Rotating disk type milking robot

A robot and turntable technology, applied in the direction of milk container, milking device, dairy products, etc., can solve the problems that milk hygiene cannot be well controlled, milk pollution, and milk hygiene cannot be effectively controlled, etc., to achieve The effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

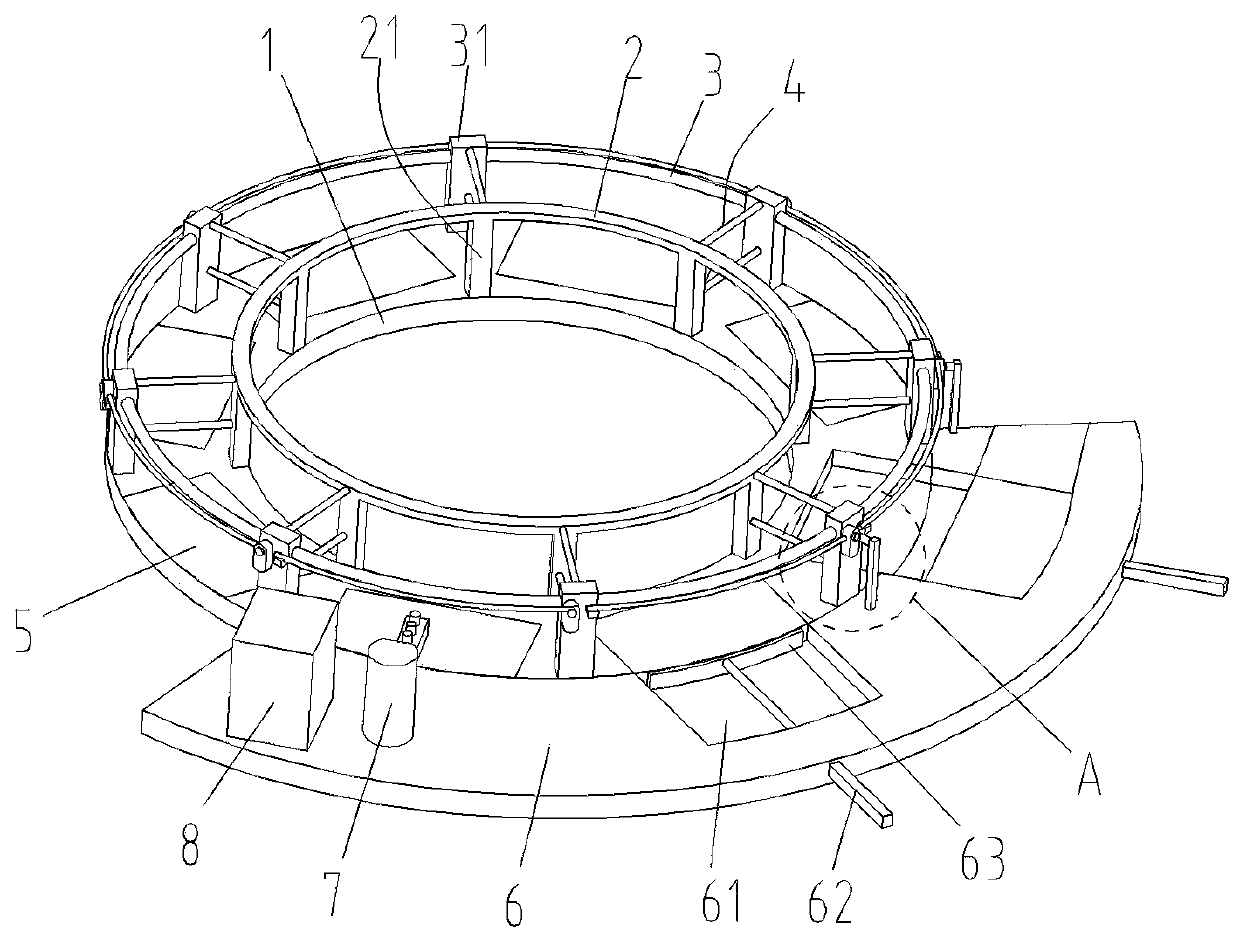

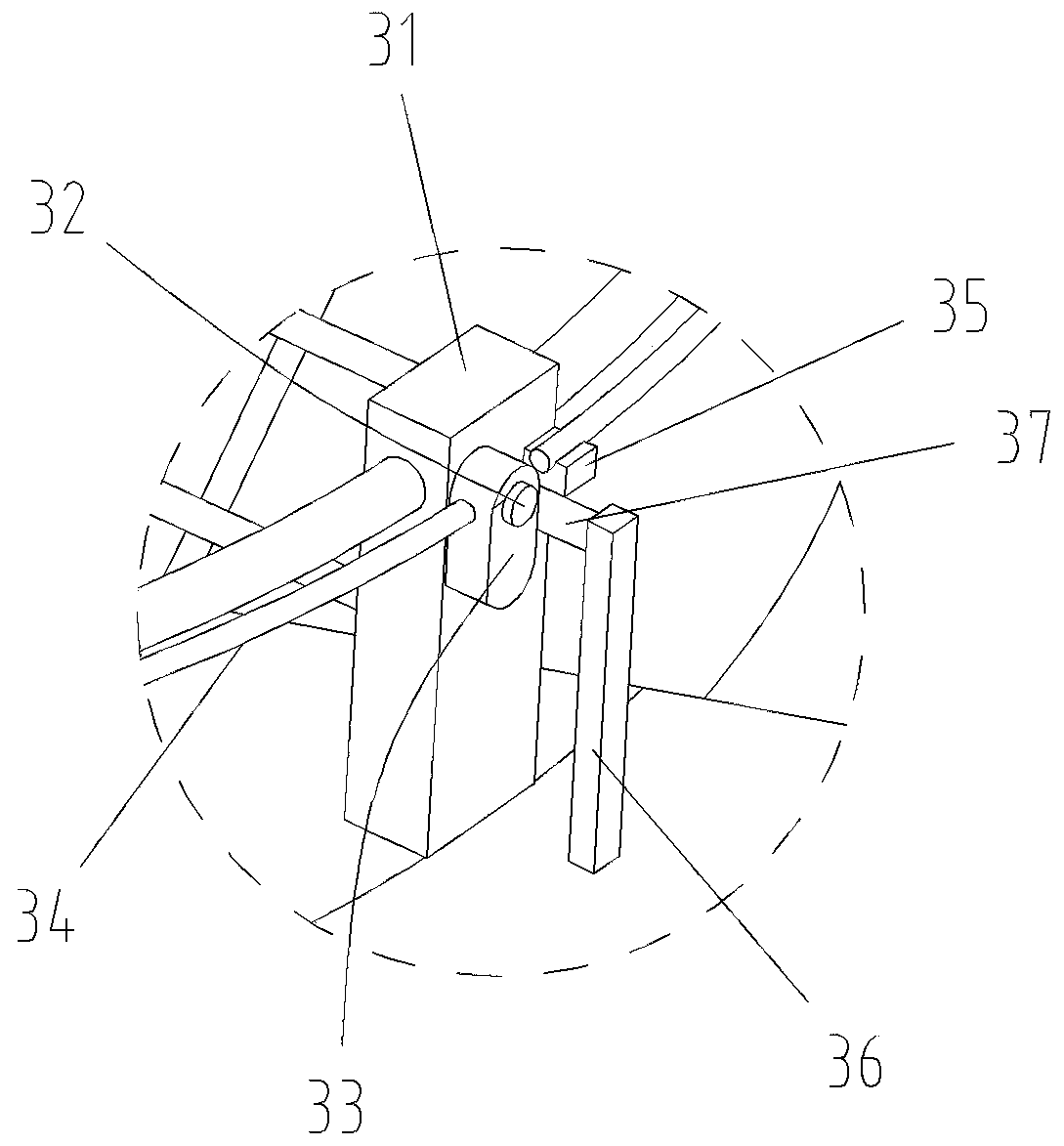

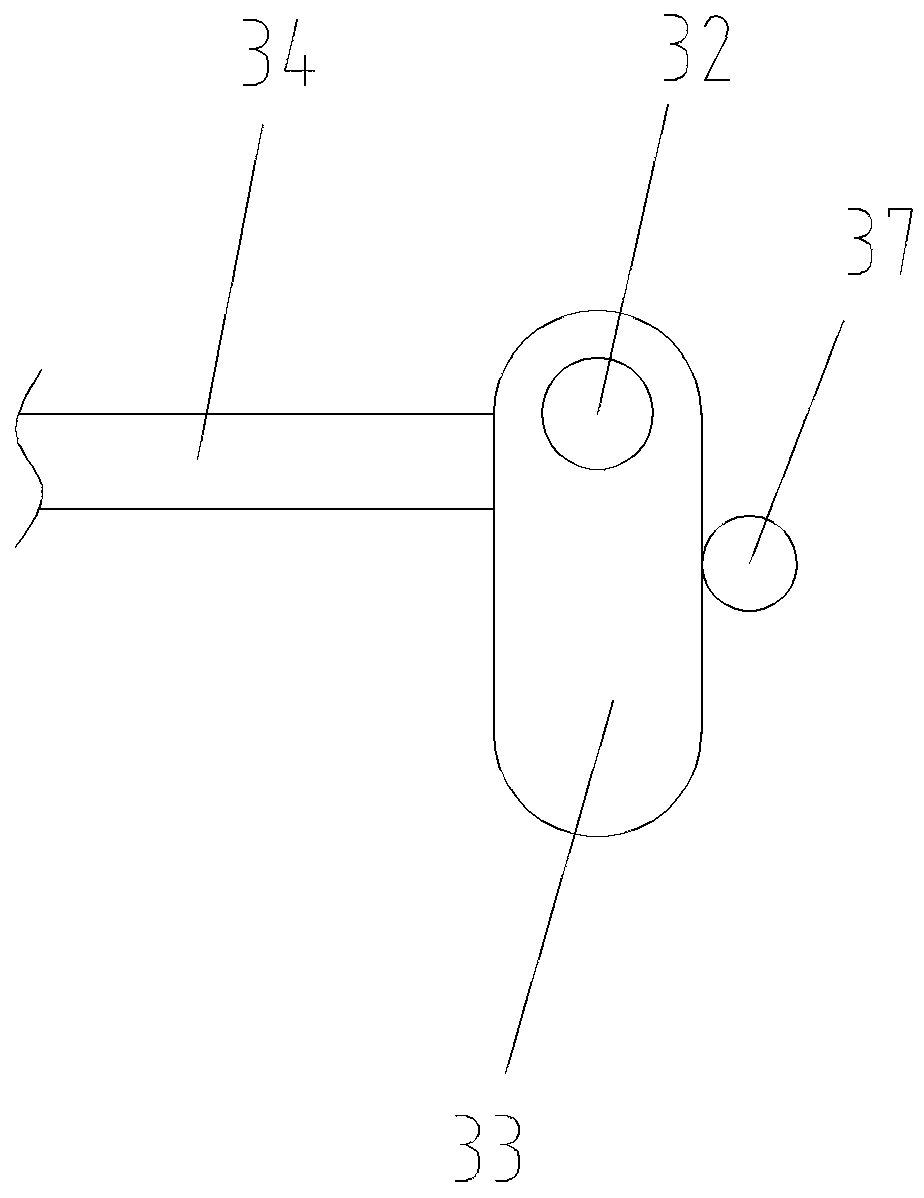

[0029] Such as Figure 1-9 As shown, the turntable milking robot provided by the present invention includes a turntable device, one side of the turntable device is provided with a working plate 6, and the working plate 6 is provided with a milking device 7 and a storage box 8 for storing milk.

[0030] The milking device 7 includes a mechanical arm fixed on the upper side of the working plate 6. The mechanical arm is a prior art. The mechanical arm in this embodiment adopts HR12-C4 industrial robot, and the connecting rod is fixedly connected at the end of the mechanical arm. 71, the connecting rod 71 is away from the mechanical arm and is fixedly connected to the installation box 72. Four recognition cameras 75 are evenly equipped on one side of the installation box 72. The recognition camera 75 is a prior art, and the recognition camera 75 adopts a binocular stereo camera. The lower side of the 72 is fixedly connected to the working box 73, and the first dividing plate 731 v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com