Anti-explosion foam spray fire extinguishing system

A fire-extinguishing system and foam technology are applied in the field of anti-explosion foam spray fire-extinguishing systems, which can solve problems such as deformation, explosion, and wastage of fire-fighting branch pipes, and achieve the effects of improving the reliability of use, solving the technical problems of fire fighting, and being convenient for installation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

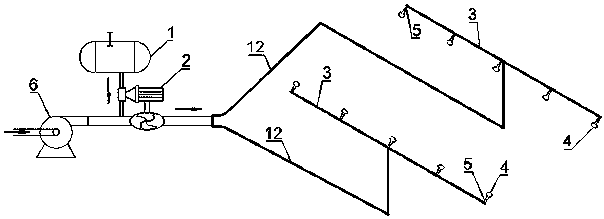

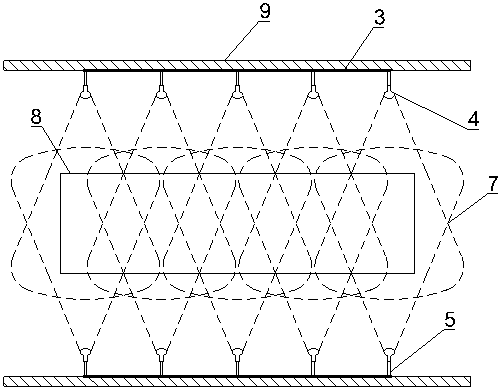

[0029] Such as Figure 1 to Figure 6 As shown, the anti-explosion foam spray fire extinguishing system includes a fire pump set 6, a liquid storage tank 1, a foam proportional mixer 2, a liquid supply pipe network 12, a horizontal pipeline 3, a pressure expansion tube 5, a water mist nozzle 4, and a fire pump set 6. The inlet is connected to the fire water source. The fire pump group 6 is connected to the inlet of the liquid supply pipe network 12 through the foam proportional mixer 2. The outlet of the liquid supply pipe network 12 is respectively connected to several horizontal pipes 3. Each horizontal pipe 3 is equipped with several The pressure expansion tube 5 of the water mist nozzle 4; the foam proportional mixer 2 communicates with the liquid storage tank 1.

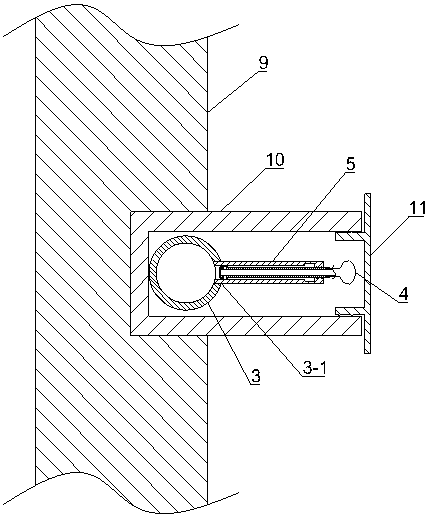

[0030] One end of the pressure telescopic tube 5 is connected to the horizontal pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com