A simulation test system for the whole process of dynamic evolution of dam-break debris flow

A simulation test system and debris flow technology, applied in teaching models, soil material testing, material inspection products, etc., can solve the problems of not being able to meet the requirements of high-speed camera light sources, the difficulty of locking the baffle, and the sharp increase in weight, etc., to achieve The effect of preventing irreversible damage, simple assembly, and strong simulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

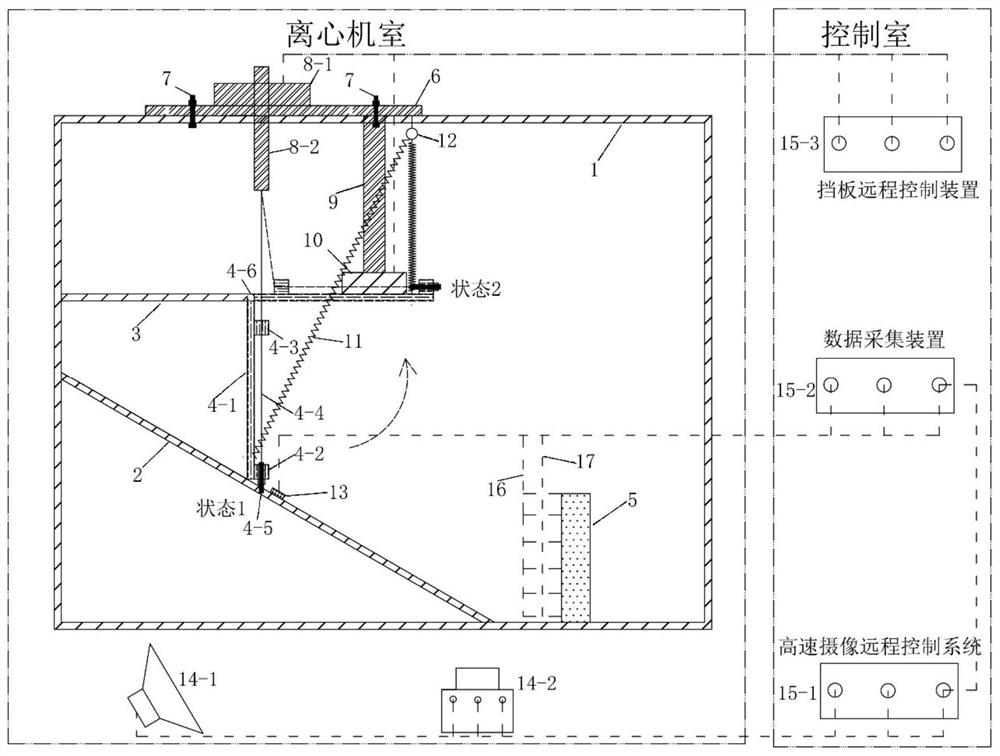

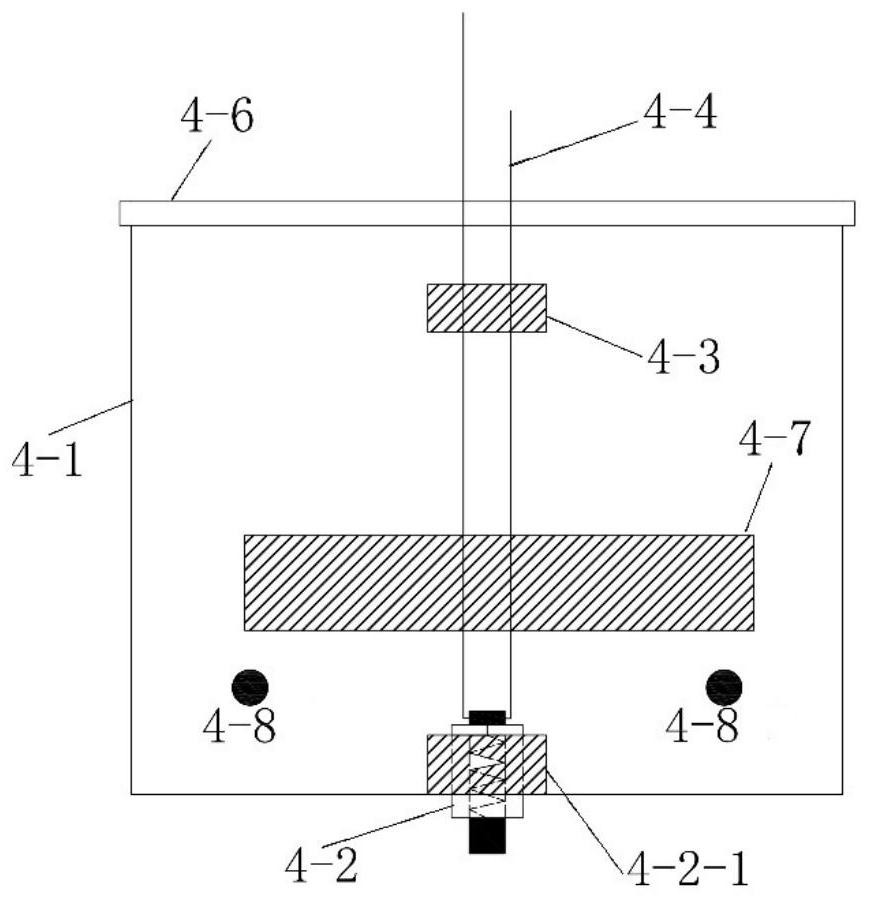

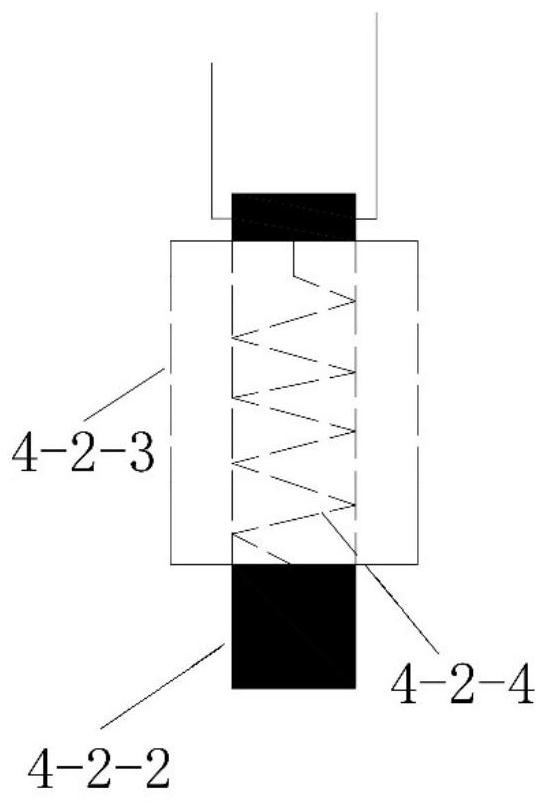

[0042] like figure 1 As shown, this application proposes a simulation test system for the whole process of dynamic evolution of dam-break debris flow, which is suitable for the high-gravity centrifugal test platform, including: a model box 1, which is located in the centrifuge room, and is used to simulate the start-up, movement, impact and impact of debris flow. The whole process of dynamic evolution of stacking includes the storage box 3, the baffle plate 4, the sliding surface 2, the blocking structure 5, and the motor 8. The plate 4 is rotatably arranged at the outlet of the material storage box 3 toward the bottom of the sliding surface 2, and the motor 8 controls the opening of the baffle plate 4; the data acquisition system includes the sensor arranged in the model box 1, and the data acquisition system connected with the sensor Device 15-2, data acquisition device 15-2 is arranged in the control room; High-speed camera system is located in the centrifuge room, includin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com