Expansion pipe sealing valve and design and manufacturing method thereof

A technology of expansion pipe and sealing valve, applied in the field of new valves, can solve the problems of polluted medium, large valve body, easy wear and failure of valve plate and valve ball, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

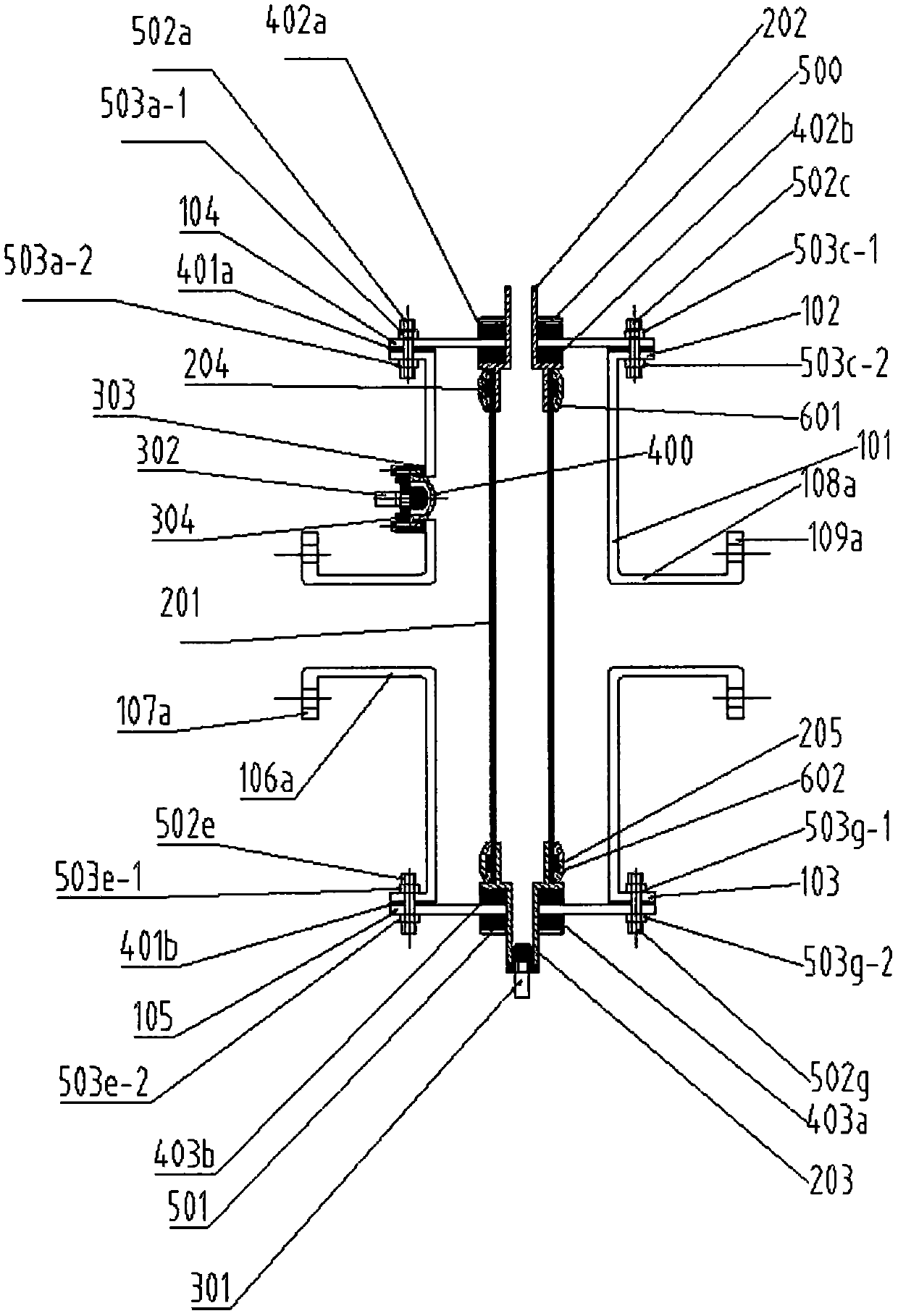

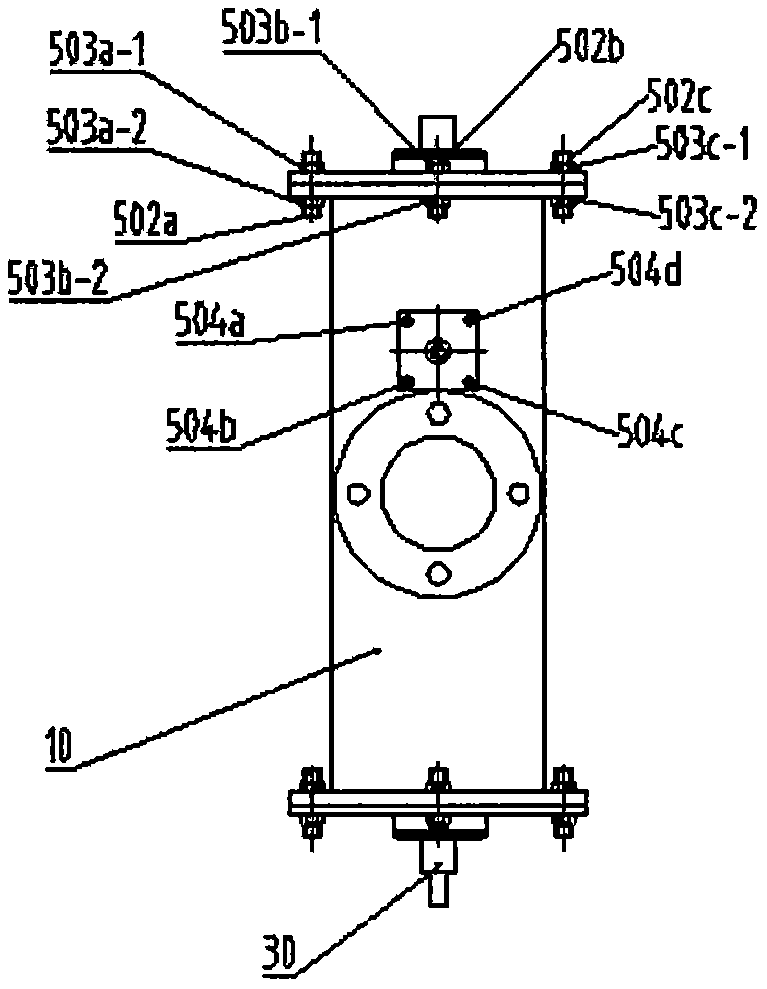

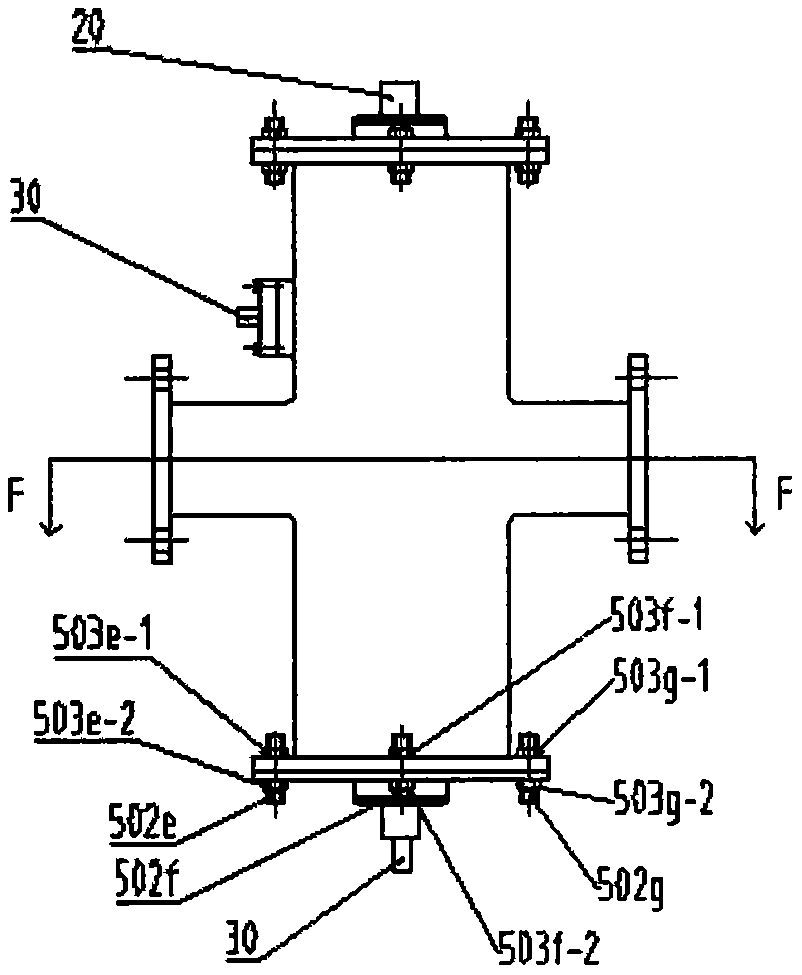

[0140] The technical solution of this solution will be further described in detail below in combination with specific implementation methods.

[0141] exist Figure 1 to Figure 20 Among them, when the aforementioned legend has been marked in detail for spare parts of the same structure, the subsequent legends will mark similar spare parts with component codes instead of all or some of the spare parts in the specific spare part numbers, for example, use (60) component codes to directly mark Upper clamp protection sleeve (601) or lower clamp protection sleeve (602);

[0142] Such as Figure 1 to Figure 20 As shown, the expansion pipe sealing valve provided by this scheme includes:

[0143] valve body assembly (10); expansion tube assembly (20); open position and close position sensor assembly (30); sealing assembly (40); connection assembly (50); protection assembly (60);

[0144] Among them, the valve body assembly (10)

[0145] Valve body (101); valve body upper flange (10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com