Grinding machine for mechanical and electrical equipment parts

A technology for electromechanical equipment and spare parts, which is applied in the field of electromechanical equipment spare parts grinding machines, can solve the problems of troublesome replacement of grinding pieces, waste of time, and increase of manual labor, so as to avoid insufficient grinding, save replacement time, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

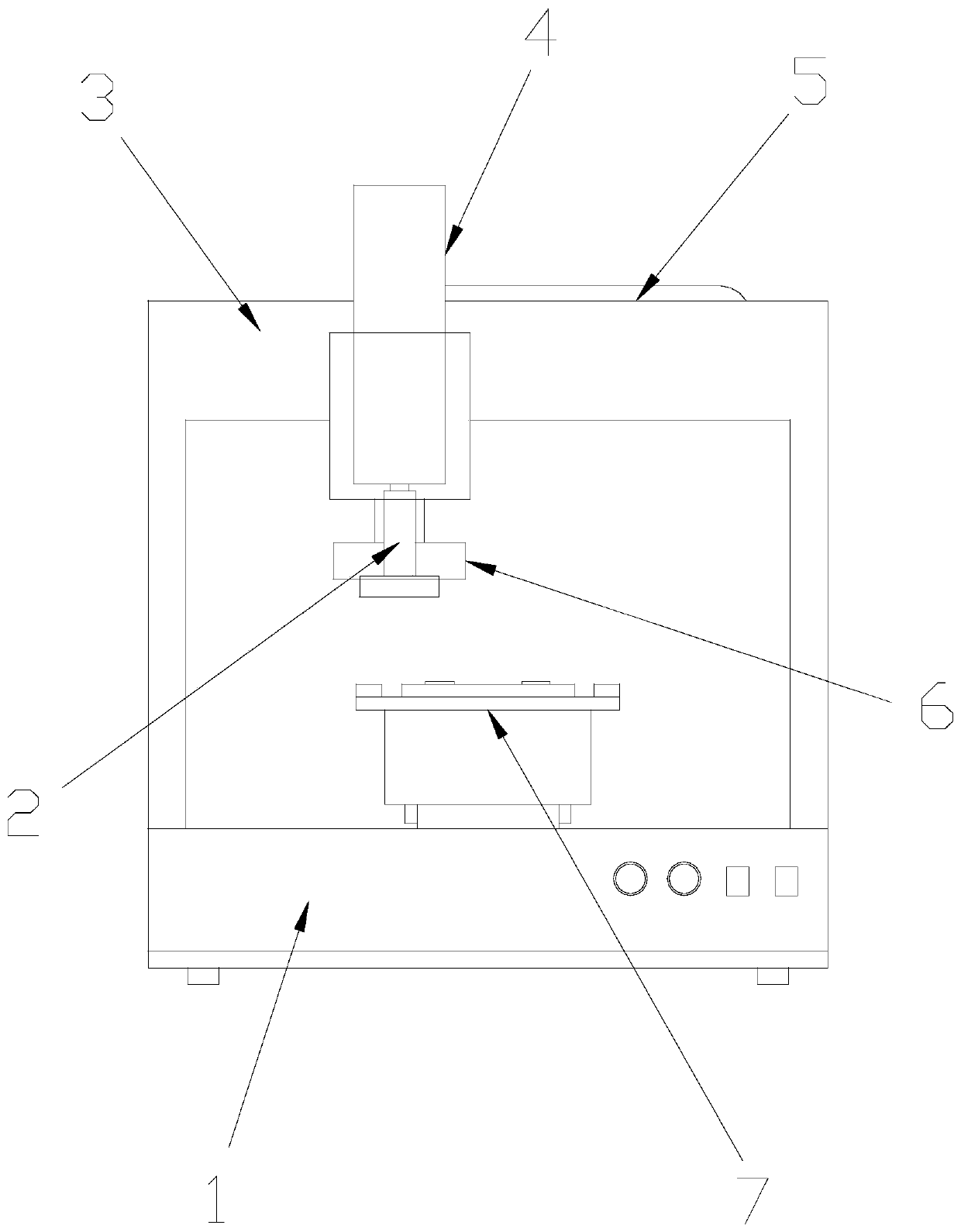

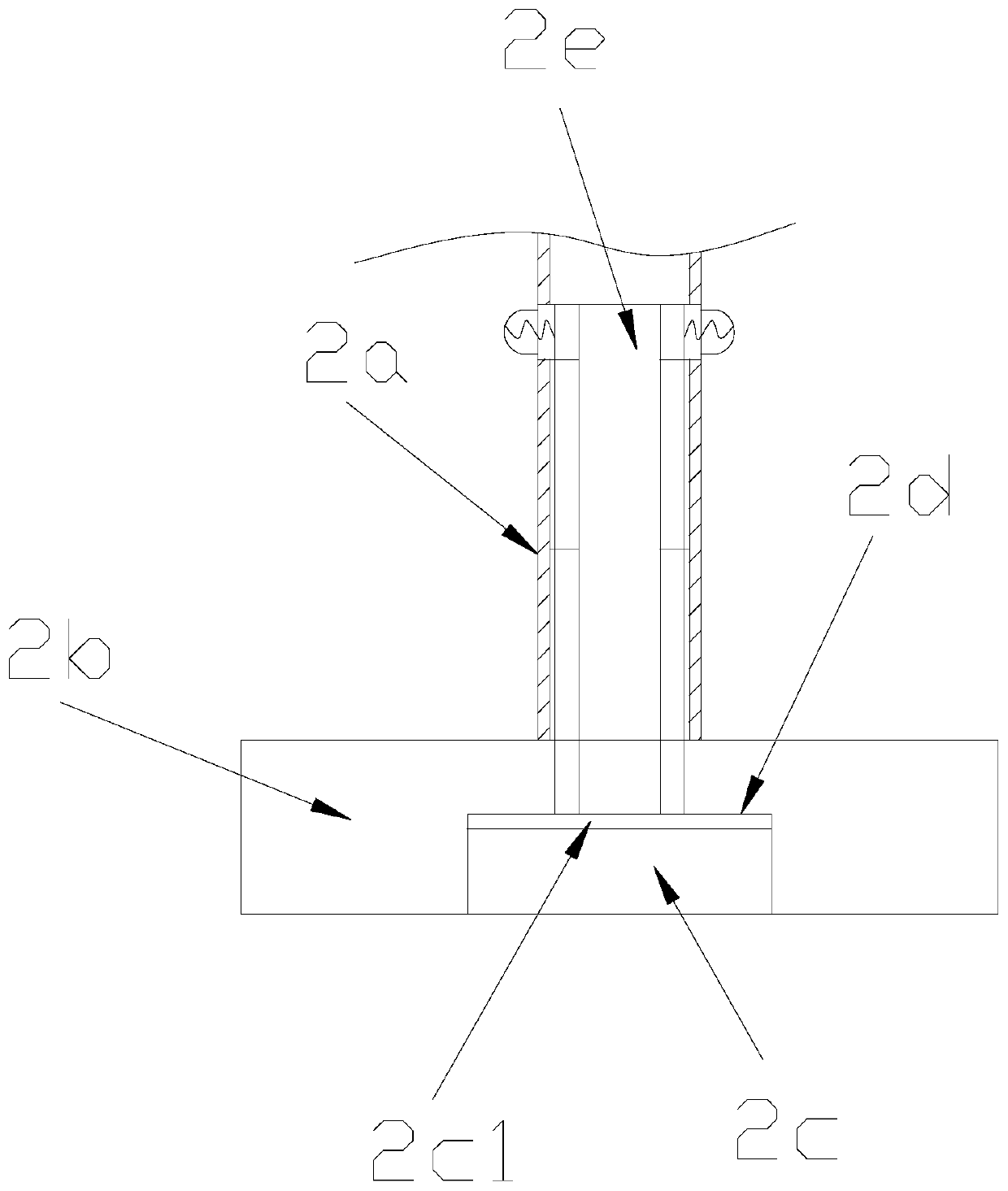

[0028] see Figure 1-Figure 4 , the present invention provides a grinding machine for spare parts of electromechanical equipment, the structure of which includes a base 1, a biaxial grinding mechanism 2, a rail frame 3, a driving device 4, a drag chain 5, a dust suppression mechanism 6, and a workbench 7. The top of the base 1 is provided with a guide rail frame 3, the base 1 and the guide rail frame 3 are mechanically connected, the middle position of the top of the base 1 is provided with a workbench 7, and the base 1 and the workbench 7 connected, the front end of the guide rail frame 3 is provided with a drive device 4, the guide rail frame 3 and the drive device 4 are connected by a drag chain 5, and the bottom end of the drive device 4 is provided with a dust suppression mechanism 6, The driving device 4 is movably connected with the dust suppression mechanism 6 , and the inner side of the dust suppression mechanism 6 is provided with a biaxial grinding mechanism 2 , and...

Embodiment 2

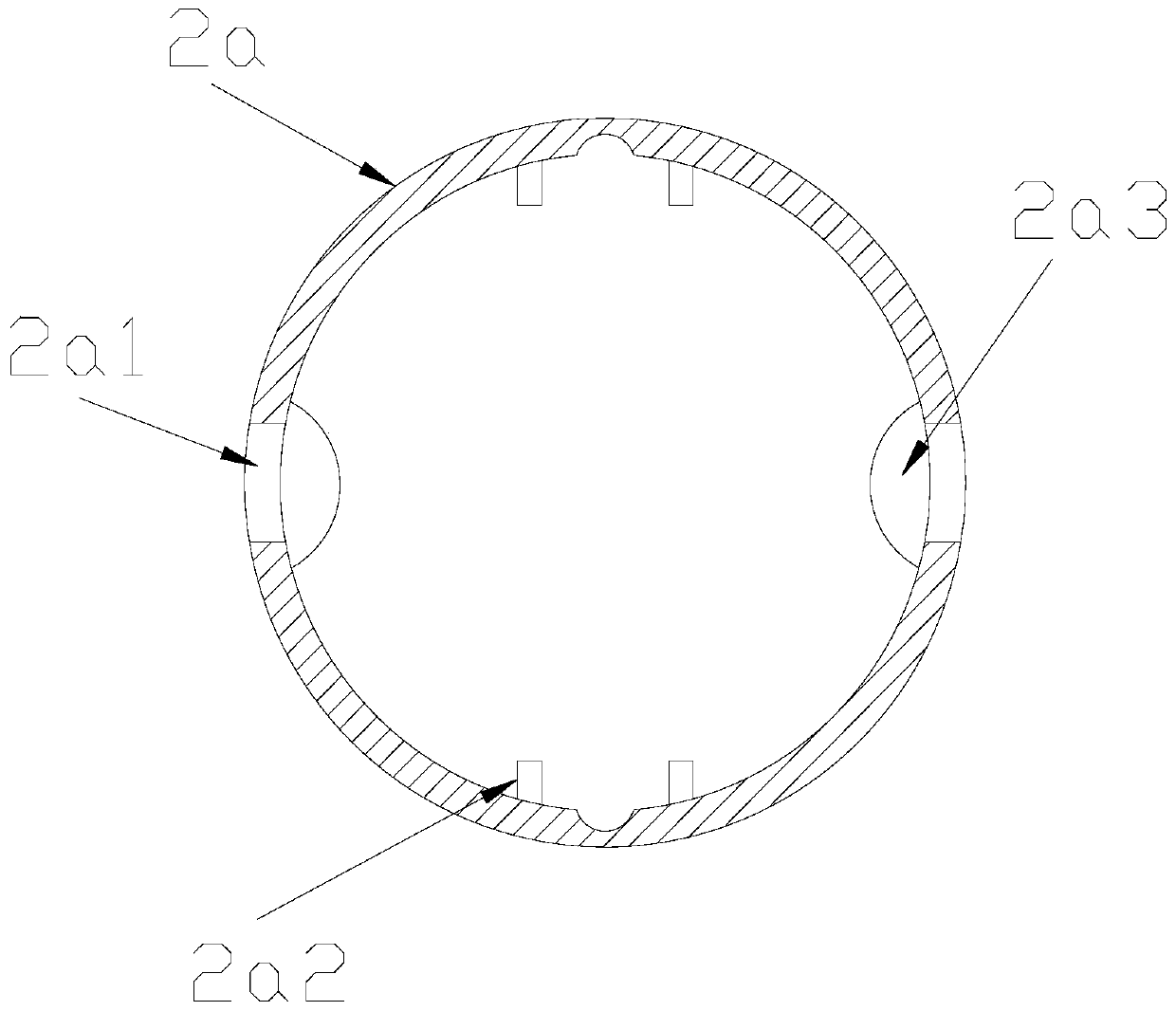

[0036] see Figure 1-Figure 6 , the present invention provides a grinding machine for spare parts of electromechanical equipment. The dust suppression mechanism 6 is composed of a fixed cylinder 6a, a negative pressure worm wheel 6b, a linkage ring 6c, a second sliding ball 6d, and a dust collection box 6e. The fixed A negative pressure worm gear 6b is provided on the inner side of the cylinder 6a. The fixed cylinder 6a and the negative pressure worm gear 6b are slidably matched through the second sliding ball 6d. A linkage ring 6c is provided in the middle of the negative pressure worm gear 6b. The negative pressure worm gear 6b is fixedly connected with the linkage ring 6c, and three dust collecting boxes 6e are equidistantly arranged on the surface of the fixed cylinder 6a.

[0037] The inner side of the fixed cylinder 6a is provided with dust-shielding blades 6a1, and the fixed cylinder 6a is fixedly connected with the dust-shielding blades 6a1.

[0038] The dust co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com