Underground automatic steady-flow type cyclone separator

A cyclone separator, a technology of stabilizing flow, which is applied to cyclone devices, devices whose axial direction of cyclone can be reversed, etc. Flow splitting rate and other issues to achieve the effect of ensuring the maximum efficiency separation ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

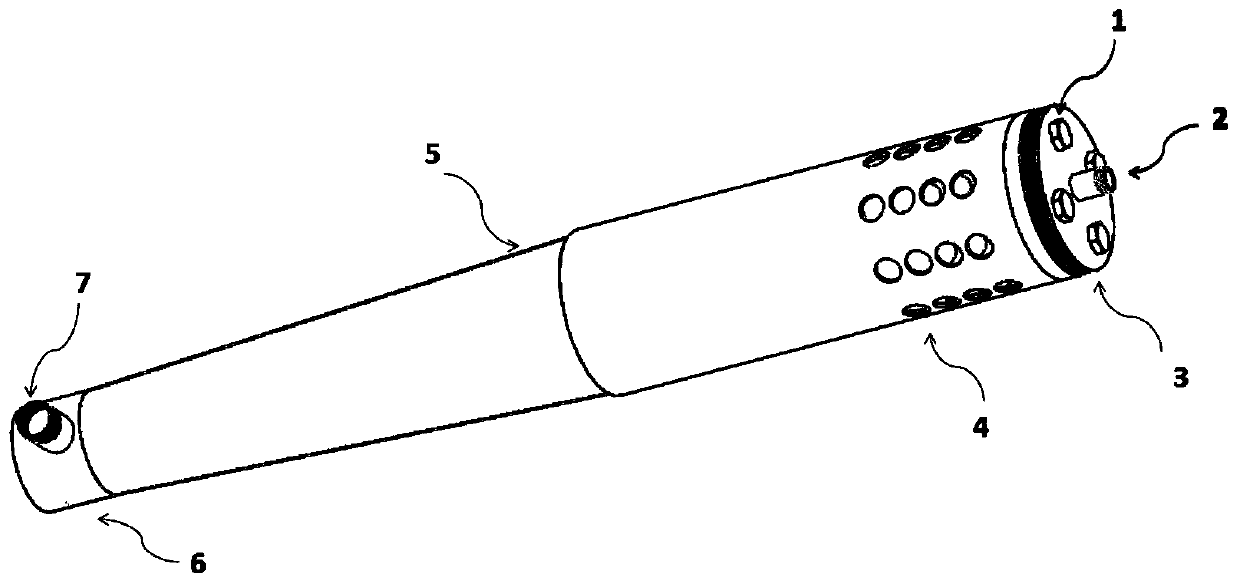

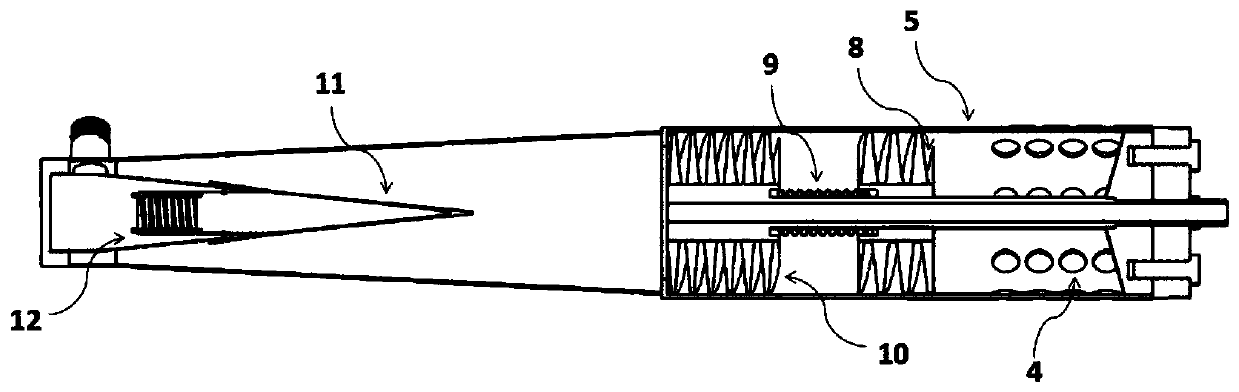

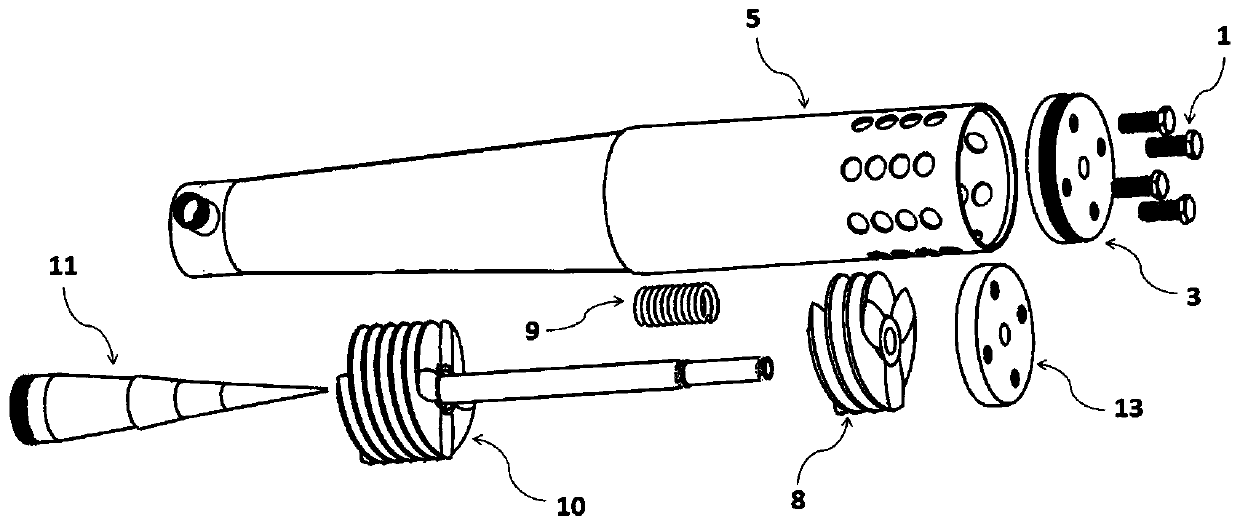

[0043] The downhole automatic steady-flow cyclone separator has a variable-diameter separation pipe 5 , a liquid inlet processing module inside the variable-diameter separation pipe, and an inverted cone structure 11 . Its unique features are:

[0044] A transparent round hole is opened at the liquid inlet of the variable-diameter separation pipe 5, and 8 rows are distributed along the circumference of the variable-diameter separation pipe at 360°, with 4 liquid inlet holes in each row; a liquid inlet processing module is installed in the variable-diameter separation pipe 5, And the inverted cone structure 11.

[0045]The liquid inlet processing module includes a large control spring 9, a static connecting rod spiral flow channel 10, a dynamic spiral flow channel 8, a stepped cone plate 13, a blocking pressure plate 3, and a locking bolt 1; the large control spring 9 and the static connecting rod spiral The flow channel 10 and the dynamic spiral flow channel 8 are assembled t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com