In-situ synthesis mixed phase reinforced magnesium-based amorphous composite material based on selective phase dissolution and preparation method thereof

An amorphous composite material and a composite material technology are applied in the field of in-situ hybrid phase reinforced magnesium-based amorphous composite material and its preparation, which can solve the problem that the mechanical properties such as the strong plasticity of the composite material are difficult to improve, and the second phase is difficult to uniformly disperse and distribute. and other problems, to achieve the effects of large plastic deformation, improved mechanical properties, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the in-situ self-generated hybrid phase-reinforced magnesium-based amorphous composite material based on selective phase dissolution provided by the present invention comprises the following steps:

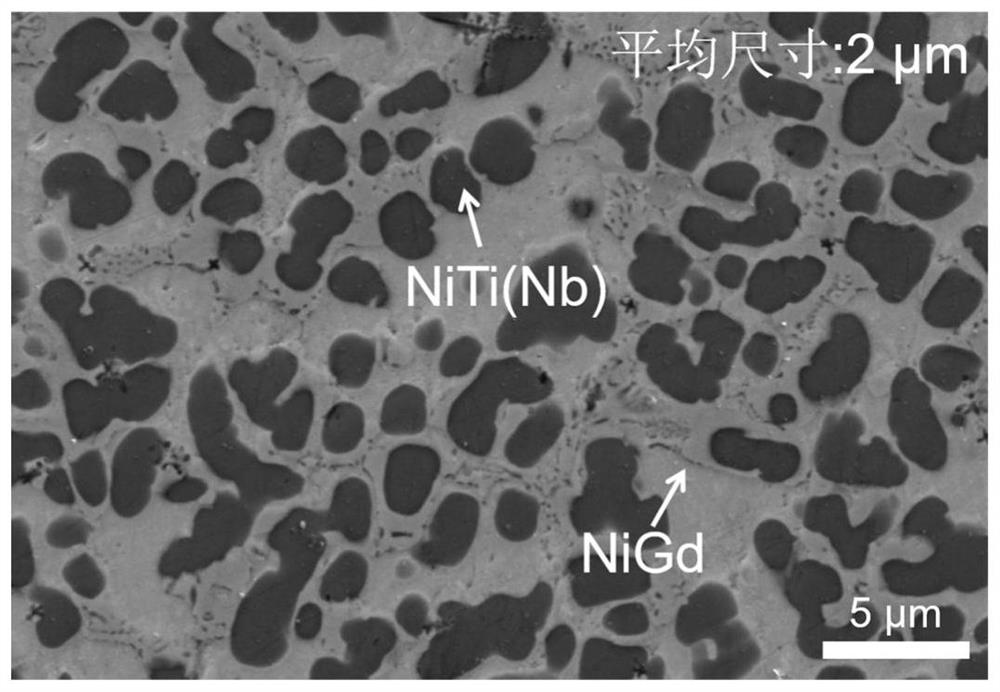

[0036] S1, Ni, Ti, Gd, Nb raw materials are mixed and smelted, and the Ni-Ti-Gd-Nb pre-alloy with NiTi (Nb) and NiGd two phases is obtained after cooling;

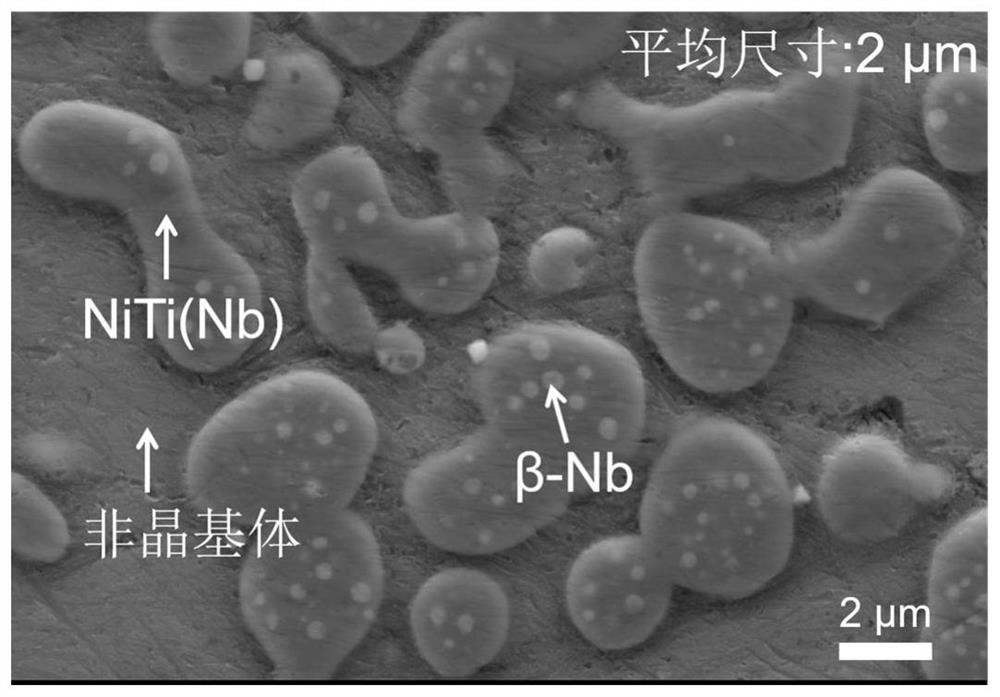

[0037] S2, annealing the Ni-Ti-Gd-Nb pre-alloy, so that the nano-β-Nb phase is precipitated from the NiTi(Nb) phase, and a hybrid reinforced structure is obtained;

[0038] S3. Mix and smelt the annealed Ni-Ti-Gd-Nb pre-alloy with Mg and Ag raw materials. After cooling, the matrix is Mg-Ni-Gd-Ag amorphous alloy, NiTi(Nb)+β-Nb mixed The magnesium-based amorphous composite material is dispersedly distributed in the matrix.

[0039] The invention adopts a novel selective phase dissolution process, supplemented by subsequent annealing treatment, and successfully introduces the in-situ self-gener...

Embodiment 1

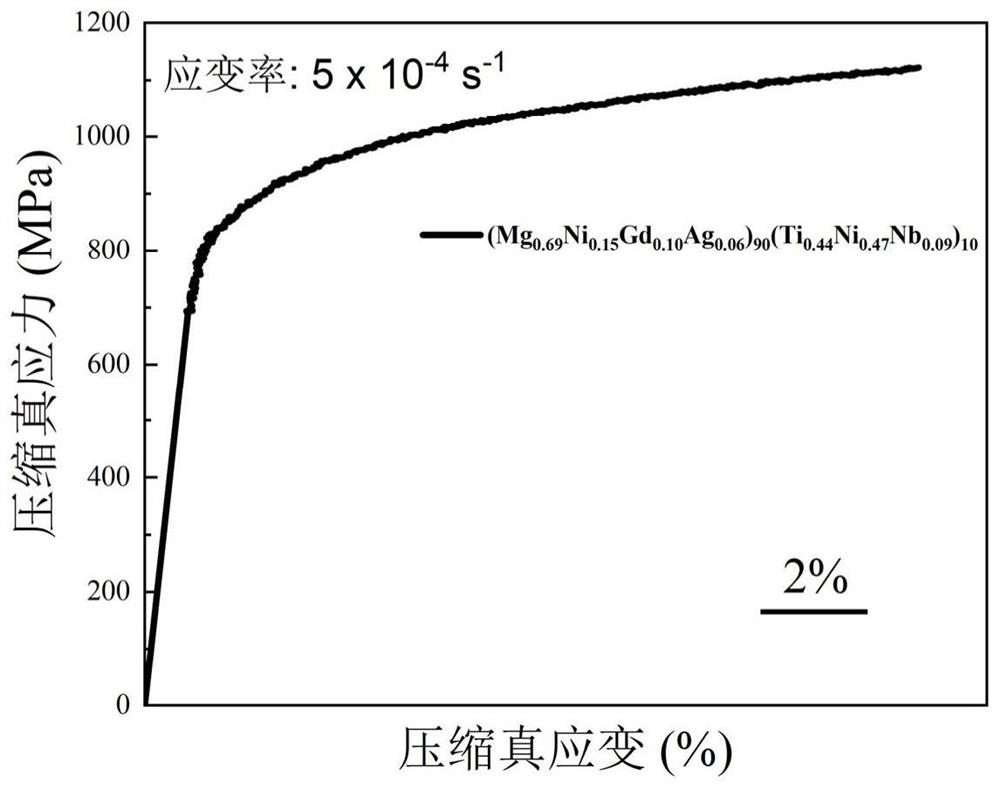

[0060] 1) Grind the nickel block, titanium block, gadolinium block, niobium block, and magnesium block with a purity of 99.9% to remove the surface scale, and then perform ultrasonic cleaning in absolute ethanol. After drying, follow the (Mg 0.69 Ni 0.15 Gd 0.10 Ag 0.06 ) 90 (Ti 0.44 Ni 0.47 Nb 0.09 ) 10 Atomic formulation of nickel block, titanium block, gadolinium block, niobium block;

[0061] 2) Put the prepared raw materials of nickel block, titanium block, gadolinium block and niobium block into the vacuum arc melting furnace, and vacuumize to 3×10 - 3 After Pa, argon gas is passed into the vacuum chamber until the chamber pressure is -0.05MPa; the raw materials are arc smelted, and the alloy ingots at each station are kept for 3 minutes after they are completely melted. Remelting after turning over, each alloy ingot was smelted 4 times in total, after smelting, it was cooled with a water-cooled copper mold, and the initial Ni-Ti-Gd-Nb alloy ingot was taken out;...

Embodiment 2

[0070] 1) Grind the nickel block, titanium block, gadolinium block, niobium block, and magnesium block with a purity of 99.9% to remove the surface scale, and then perform ultrasonic cleaning in absolute ethanol. After drying, follow the (Mg 0.69 Ni 0.15 Gd 0.10 Ag 0.06 ) 95 (Ti 0.44 Ni 0.47 Nb 0.09 ) 5 Atomic formulation of nickel block, titanium block, gadolinium block, niobium block;

[0071] 2) Put the prepared raw materials of nickel block, titanium block, gadolinium block and niobium block into the vacuum arc melting furnace, and vacuumize to 3×10 - 3 After Pa, pass argon gas into the vacuum chamber until the chamber pressure is -0.05MPa; carry out arc melting on the raw materials, and keep the raw materials for 3 minutes after they are completely melted. Smelting 4 times, after the smelting is finished, the bottom mold in the electric arc melting furnace, namely the water-cooled copper mold, is cooled, and the initial Ni-Ti-Gd-Nb alloy ingot is taken out;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| fracture strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com