A kind of Bayer process red mud base filling material and preparation method thereof

A Bayer process red mud and filling material technology, which is applied in the field of Bayer process red mud base filling materials and its preparation, can solve the problems of polluted land and water sources, complicated processes, hidden safety hazards, etc., and achieves high economic value and environmental protection value. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

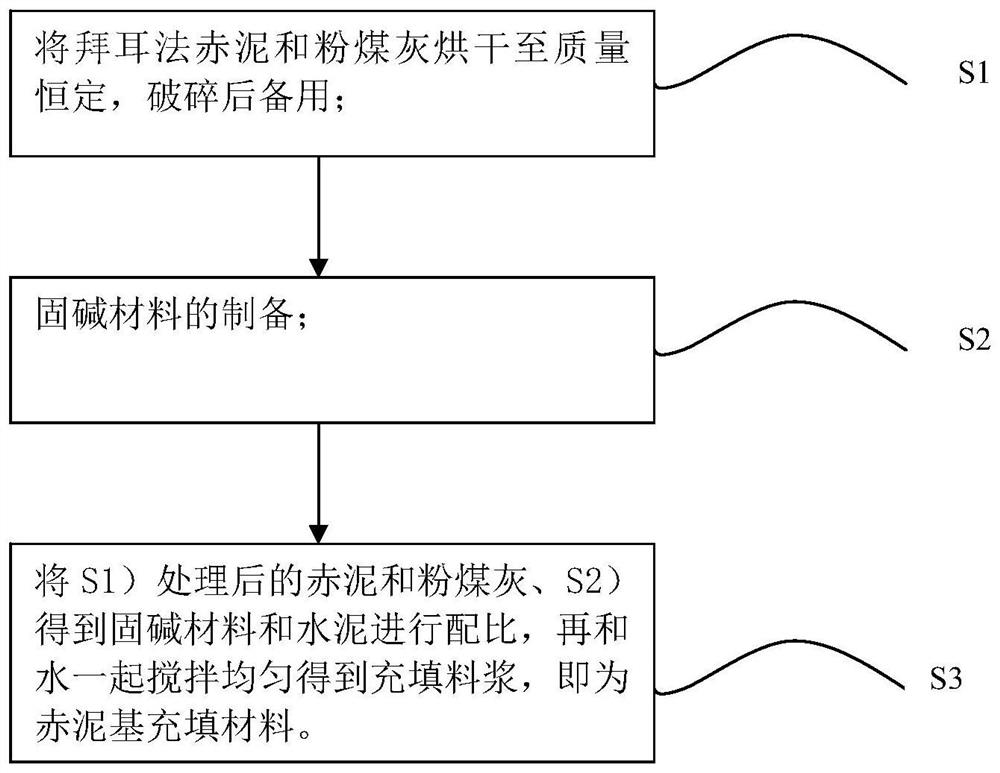

[0034] S2) preparation of solid alkali material;

[0035] S3) The red mud and fly ash after S1) are processed, and S2) is obtained from solid alkali material and cement to obtain solid phase material, and the solid phase material and water are stirred together to obtain filling slurry, which is Bayer red mud-based filling Material.

[0036] The specific steps of said S1) are:

[0037] S1.1) First put the Bayer process red mud in a drying box, dry it at a temperature of 55-70°C until the quality is constant, grind it finely, pass it through a 1.18mm fine sieve, and put it in a moisture-proof bag for later use;

[0038] S1.2) Put the fly ash in a drying box, dry it at a temperature of 55-70°C until the quality is constant, and put it in a moisture-proof bag for later use.

[0039] The specific steps of said S2) are:

[0040] S2.1) First take the inorganic salt, organic acid and neutral mineral admixture by weighing respectively, and mix uniformly to obtain the solid alkali ma...

Embodiment 1

[0047] First dry the Bayer process red mud and fly ash, put them in a moisture-proof bag for later use, and accurately weigh the Bayer process red mud, fly ash, cement and solid alkali materials according to the test ratio of 4:6:0.7:0.3 , among which, the ratio of inorganic salt: organic acid: neutral mineral admixture in the solid alkali material is 1:1:3; then mix Bayer process red mud, fly ash, cement and solid alkali material and pour them into the mortar mixer , and then add water, and the mortar mixer stirs for 4 minutes at a revolution speed of 125±5r / min.

Embodiment 2

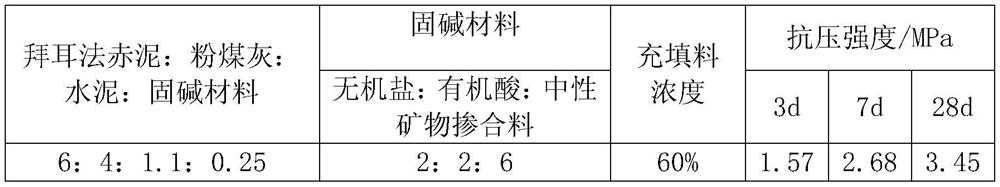

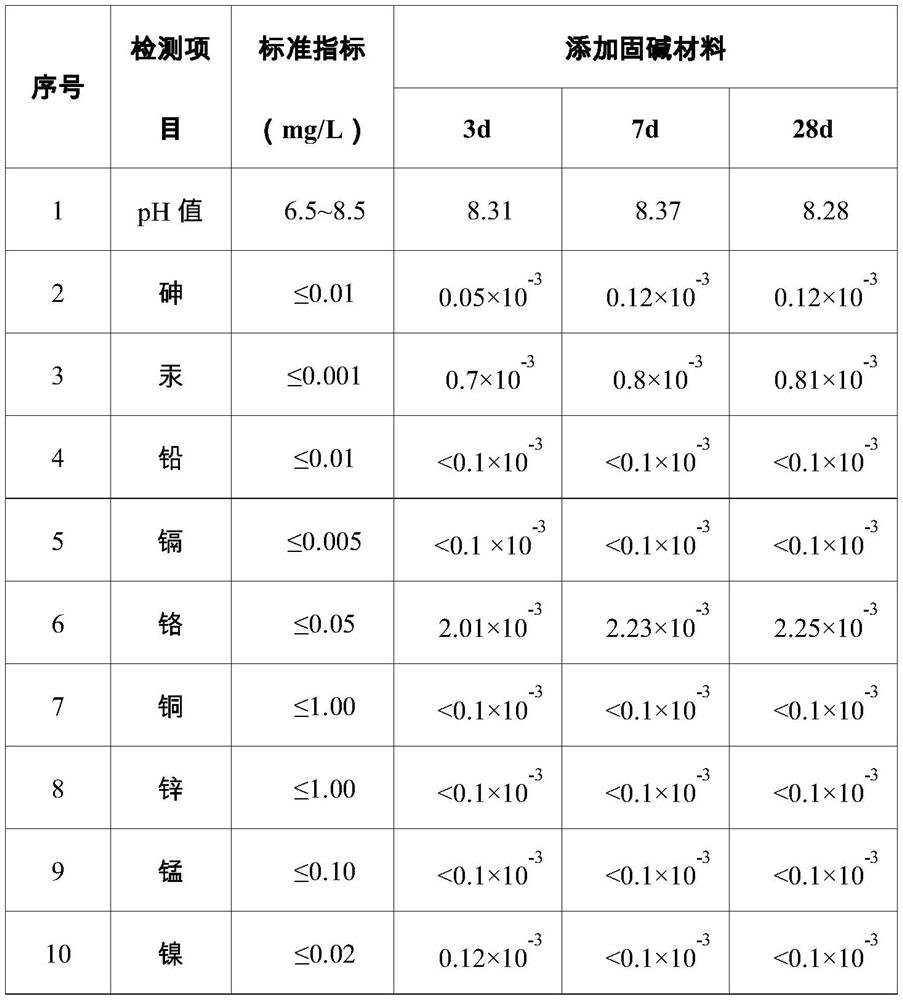

[0049]First dry the Bayer process red mud and fly ash, put them in moisture-proof bags for later use, and accurately weigh the weights of various materials according to the test ratio. The ratio of raw materials is shown in Table 1. Inorganic salts in solid alkali materials: organic Acid: neutral mineral admixture ratio is 2:2:6. First mix the solid phase material evenly and pour it into the plastic sand mixer, then add water, and the plastic sand mixer stirs for 4 minutes at the revolution speed of 125±5r / min. After the stirring is completed, pour the filling material into a standard test mold that is evenly coated with butter, vibrate evenly, and scrape it evenly. After being placed at room temperature for 24 hours, the mold was demoulded, and the test blocks were placed in a standard curing box for 3 days, 7 days, and 28 days, respectively, and the compressive strength of the test blocks at each age was tested. Test the moisture content of the test block that has been cure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com