A kind of garbage harmless incineration device

An incineration device and harmless technology, applied in the direction of incinerators, combustion types, combustion methods, etc., can solve problems such as incomplete combustion of garbage, unfavorable environment, environmental pollution, etc., to improve injection capacity, improve crushing performance, and ensure The effect of crushing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

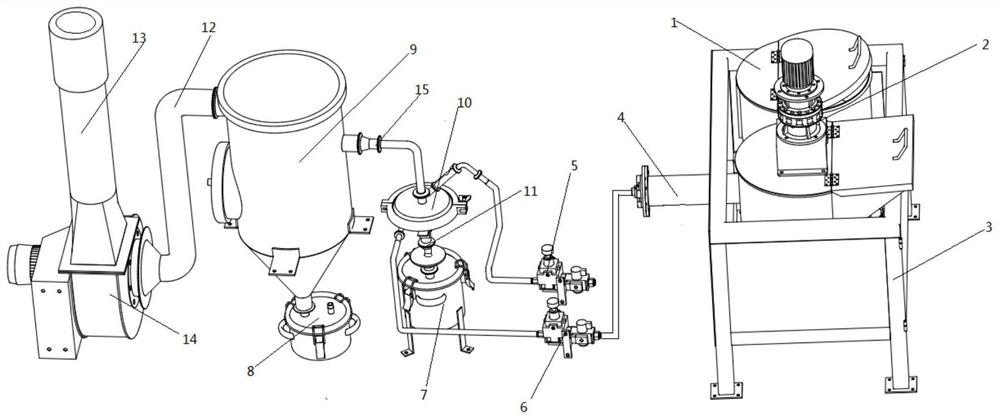

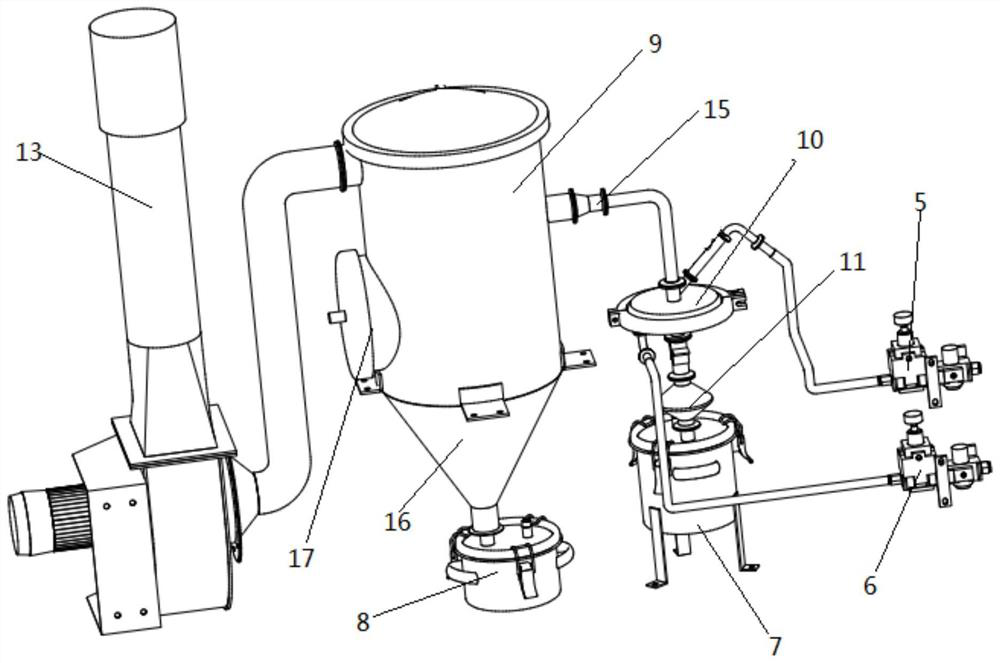

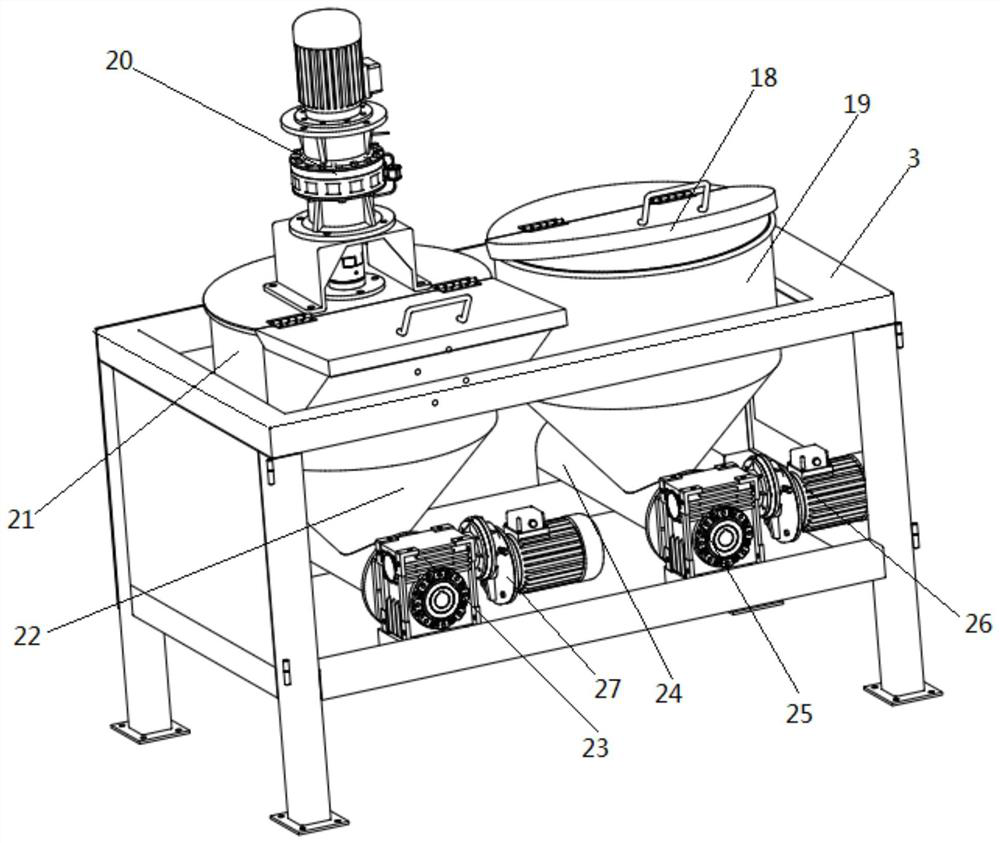

[0020] see Figure 1~3 , in an embodiment of the present invention, a garbage harmless incineration device, including a garbage pretreatment mechanism, a mixing and pressurized injection mechanism, a combustion aid adding mechanism 5, an incinerator 9 and an exhaust gas treatment mechanism, characterized in that the garbage The output end of the pretreatment mechanism is connected to the mixing and pressurizing injection mechanism, and the combustion aid adding mechanism is also connected to the mixing and pressurizing injection mechanism, and the output end of the mixing and pressurizing injection mechanism is connected to the Incinerator 9, the bottom of the incinerator 9 is connected to the oxygen supply mechanism 8, and the top of the incinerator is also connected to the tail gas treatment mechanism, wherein the garbage pretreatment mechanism is configured to be able to crush the garbage and The pulverized garbage can be mixed and delivered to the mixing and pressurized in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com