Cotton fibre opening process for manufacturing non-woven cloth

A technology of non-woven fabrics and cotton wool, which is applied in the field of non-woven fabric processing and forming equipment, can solve the problems of cotton block accumulation, etc., and achieve the effects of simple structure, increased cotton feeding efficiency, and increased work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

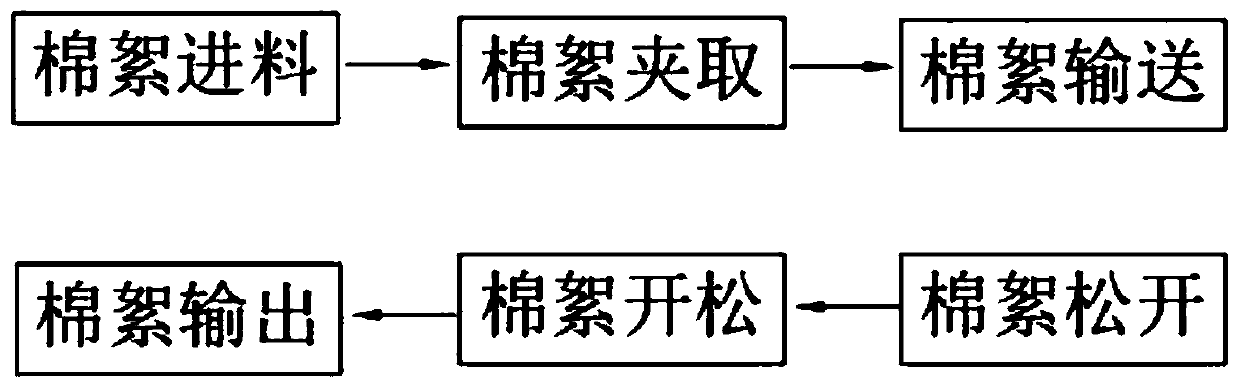

[0071] Such as figure 1 Shown, a kind of cotton wool opening process for making non-woven fabrics, it comprises:

[0072] Step 1, cotton wool feeding work, the first conveying mechanism transports the compressed cotton wool, and the feeding mechanism grabs a certain amount of cotton wool from the compressed cotton wool and transfers it to the second conveying mechanism, and the second conveying mechanism conveys the cotton wool to the first conveying mechanism. 2. The output end of the conveying mechanism;

[0073] Step 2, the cotton wool is clamped, and the clamping component clamps the cotton wool when it moves to the output end of the second conveying mechanism;

[0074] Step 3: Cotton conveying work. After the gripping component grips the cotton, it is driven by the conveyor belt to move to the top of the needling roller;

[0075] Step 4, the batting is loosened, and the clamping assembly loosens the batting when it moves to the top of the needling roller, so that the ba...

Embodiment 2

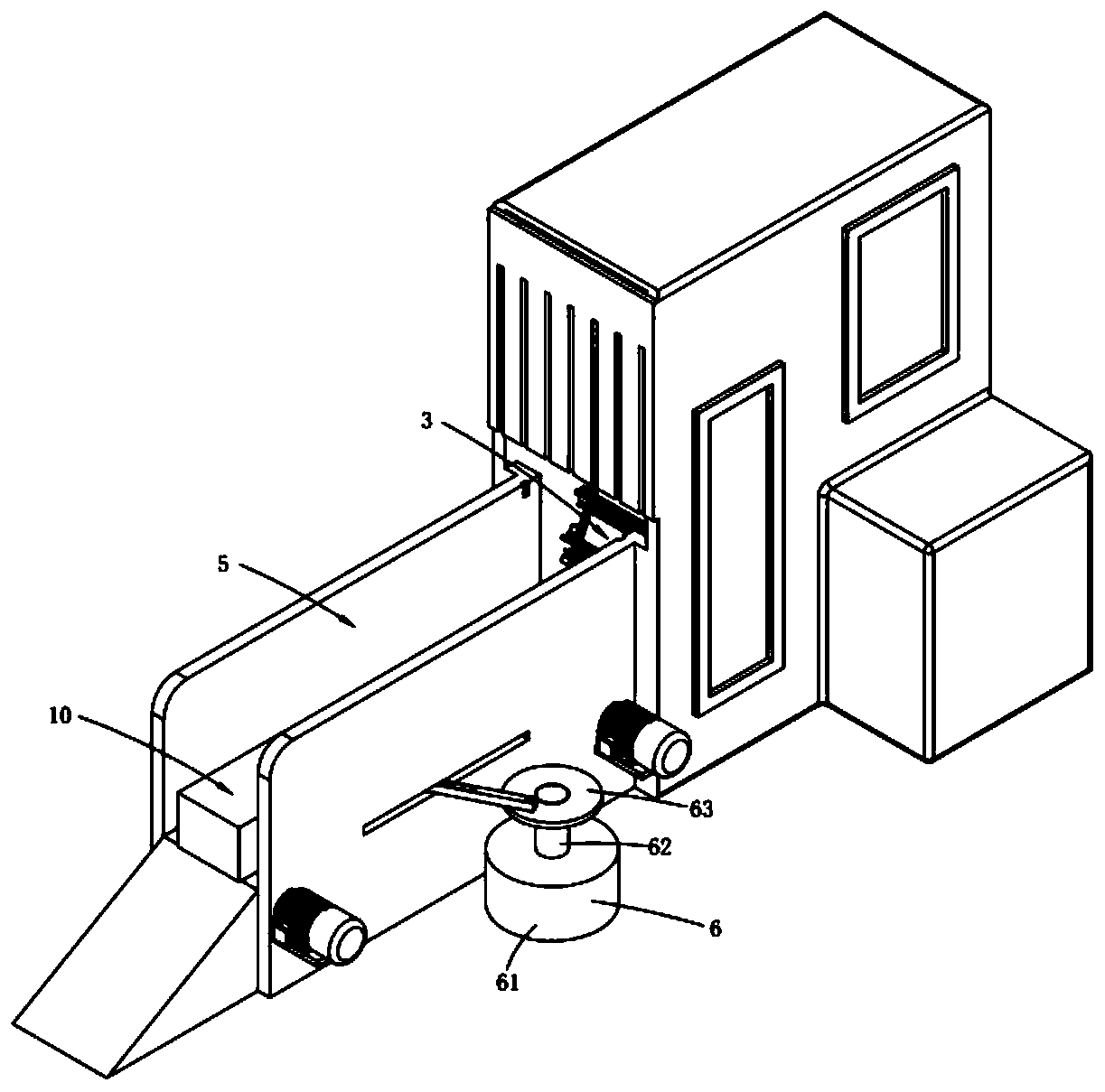

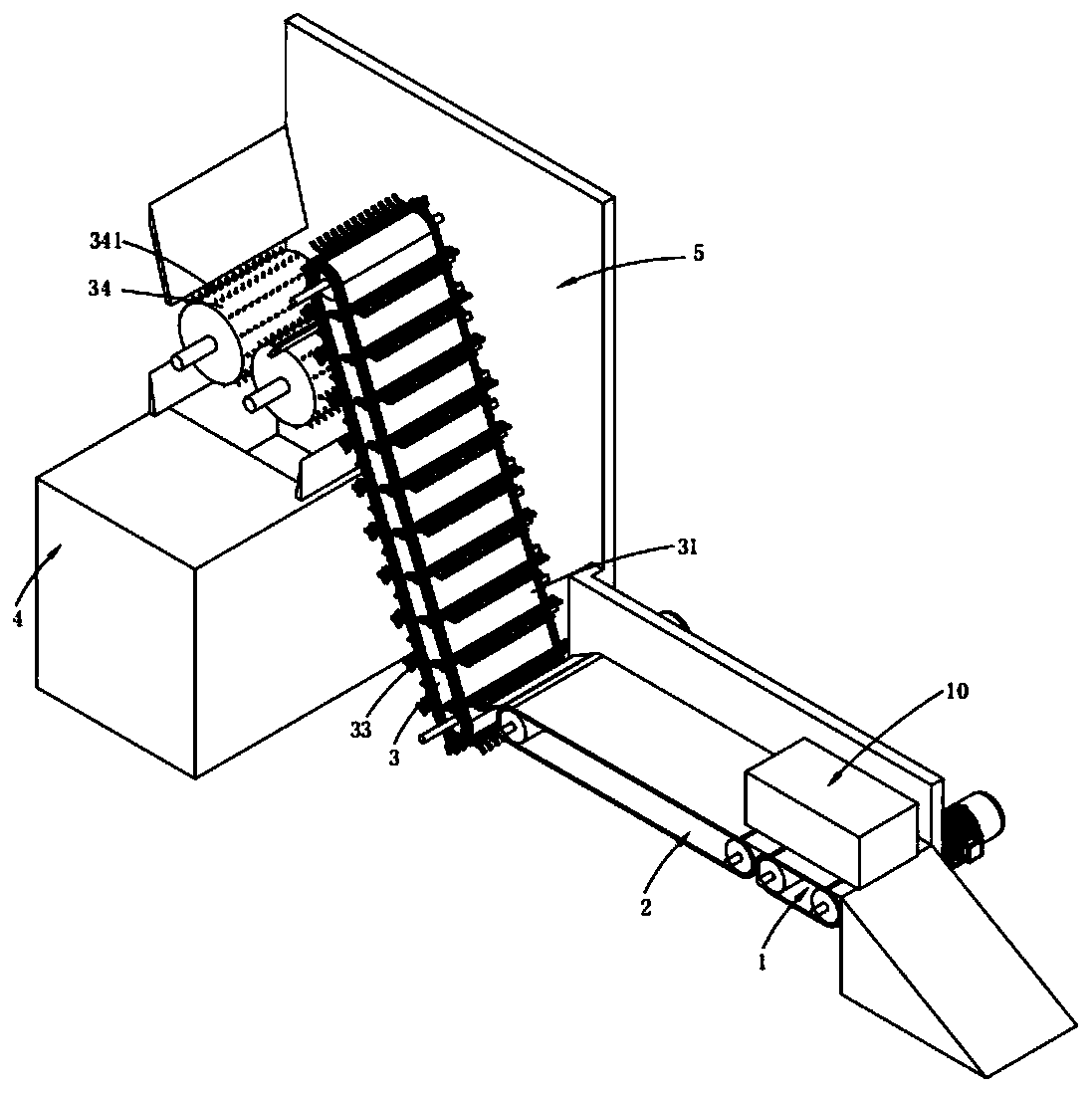

[0087] Such as figure 2 , 3 Shown in and 4, a kind of batting opening process that is used to manufacture non-woven fabric, it comprises frame 5, and the first conveying mechanism 1 that is arranged on described frame 5 successively along the length direction of described frame 5 , a second conveying mechanism 2, an opening mechanism 3 and a receiving mechanism 4, the second conveying mechanism 2 is arranged on the output end of the first conveying mechanism 1, and the opening mechanism 3 is arranged on the second conveying mechanism The output end of the mechanism 2, the receiving mechanism 4 is arranged below the output end of the opening mechanism 3, and the opening mechanism 3 includes:

[0088] Conveyor belt 31, and described conveyer belt 31 is arranged obliquely;

[0089] track 32, the track 32 is symmetrically arranged on both sides of the conveyor belt 31;

[0090] Clamping components 33, the clamping components 33 are arranged on the surface of the conveyor belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com