Powder collecting system

A collection system and powder technology, applied in the direction of solid separation, magnetic separation, measuring devices, etc., can solve the problems of single and frequent air flow channels, powder blockage, etc., to extend the service life, improve production efficiency, and reduce inner cavity blockage The effect of probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

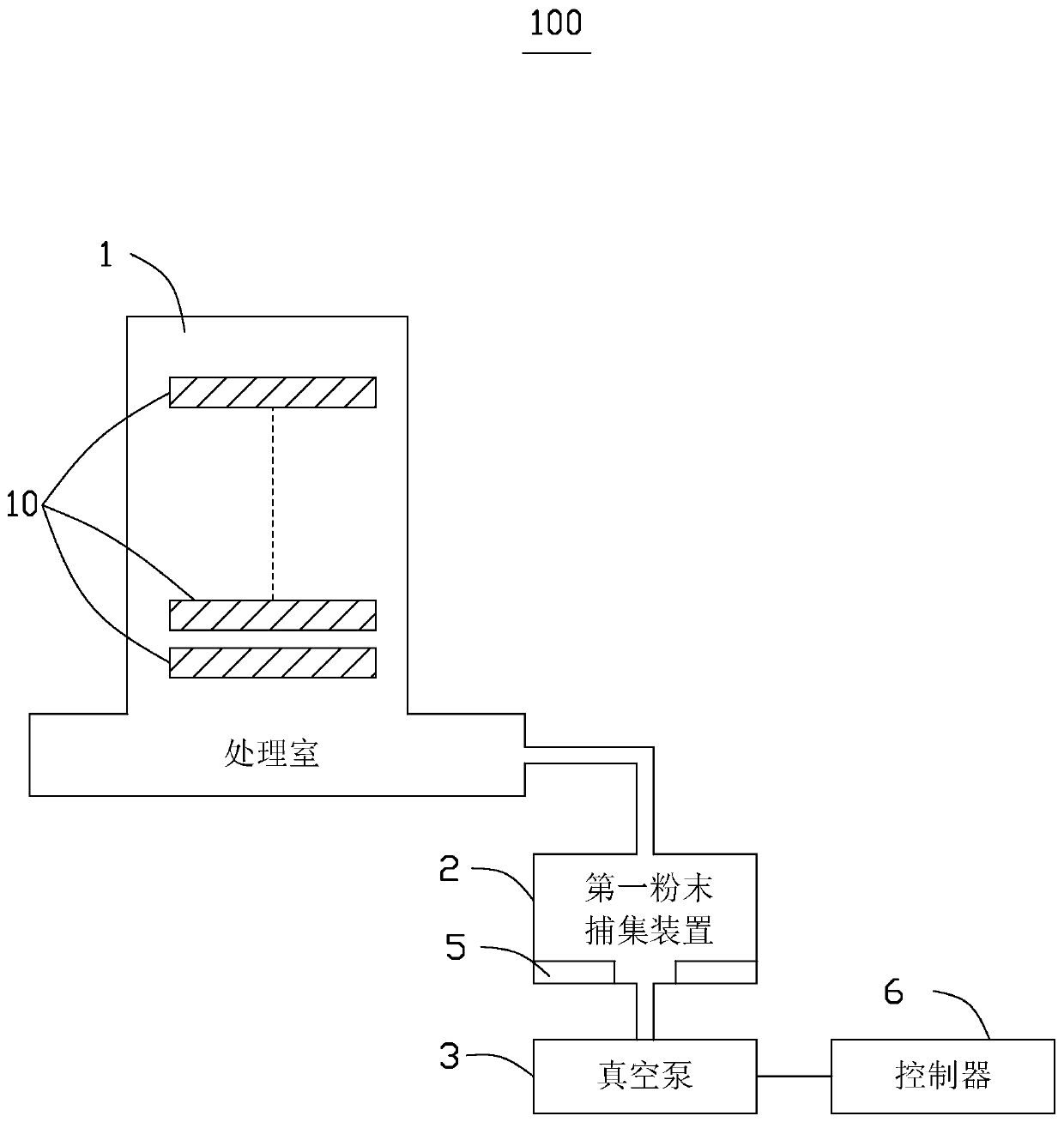

[0029] see figure 1 and figure 2 , In one embodiment, the powder collection system 100 includes a processing chamber 1 , a first powder collection device 2 and a vacuum pump 3 . At least one semiconductor wafer 10 is placed in the processing chamber 1 , and the first powder collection device 2 is connected between the processing chamber 1 and the vacuum pump 3 .

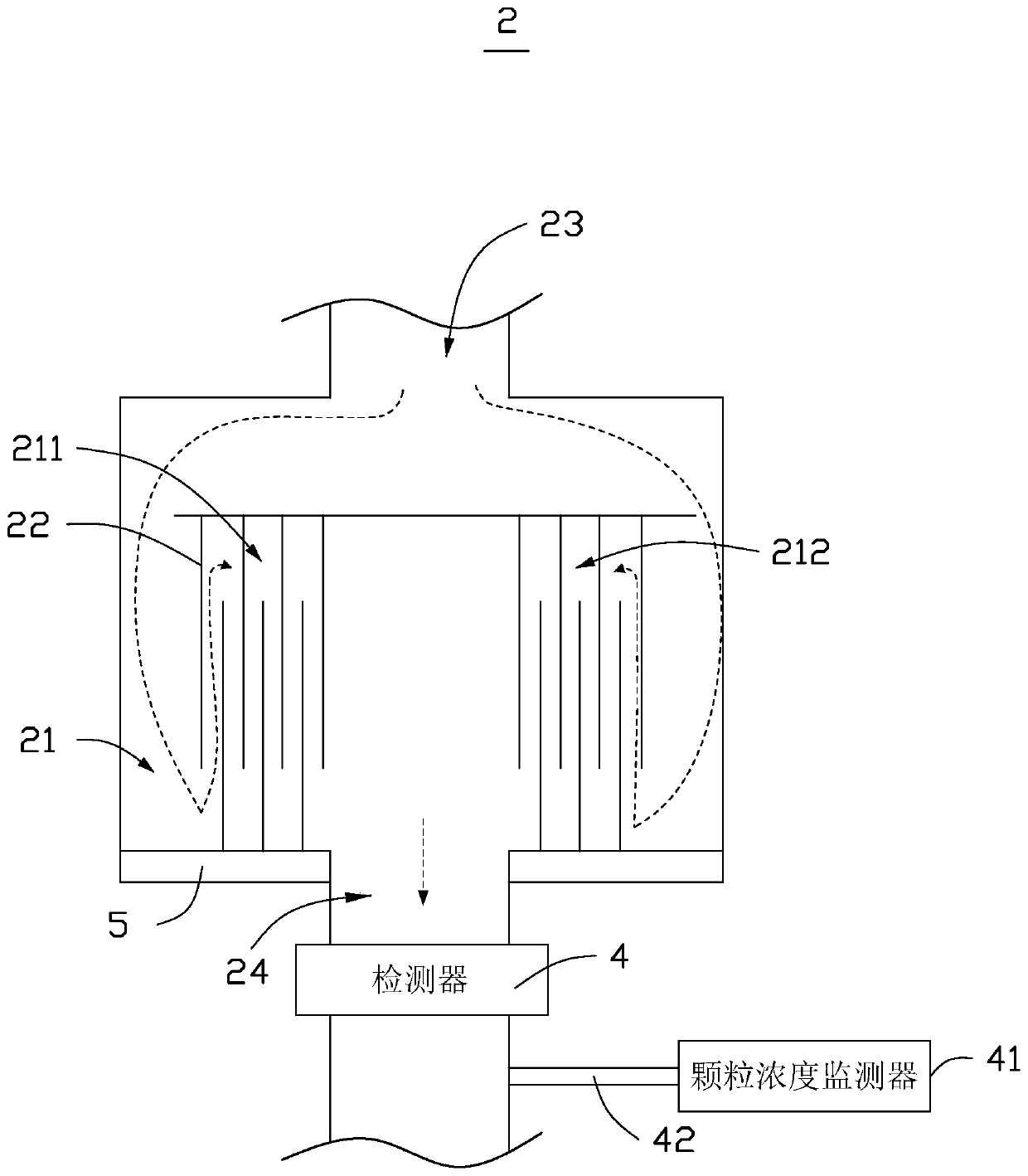

[0030] The first powder collecting device 2 includes an inner chamber 21 and a plurality of partitions 22, and the plurality of partitions 22 are arranged vertically and staggered in the inner chamber 21 for dividing the inner chamber into a plurality of mutually The communicating area forms a channel communicating with the air inlet end 23 and the air outlet end 24 of the inner chamber 21 . The channels include a first air flow channel 211 and a second air flow channel 212 arranged in parallel. The inlet port 23 of the inner cavity 21 communicates with the processing chamber 1 , and the gas outlet port 24 of the...

no. 2 example

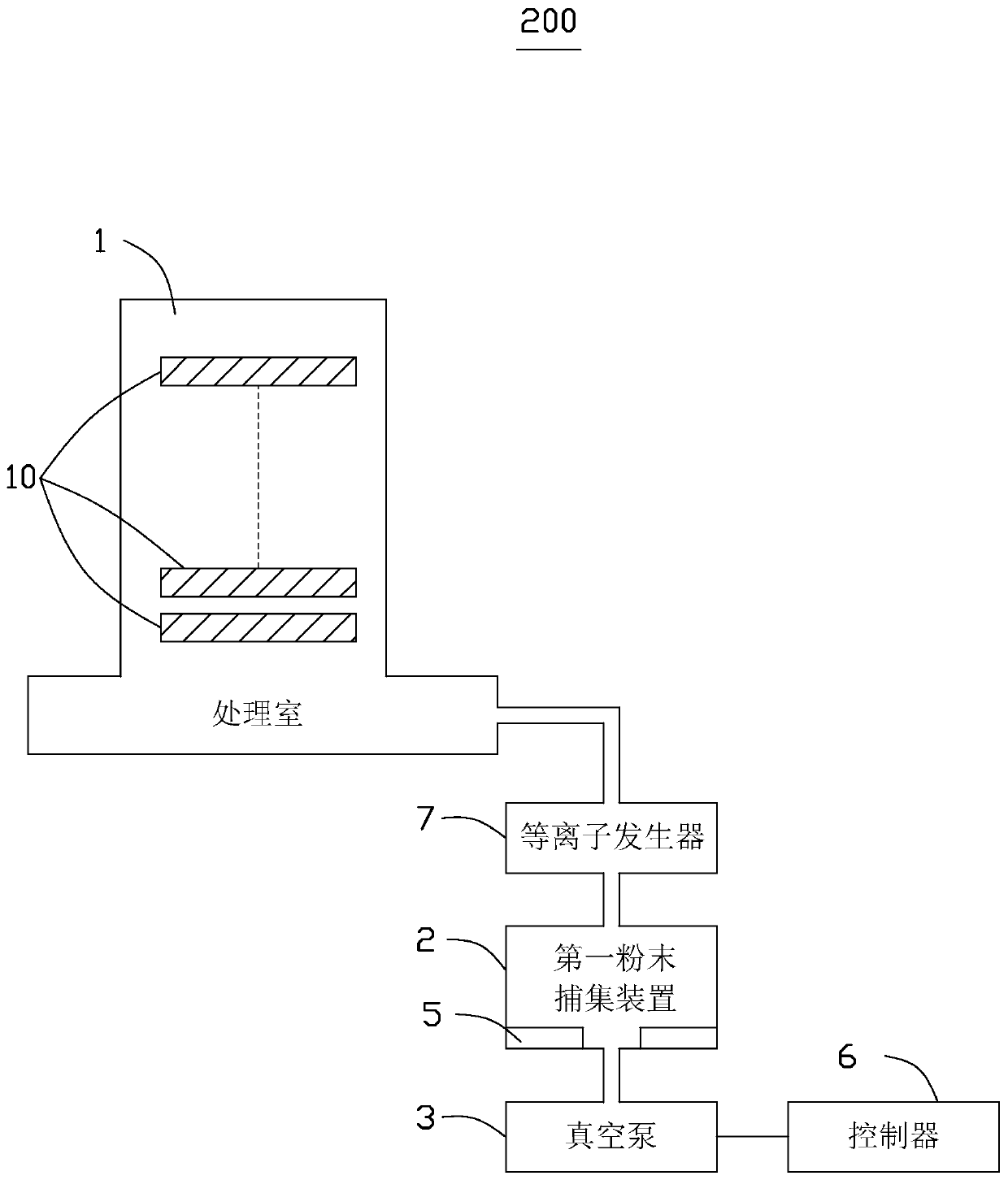

[0037] see image 3 , In the second embodiment, the powder collection system 200 includes a processing chamber 1 , a first powder collection device 2 and a vacuum pump 3 . At least one semiconductor wafer 10 is placed in the processing chamber 1 , and the first powder collection device 2 is connected between the processing chamber 1 and the vacuum pump 3 . The first powder collecting device 2 includes an inner chamber 21 and a plurality of partitions 22, and the plurality of partitions 22 are arranged vertically and staggered in the inner chamber 21 for dividing the inner chamber into a plurality of mutually The communicating area forms a channel communicating with the air inlet end 23 and the air outlet end 24 of the inner chamber 21 . The channels include a first air flow channel 211 and a second air flow channel 212 arranged in parallel. The inlet port 23 of the inner cavity 21 communicates with the processing chamber 1 , and the gas outlet port 24 of the inner cavity com...

no. 3 example

[0041] see Figure 5 , In the third embodiment, the powder collection system 300 includes a processing chamber 1 , a first powder collection device 2 and a vacuum pump 3 . At least one semiconductor wafer 10 is placed in the processing chamber 1 , and the first powder collection device 2 is connected between the processing chamber 1 and the vacuum pump 3 . The first powder collecting device 2 includes an inner chamber 21 and a plurality of partitions 22, and the plurality of partitions 22 are arranged vertically and staggered in the inner chamber 21 for dividing the inner chamber into a plurality of mutually The communicating area forms a channel communicating with the air inlet end 23 and the air outlet end 24 of the inner chamber 21 . The channels include a first air flow channel 211 and a second air flow channel 212 arranged in parallel. The inlet port 23 of the inner cavity 21 communicates with the processing chamber 1 , and the gas outlet port 24 of the inner cavity com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com