Method and device for chemical-looping incinerating garbage

A technology of incineration of garbage and chemical chain, applied in the field of garbage treatment, can solve problems such as insufficient garbage incineration process, unstable incineration process, and generation of toxic substances such as dioxin, so as to achieve stable garbage incineration process and avoid drying and thermal decomposition , the full effect of garbage incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

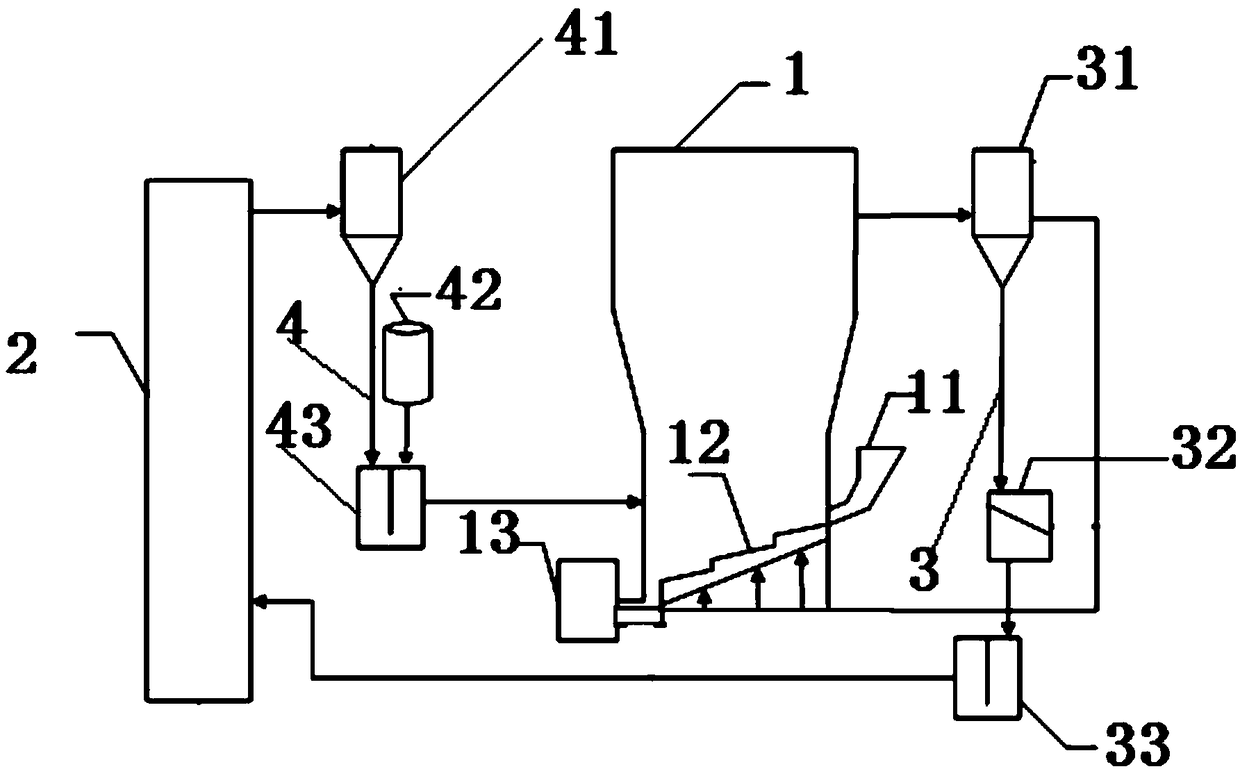

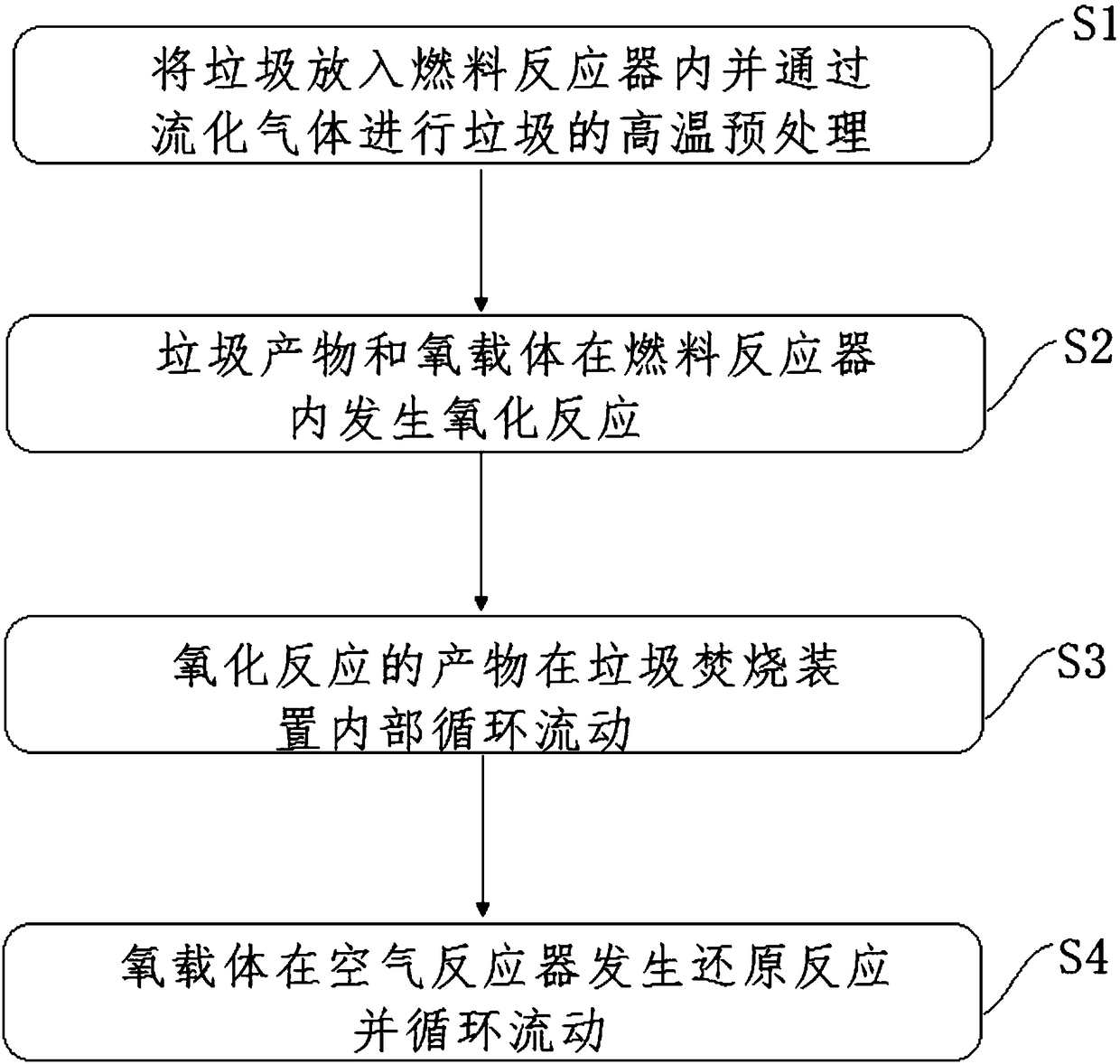

[0041] like figure 2 Shown, the present invention discloses a kind of method of chemical chain incineration rubbish, described method comprises the following steps:

[0042] S1: Pour the garbage into the fuel reactor 1, first dry the garbage through the fluidization gas, and at the same time use the fluidization gas to thermally decompose the dried garbage to obtain carbonized garbage and garbage residues, and then perform gasification reaction on the carbonized garbage; steps The fluidization gas mentioned in S1 is CO with a temperature of 800-1000°C 2 It provides the required heat for the drying, pyrolysis and gasification of the garbage and provides the gasification agent for the gasification reaction, and at the same time avoids drying and drying the garbage with the help of external heat sources during the pretreatment of the garbage. Thermal decomposition, which further reduces the cost of the waste incineration process.

[0043] S2: The oxidized oxygen carrier is intro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com