Pulling platform for heading vegetable

A vegetable and balling technology, applied in the field of agricultural machinery, can solve the problems of large power consumption, high manufacturing cost and narrow import range, and achieve the effects of less power consumption, low manufacturing cost and wide import range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

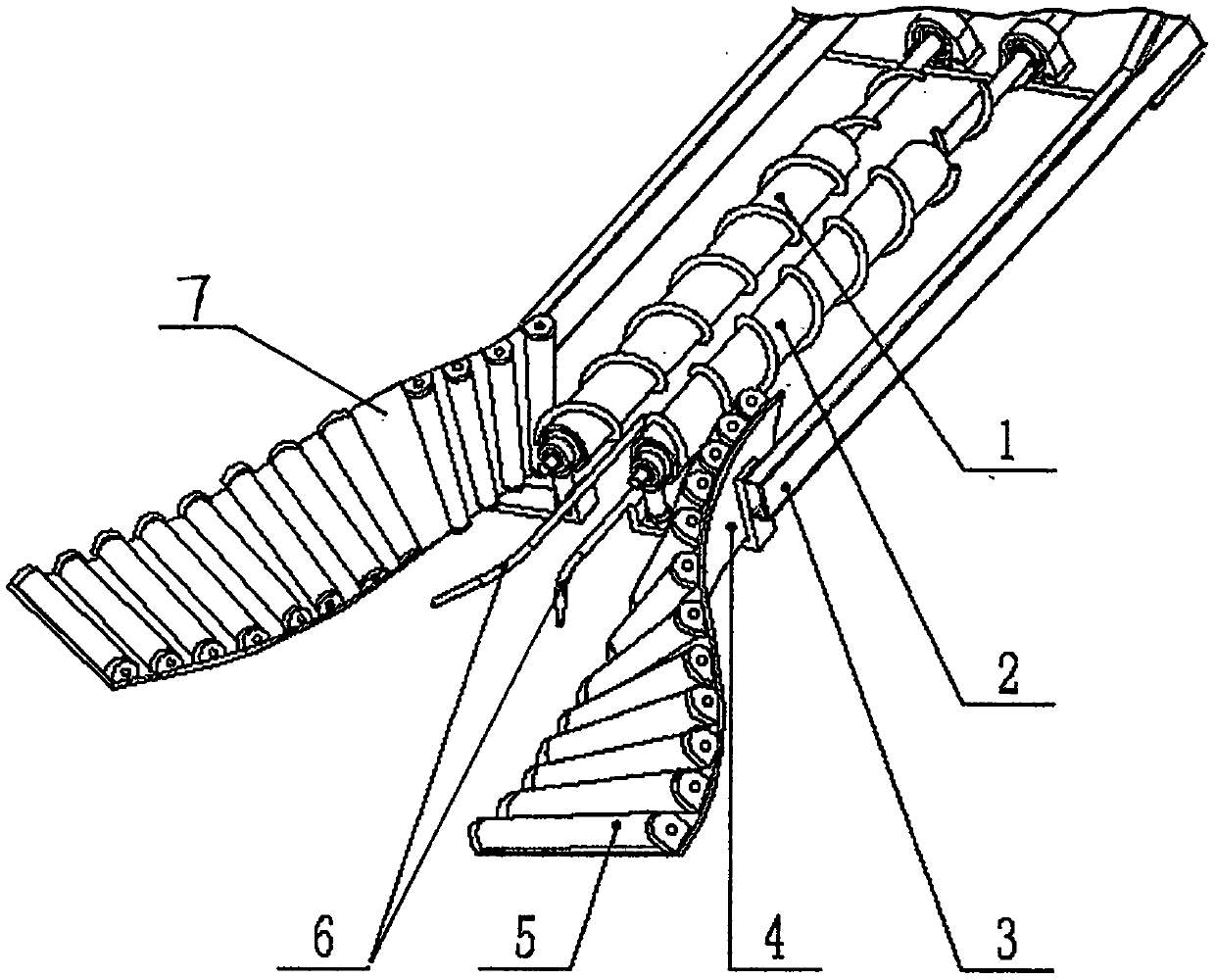

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A kind of table for pulling vegetables with balls includes a platform 3, on the middle part of the platform 3, parallel to each other and rotatable, equipped with a right helical shaft 1 and a left helical shaft 2, on the platform 3. On the front end of the center, the root guide arc-shaped fork group 6 is installed at the front part of the right screw shaft 1 for pulling up and the left screw shaft 2 for pulling up. On the left and right sides of the front end of the stand 3, it is located The screw shaft 2, the root leading into the left outer front part of the arc-shaped fork group 6, and the left righting leading-in twisting plate 4 are respectively installed symmetrically at the right outer front part of the lifting right screw shaft 1 and the root leading into the arc-shaped fork group 6 And right righting imports twisted plate 7, on the relative i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com