High-temperature thermal field and complex atmosphere environment static coupling device

An atmosphere environment and coupling device technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to provide multi-component oxidation and corrosive atmosphere environment, low reliability of test data, single gas composition, etc., to achieve The effect of protecting the body's health, simple and reliable structure, and strong atmosphere simulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

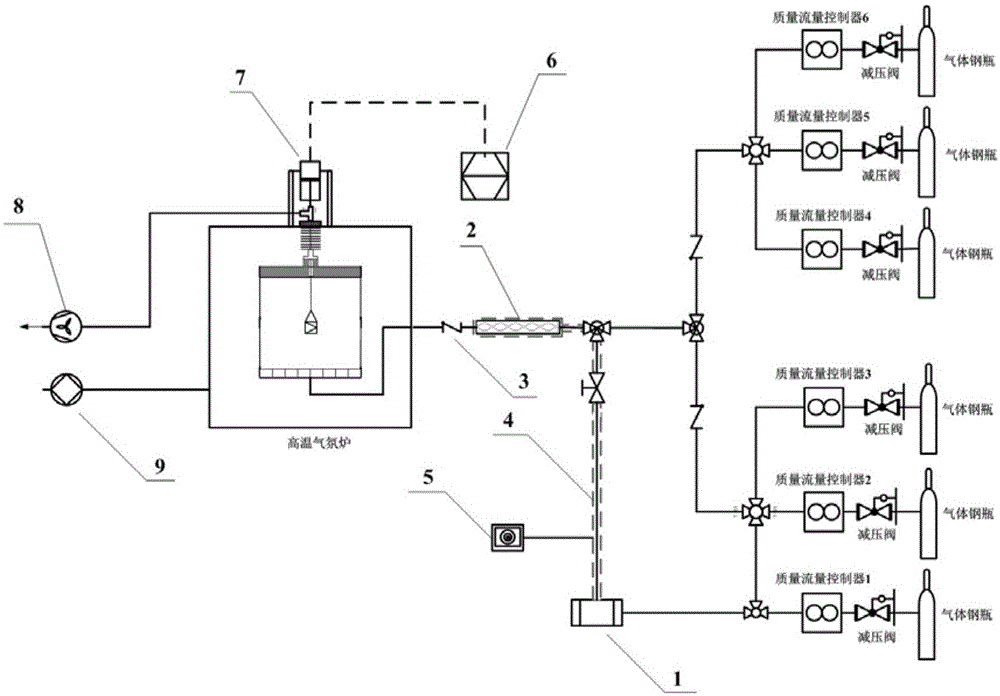

[0028] Utilizing the present invention, the simulated temperature is 1500°C, and the gas composition is N 2 70%, O 2 20%, CO1%, CO 2 8%, SO 2 0.2%, SO 3 0.8% high-temperature gas atmosphere environment: put the sample to be tested in the test dish suspended by the platinum-rhodium alloy suspension wire 18, close the high-temperature atmosphere furnace 13, set the heating program, and wait until the temperature rises to 1500°C and enters the constant temperature stage. Rotate the ferrule three-way valve and close the ferrule ball valve at the same time to switch to the gas environment gas circuit. Open the switch of various types of gas high-pressure gas cylinders 15, connect the power supply of gas mass flow controller 22, set the flow value of various types of gases according to the ratio of the gas composition: N 2 ~350mL / min, O 2 ~100mL / min, CO~5mL / min, CO 2 ~40mL / min, SO 2 ~1mL / min, SO3 ~4mL / min, turn on the duct fan 28 to exhaust the exhaust gas. Data recording an...

Embodiment 2

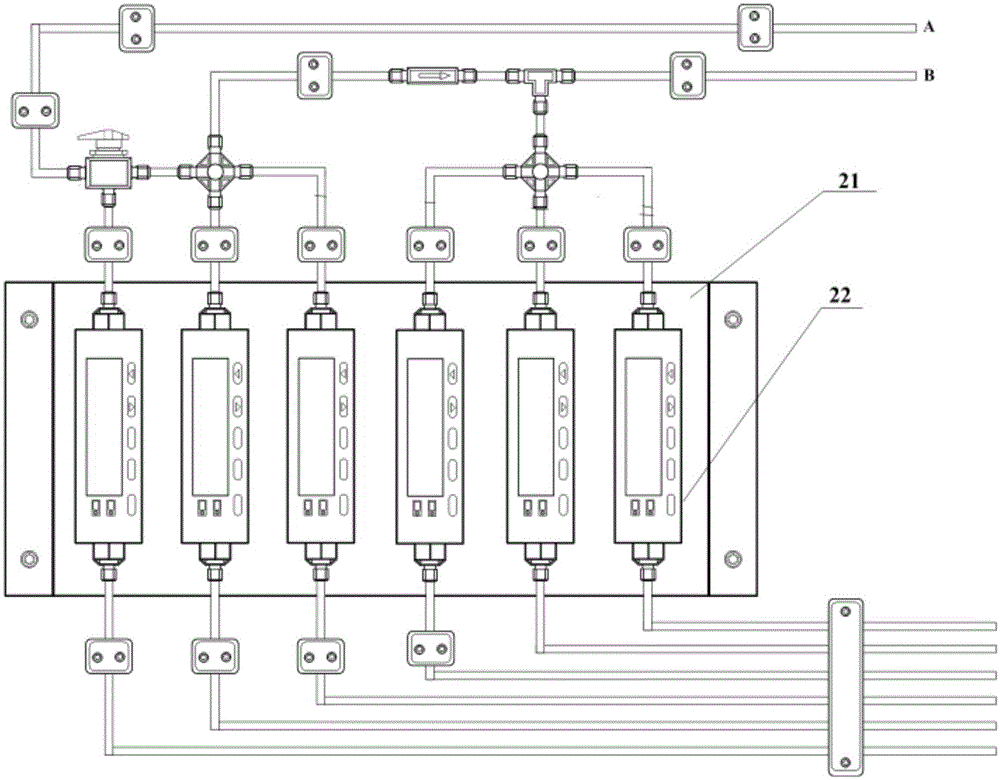

[0030] Using the present invention to simulate the temperature is 1400°C, air+10%H 2 O water and oxygen environment: put the sample to be tested into the test dish suspended by the platinum-rhodium alloy suspension wire 18, close the high-temperature atmosphere furnace 13, set the temperature rise program, and wait for the temperature to rise to 1400°C and enter the constant temperature stage, then rotate the card Set the three-way valve, and open the ferrule ball valve at the same time, switch to the water-oxygen environment gas circuit. Set the preheating temperature on the gas preheating pipeline thermostat 5 to 100°C, turn on the gas preheating pipeline 4 and preheat for 20 minutes, then turn on the steam generator 1 and set the parameters until the generated humidity is 10% h 2 O. open N 2 and O 2 The gas high-pressure gas cylinder valve is connected to the N installed on the installation base 21 2 and O 2 The power supply of the high-precision gas mass flow control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com