Connected bamboo-UHPC combined bridge deck slab structure adopting grid type bamboo plate

A grid-type and composite bridge technology, which is applied to bridges, bridge parts, bridge materials, etc., can solve the problems of large concrete volume and limit bridge spanning capacity, and achieve the effects of reducing weight, making up for insufficient bending rigidity, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a deeper understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

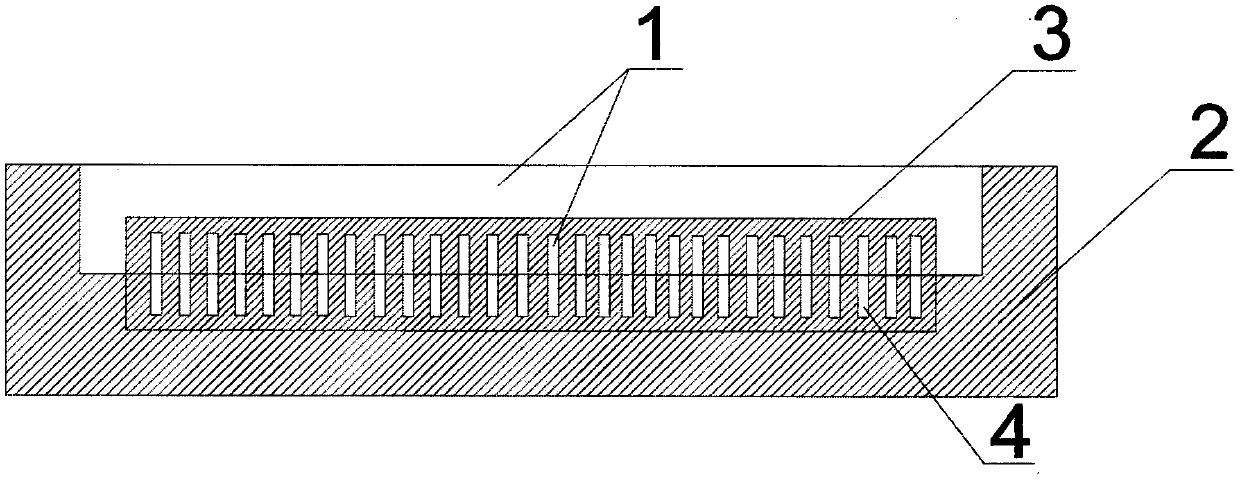

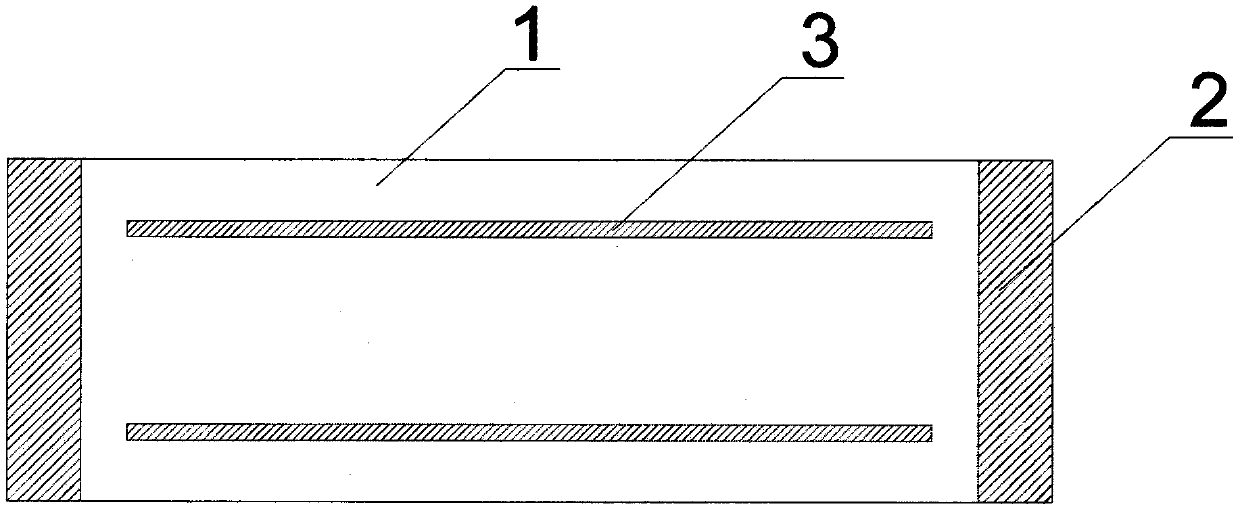

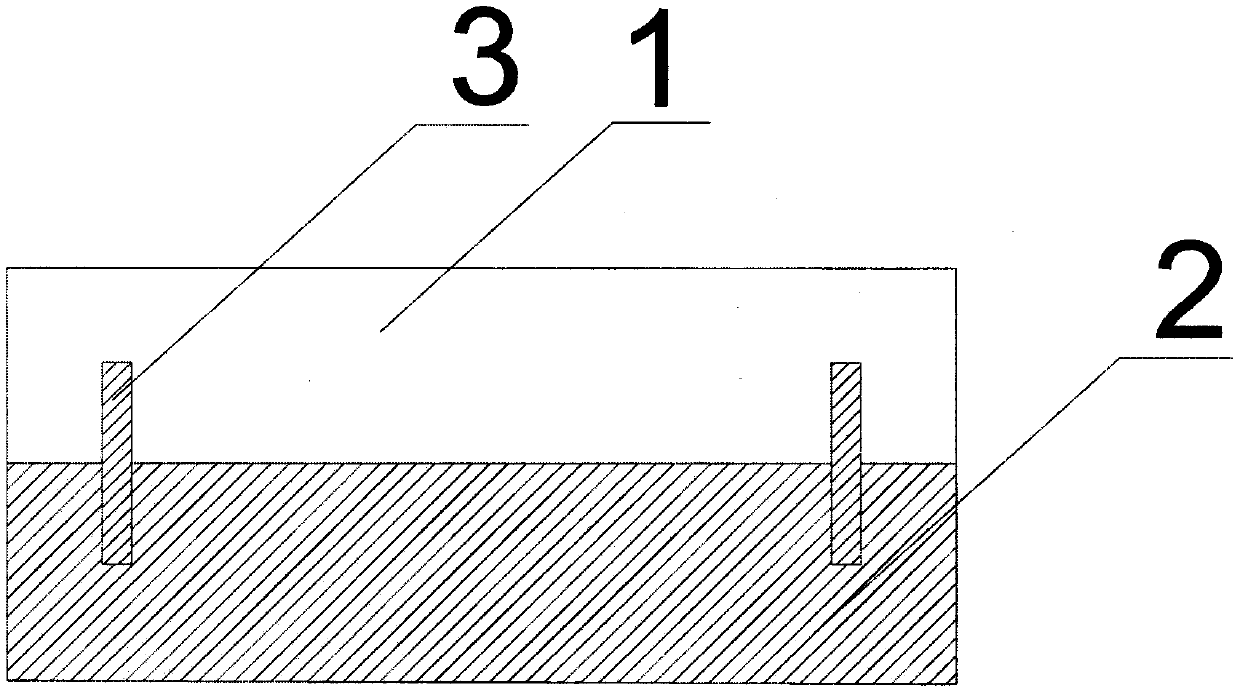

[0018] A composite bridge deck structure that uses grid-type bamboo boards to connect bamboo-UHPC. In the lower layer, cast-in-place UHPC1 in the groove, as the upper layer of the composite bridge deck, make the grid-shaped bamboo board 3 and place it in the middle of the top UHPC1 and the bottom bamboo bridge deck 2, and insert the grid-shaped bamboo board 3 into the bottom bamboo bridge deck 2 as a connector Fill the reserved slot with epoxy resin filler 4. Steel fibers are incorporated into UHPC1, which has sufficient strength and toughness. The bottom bamboo bridge deck 2 and the grid-shaped bamboo board 3 are all made of reconstituted bamboo with excellent tensile properties. The height of the groove is 10cm~15cm, which is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com