Filter stick without outer wrapping paper and with continuous closed cavities, forming equipment and forming process

A technology of closed cavity and molding process, which is applied in the fields of e-liquid filter elements, applications, tobacco, etc., can solve the problems of multiple production processes and high production costs, and achieve the effects of broad application prospects, reduced loss, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

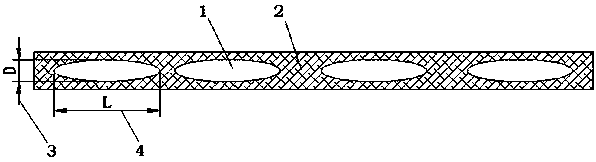

[0034] Such as figure 1 The non-wrapping paper filter rod with continuous closed cavities shown uses acetate fiber and thermosetting adhesive as the main raw materials, and has a structure of four closed cavities arranged continuously along the axis line inside the filter rod and independent of each other;

[0035] The axial length of the cavity is greater than the radial length, and the radial dimension is about 1 / 3-2 / 3 of the diameter of the filter rod.

[0036] The diameter D of each cavity ranges from 3 to 5 mm, and the length L ranges from 10 to 15 mm.

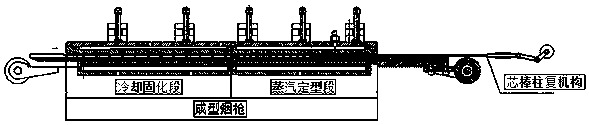

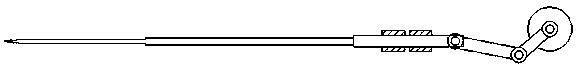

[0037] Such as figure 2 The filter rod forming equipment shown has a forming mandrel, a driving mechanism that controls the reciprocating advance and retreat of the forming mandrel, and a forming pipe; the inside of the forming pipe is a filter rod forming cavity, and the forming mandrel enters from the entrance of the tow during use The forming cavity, the part entering the forming cavity can reciprocate in the formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com