Filling slurry optimization method for downward layered filling method mining by using waste rock

A technology for filling slurry and filling material, which is applied in the field of filling and mining, and can solve the problem of not comprehensively considering the strength of the filling body and the fluidity and stability of the slurry, low cement content value, and not considering the strength of the cemented filling body and the slurry pipe. The impact of transmission characteristics and other issues can be avoided, and the effect of avoiding the risk of pipe blockage and pipe explosion accidents, as well as great economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] Embodiment: The filling slurry optimization method for the waste rock used in the mining of the downward layered filling method is specifically described as follows.

[0059] 1. The activator ratio optimization of early-strength phosphogypsum-based cementitious materials adopts the following steps:

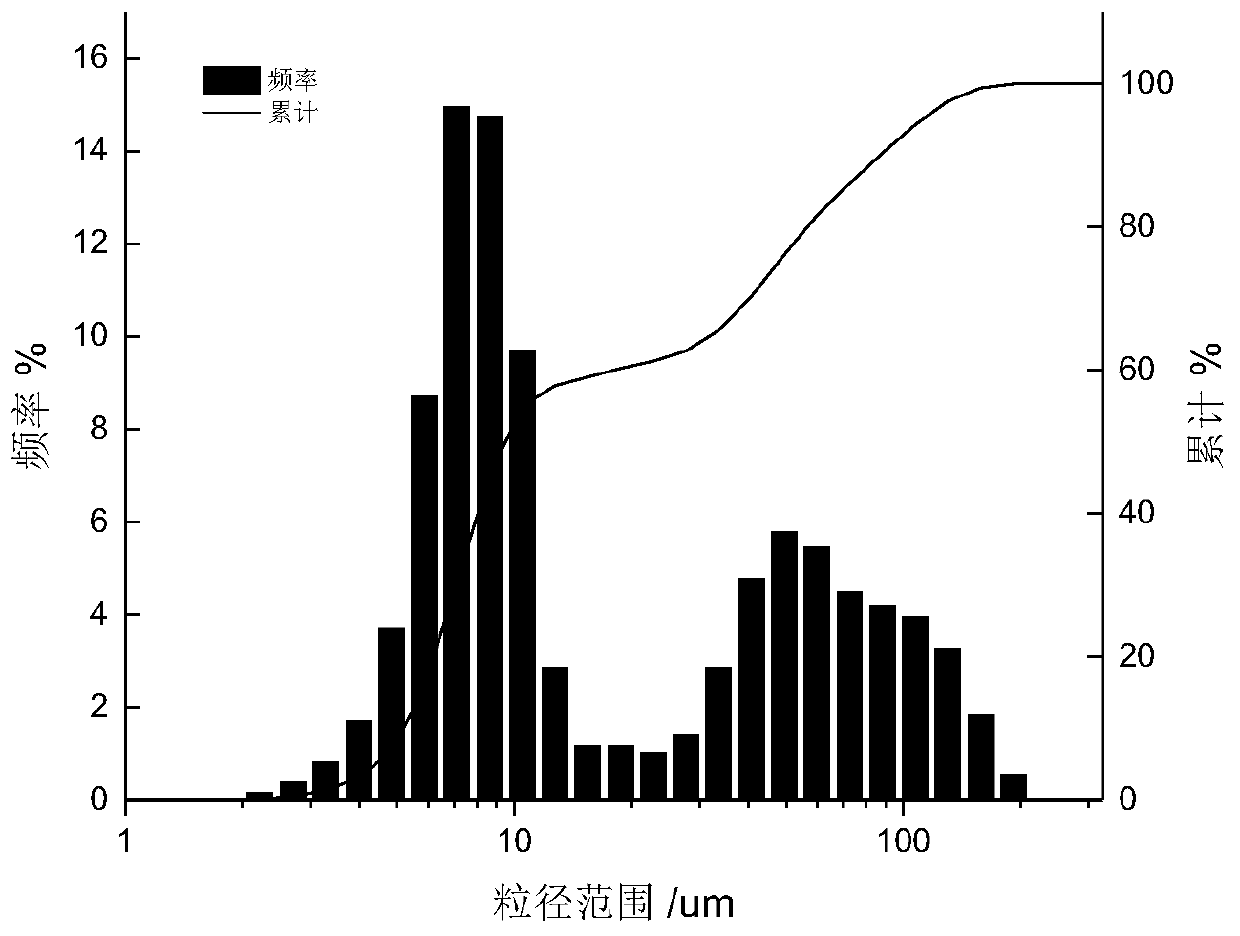

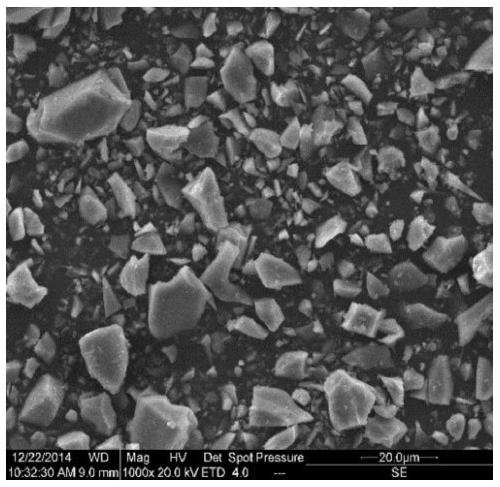

[0060] (1) Dry and grind low-quality phosphogypsum solid waste, and conduct physical and chemical analysis and particle size testing. The results of mineral composition analysis of phosphogypsum are shown in Table 1, and the particle size gradation distribution curve is shown in Table 1. figure 1 , the microscopic surface morphology of phosphogypsum see figure 2 , see the XRD pattern of phosphogypsum image 3 .

[0061] Table 1: Analysis results of mineral composition of phosphogypsum solid waste

[0062]

[0063] (2) Carry out grinding and particle size test to quicklime activator, obtain quicklime particle size distribution characteristic value: d 10 = 2.17 μm, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com