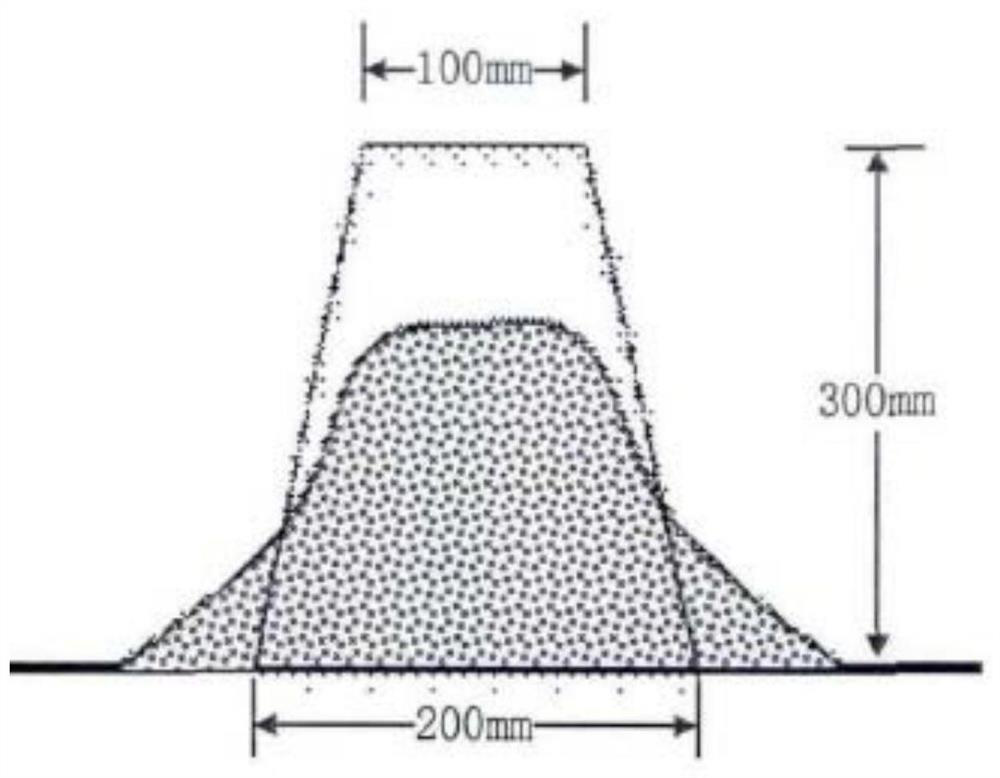

Image

Examples

Embodiment

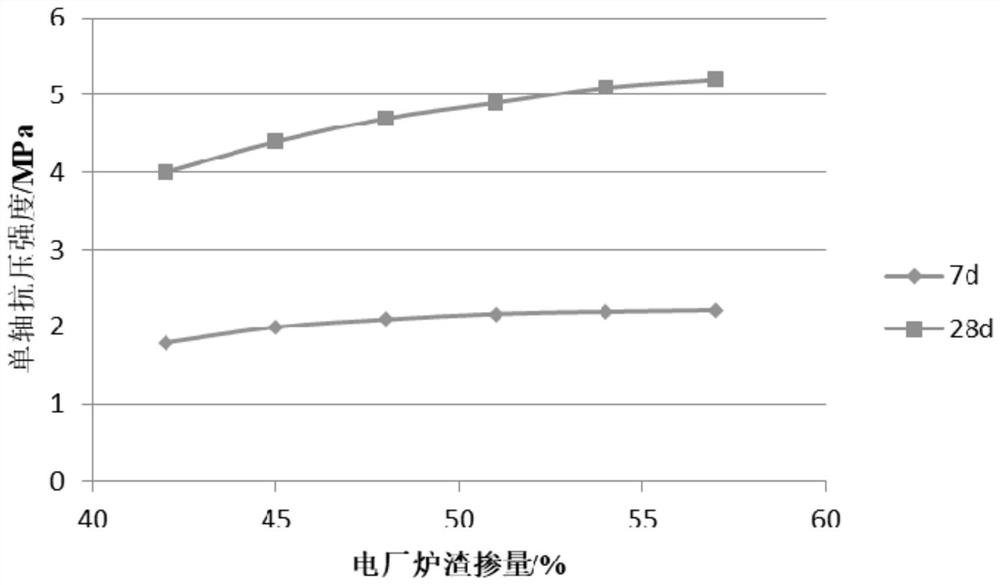

[0043] Filling material mix ratio composition:

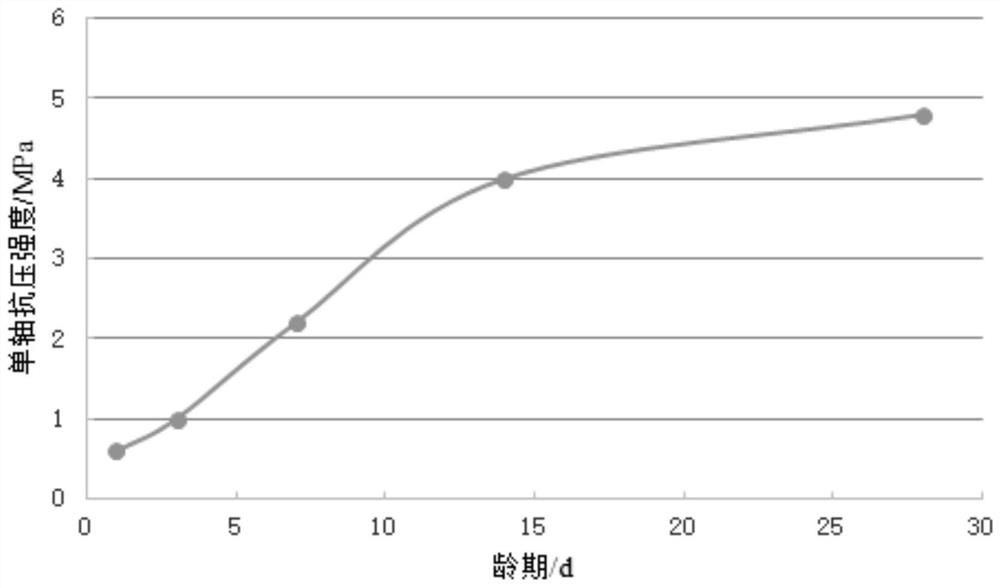

[0044] 1. The strength of paste filling materials increases with age

[0045] In this embodiment, the strength change characteristics of a slag paste with a certain proportion are analyzed. details as follows:

[0046] A kind of paste filling material for mine filling mining, which is composed of the following components by weight percentage: 50.4% slag, 22.7% fly ash, 4.1% cement, 0.1% additive and 22.7% water, wherein, the quick-setting agent is composed of Alumina clinker, sodium carbonate, and quicklime are prepared in a mass ratio of 1:1:0.5.

[0047] Under the condition that the mass concentration of the paste filling material is 77.3%, the variation curves of the uniaxial compressive strength of the slag paste coal mine filling body at different ages are as follows: figure 2 shown. from figure 1 It can be seen that the uniaxial compressive strength of paste filling materials increases with age, and the uniaxial comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com