Wire terminal riveting and detecting all-in-one machine and using method thereof

An all-in-one machine and terminal technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, circuits, electrical components, etc., can solve the problem of insufficient connection strength between terminals and wires, and achieve the effect of improving the degree of connection and the firmness of the connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

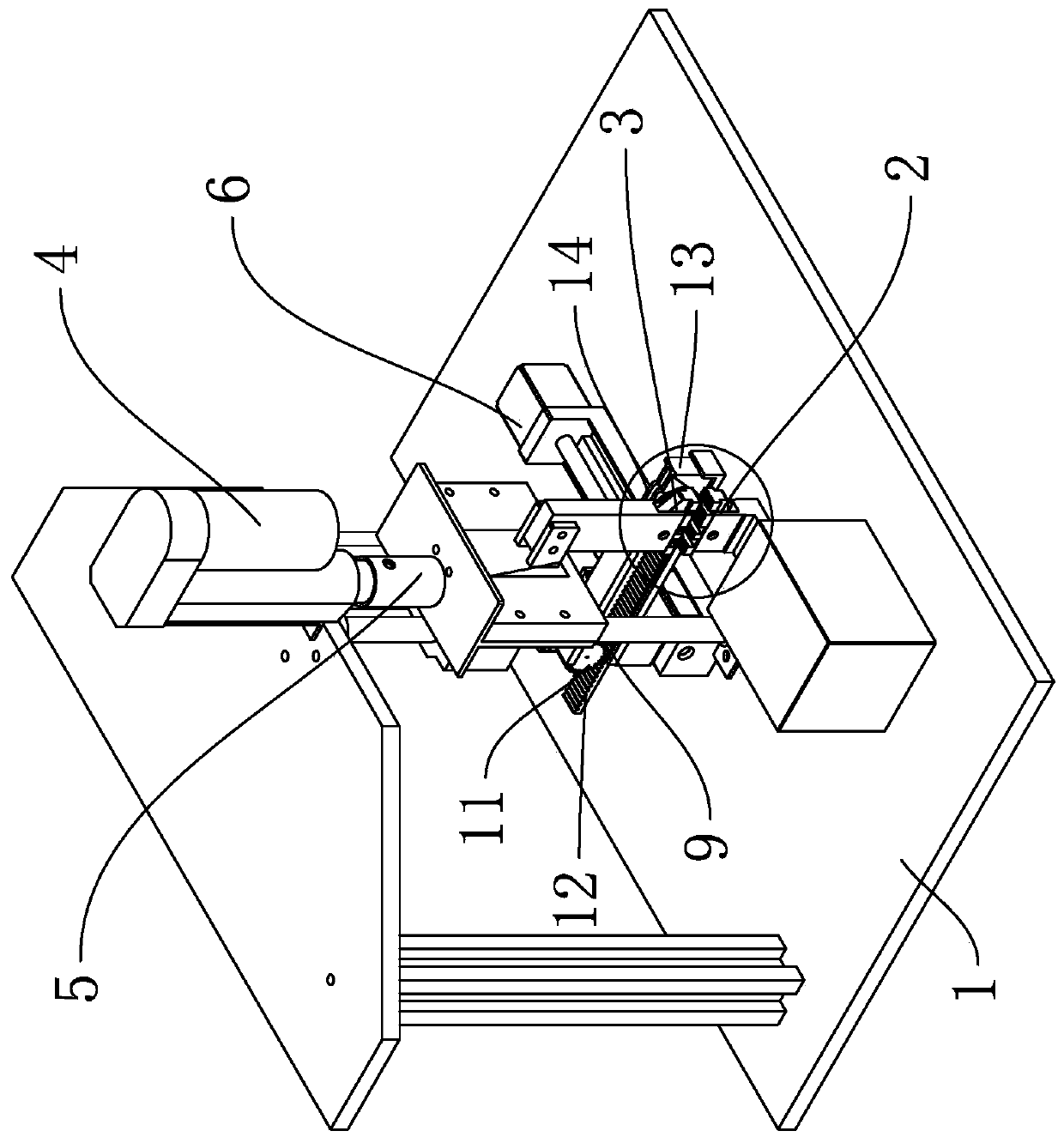

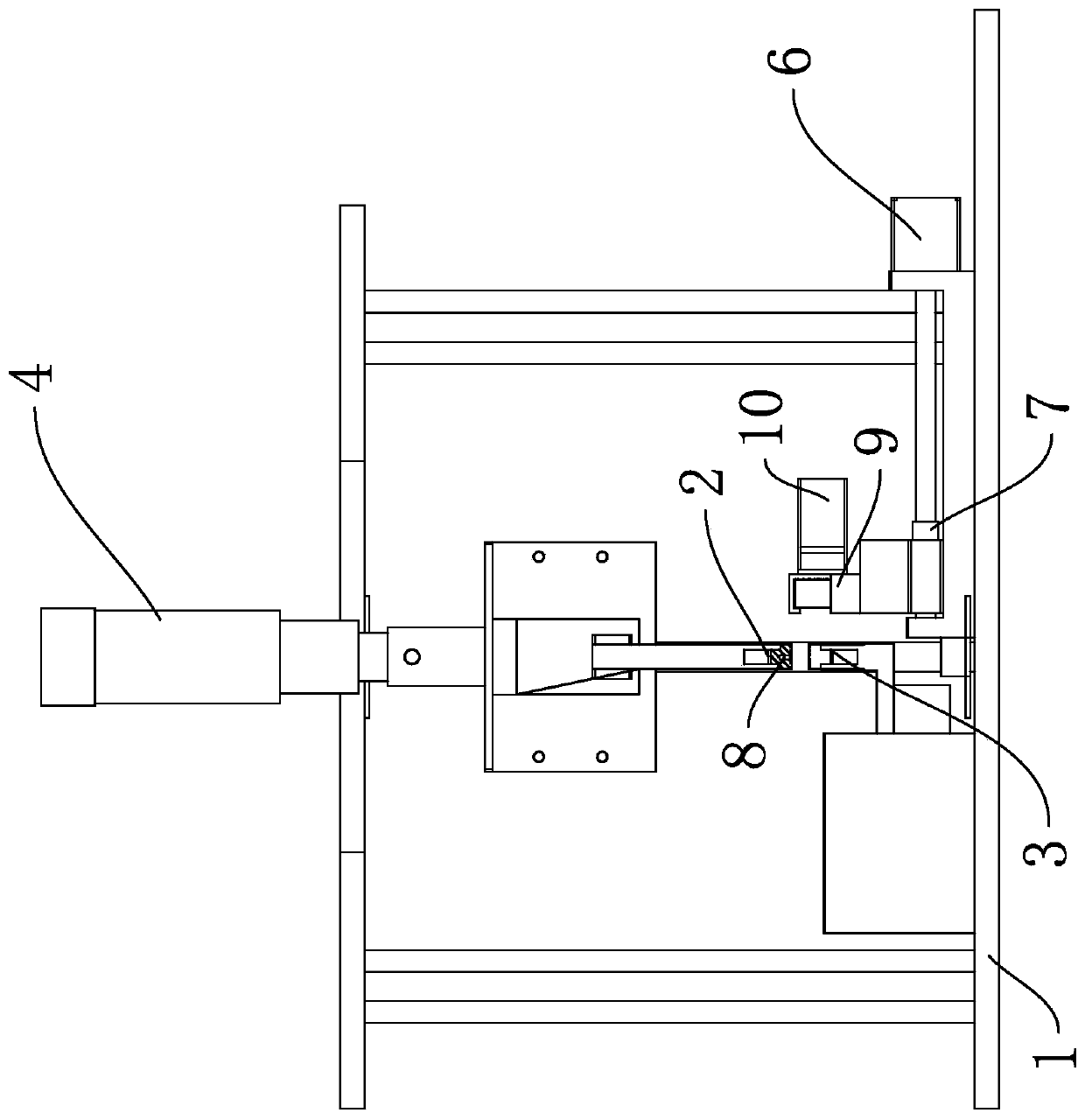

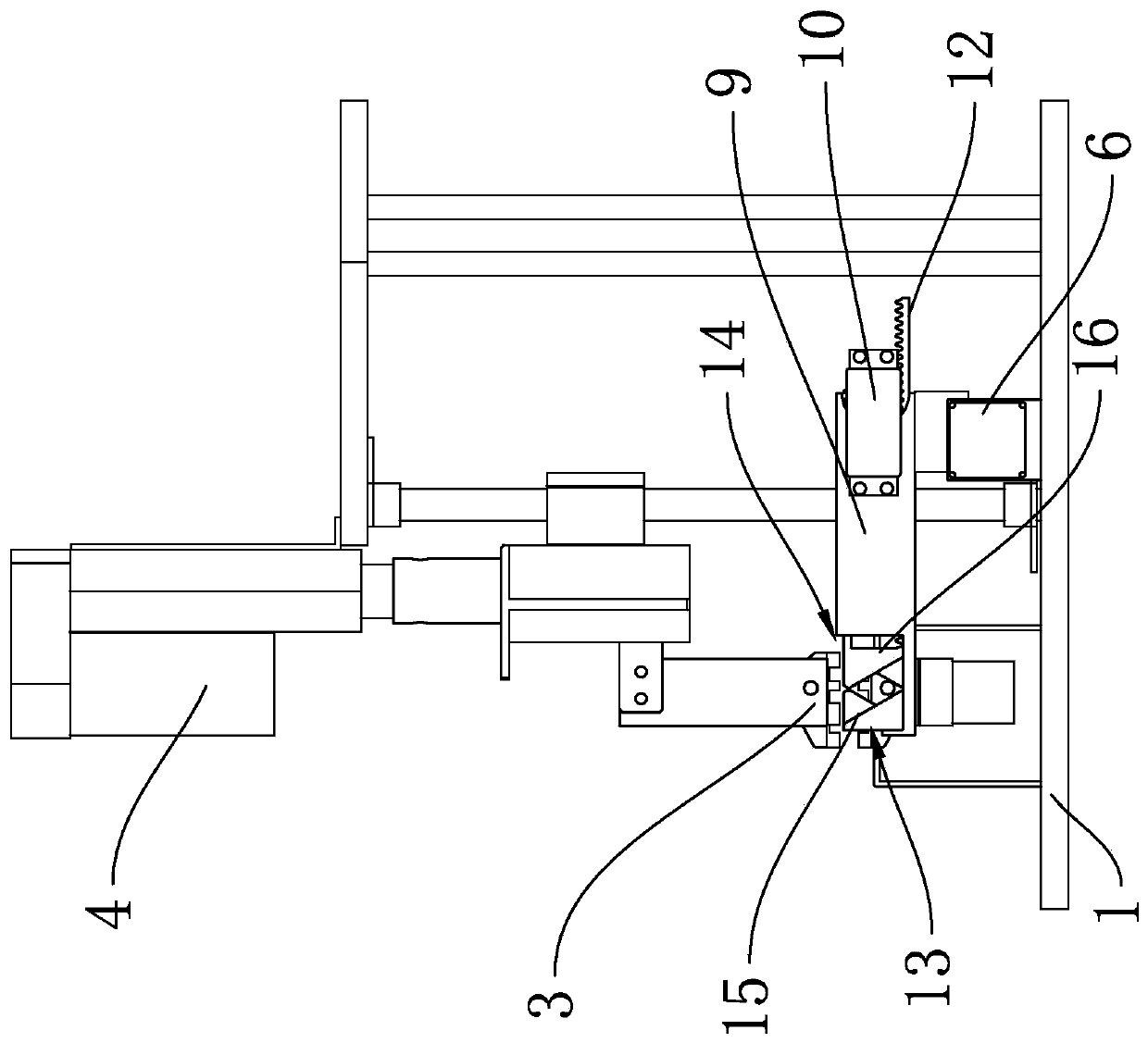

[0044] Such as Figure 1 to Figure 6 As shown, the all-in-one machine for riveting and crimping detection of wire terminals includes a base 1, a lower pressing film 2, an upper pressing film 3, a fixing assembly, a first driving part 4, a pressure sensor 5, a second driving part 6 and a tension sensor 7. There are several lower extrusion grooves 2a with different widths and parallel to each other on the film 2, and several lower accommodation grooves 2b perpendicular to the lower extrusion grooves 2a are provided on the upper surface of the lower pressure film 2; 2 moving up and down, the upper pressing film 3 has an upper extrusion groove 3a corresponding to the lower extrusion groove 2a and an upper accommodation groove ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap