A Synchronous Flotation Method for Oxidation-Sulfide Mixed Zinc Ore

A zinc ore, lead-zinc ore technology, applied in flotation, solid separation and other directions, can solve the problems of low flotation recovery rate, long flotation process flow, complicated operation, etc., achieve short flotation process, and is conducive to recycling , easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

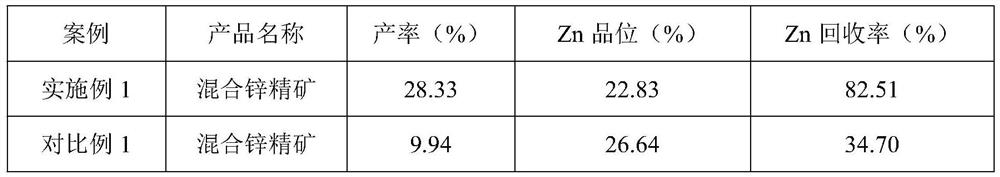

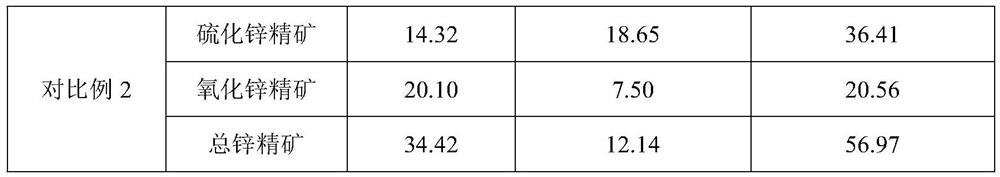

[0021] This example takes an oxidation-sulfurization mixed zinc ore in Yunnan as the object, and the ore sample contains Zn 7.35%, CaO 13.01%, SiO 2 49.97%, the oxidation rate of zinc is 70.52%, of which the distribution rate of smithsonite is 52.85%, the distribution rate of zinc silicate is 14.27%, and the other zinc oxides are mainly zinc iron spinel.

[0022] Grind the raw ore until -0.074mm accounts for more than 85%, first add 2kg / t sodium carbonate to adjust the slurry for 5 minutes, control the pH of the slurry to about 11.0, add 100g / t aluminum sulfate and 500g / t lead nitrate to activate, then add 1000g / t tCombination of inhibitors (600g / t water glass, 200g / t sodium hexametaphosphate and 200g / t dextrin) and 1000g / t fatty acid collector, stirring slurry for 10min, synchronous flotation for 7min to obtain oxide-zinc sulfide Mixed concentrates. The test results are shown in Table 1.

Embodiment 2

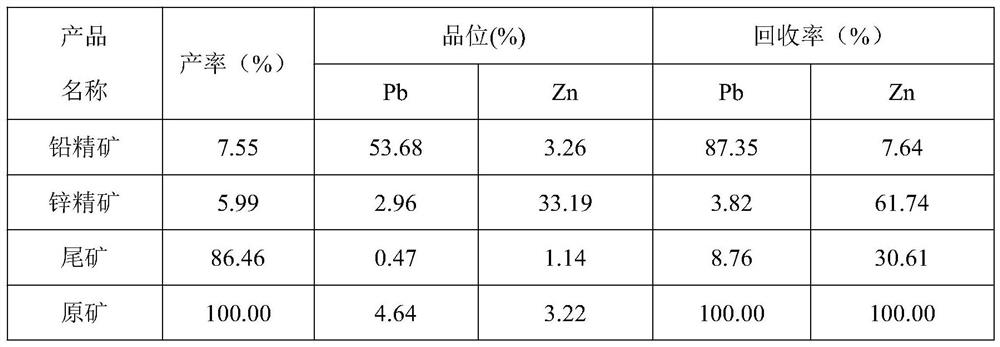

[0033] In this example, an oxidation-sulfide mixed lead-zinc ore is used as the object, and the ore sample contains 4.64% of Pb, 3.22% of Zn, 19.67% of CaO, and 19.67% of SiO 2 47.57%, TFe 2.53%, MgO 8.56%, among which the oxidation rate of lead is about 50%, and the oxidation rate of zinc is about 70%.

[0034] Grind the raw ore to -0.074mm, accounting for 85%, first add 10kg / t sodium sulfide to vulcanize, then add 200g / t pentaxanthate to flotation synchronously to produce oxidation-lead sulfide concentrate, then add 5kg / t sodium carbonate to adjust the slurry for 5min , then add 500g / t lead nitrate to activate, then add 2000g / t combined inhibitor (500g / t water glass, 300g / t sodium citrate and 1200g / t lignosulfonate) and 500g / t fatty acid collector , stirring and slurrying for 5 minutes, and synchronous flotation for 10 minutes to obtain oxide-zinc sulfide concentrate. The test results are shown in Table 2.

[0035] Table 2 Oxidation-sulfurization mixed lead-zinc ore flotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com