Air filter system having self-cleaning function

An air filter and self-cleaning technology, which is applied in the field of air filter system with self-cleaning function, can solve problems such as manual operation, and achieve the effects of protecting life, reducing quantity, and ensuring human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

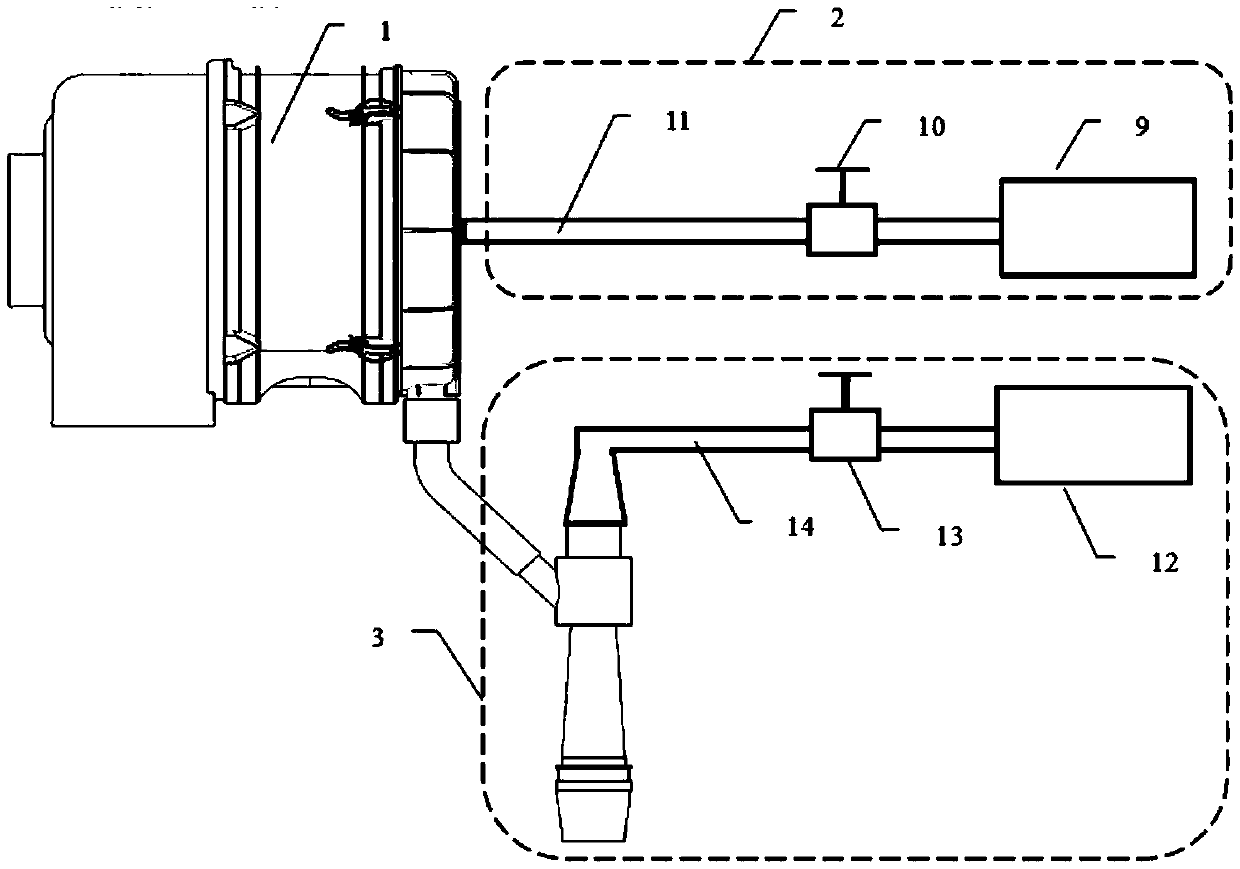

[0027] Such as figure 1 As shown, an air filter system with self-cleaning function includes three parts: an air filter 1 , a self-cleaning device 2 and a self-dust exhausting device 3 .

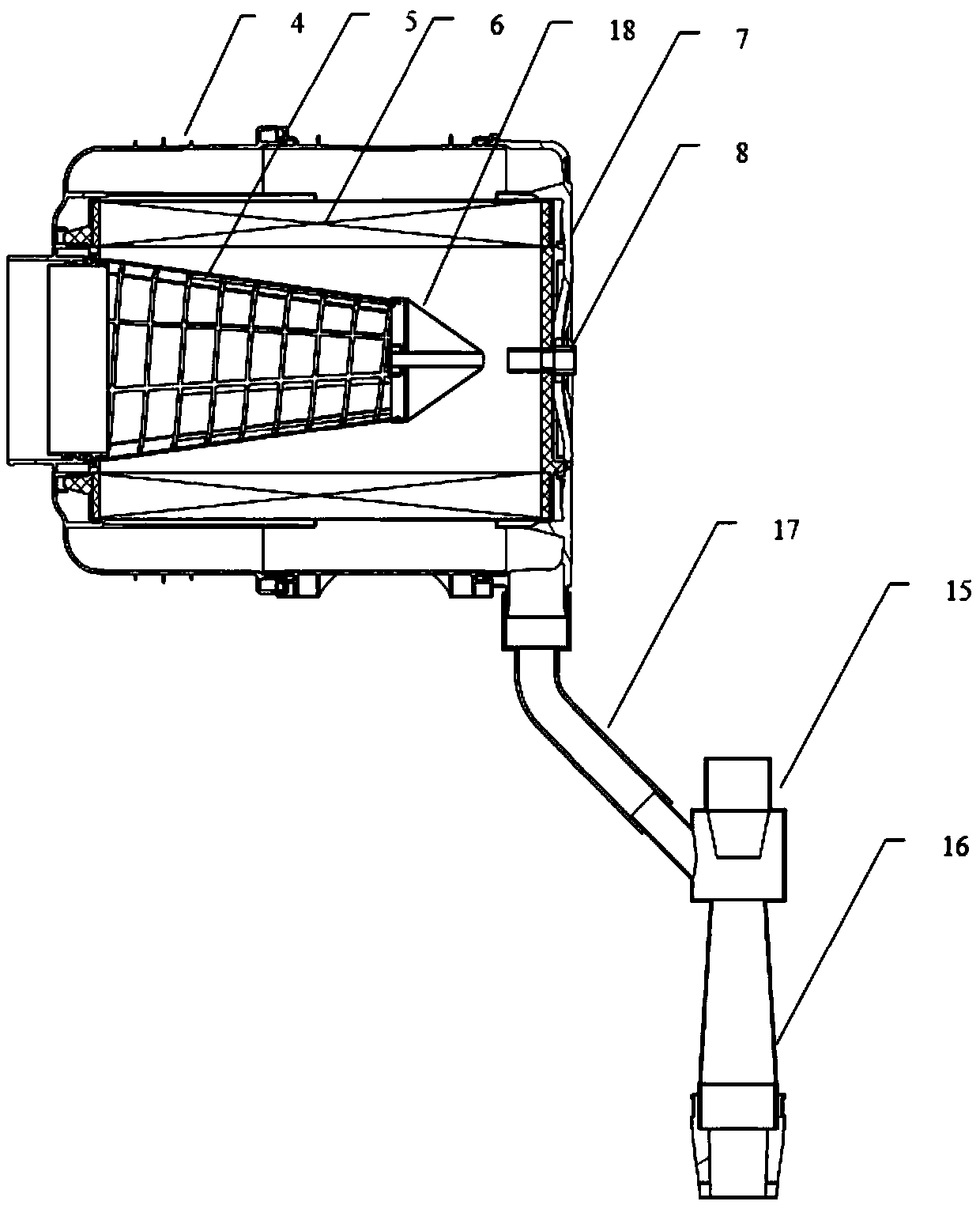

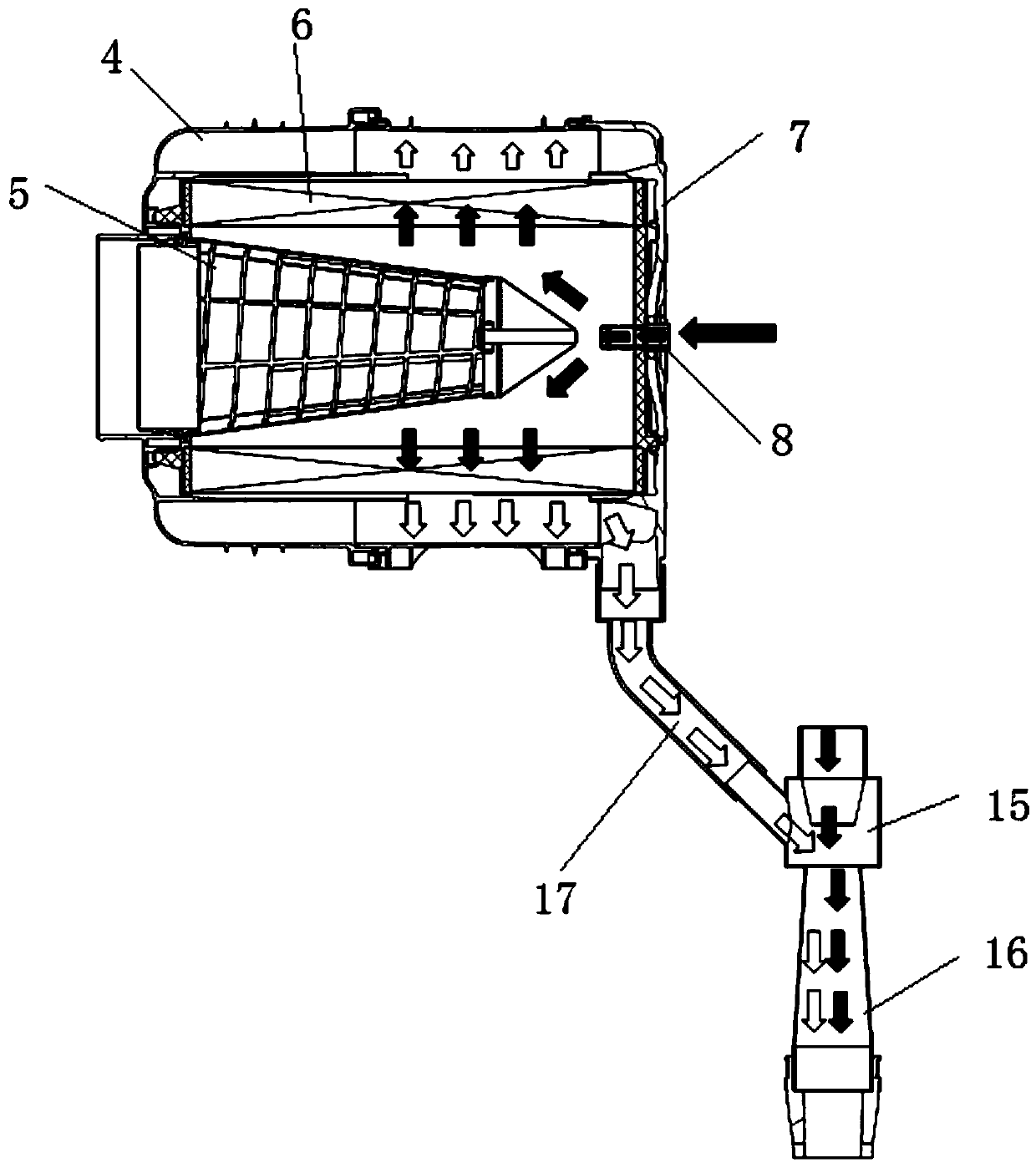

[0028] Wherein, the air filter 1, such as figure 2 As shown, it includes a casing 4, a safety filter element 5, a main filter element 6 and a cover 7. The safety filter element 5 is located at the center of the casing 4, and the main filter element 6 is located at the periphery of the safety filter element 5, through its two end covers It is assembled with the cover 7 or the shell 4, and the shell 4 and the cover 7 are fixed by buckling. The top of the safety filter element 5 is provided with a shroud 18, the shroud 18 has a bullet-shaped structure, its top is spherical, and its side is conical, so that the blowback gas introduced from the self-cleaning device 2 is evenly dispersed in all directions. , the dispersed air flow blows up the external particles of the main filter element 6 from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com