Junction box photovoltaic module and manufacturing method thereof

A technology of photovoltaic modules and junction boxes, applied in the direction of photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of exceeding the inner height of the container, unable to use three-part junction box circuit connection, unable to gather together, etc., to reduce work The effect of current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

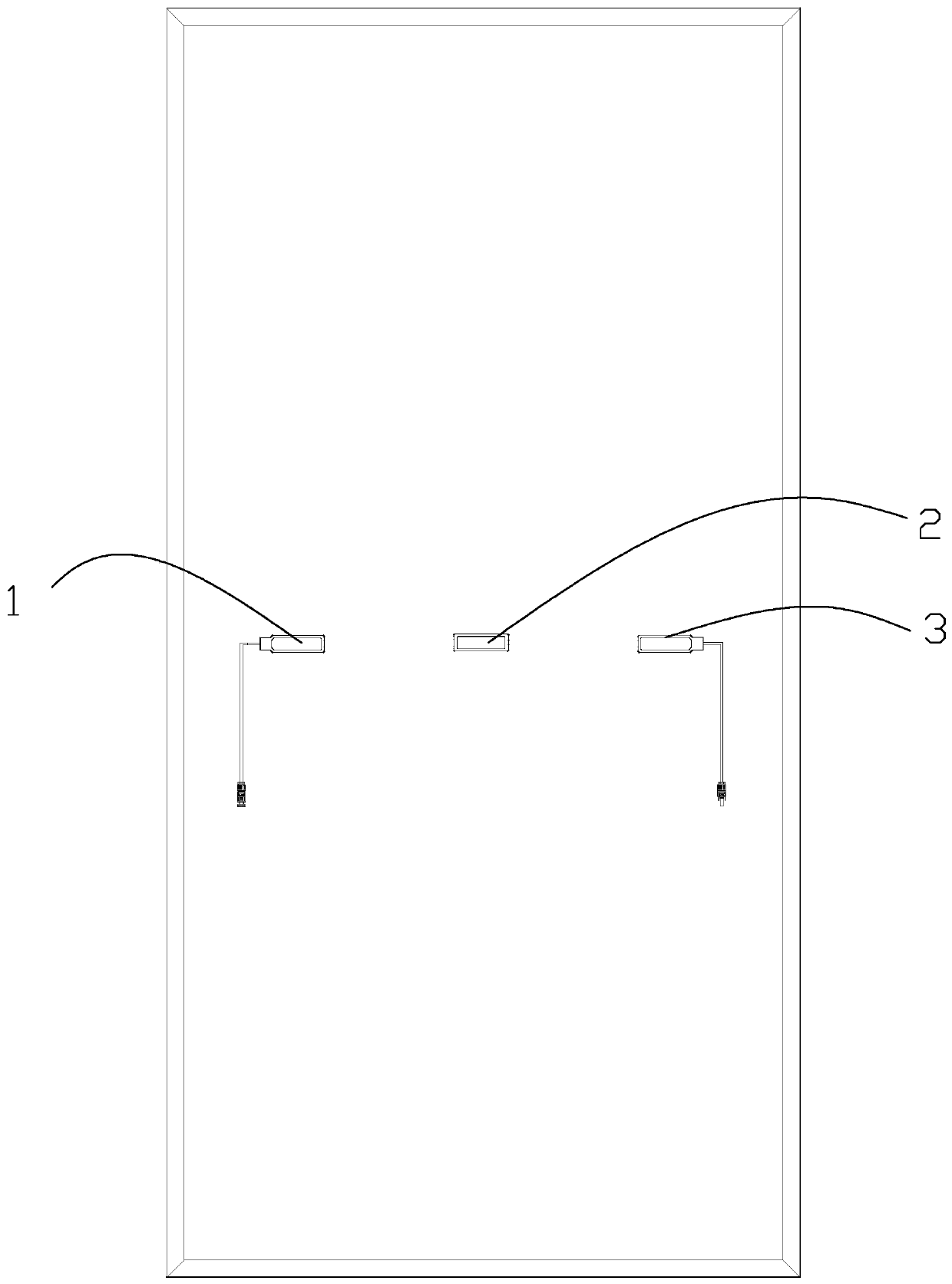

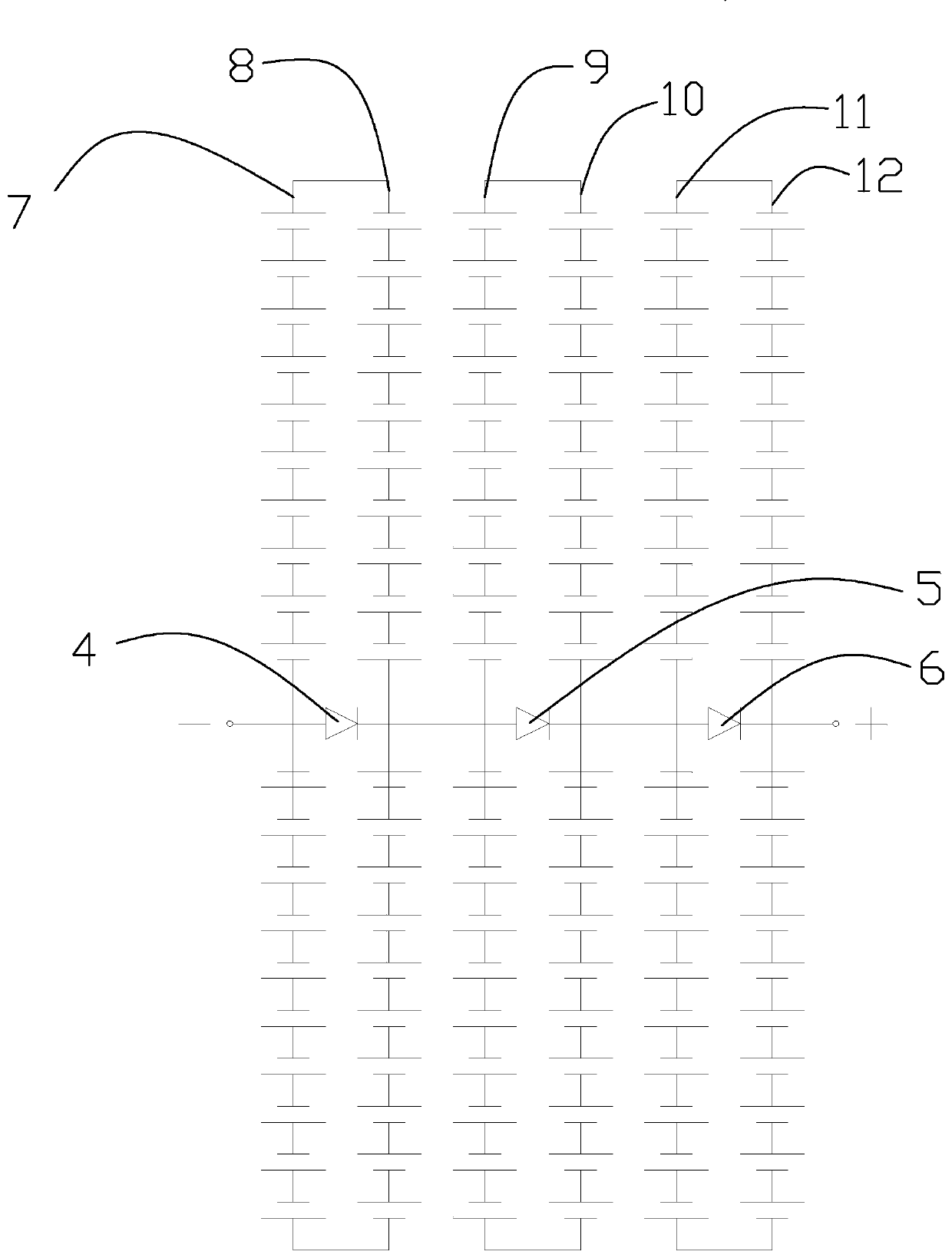

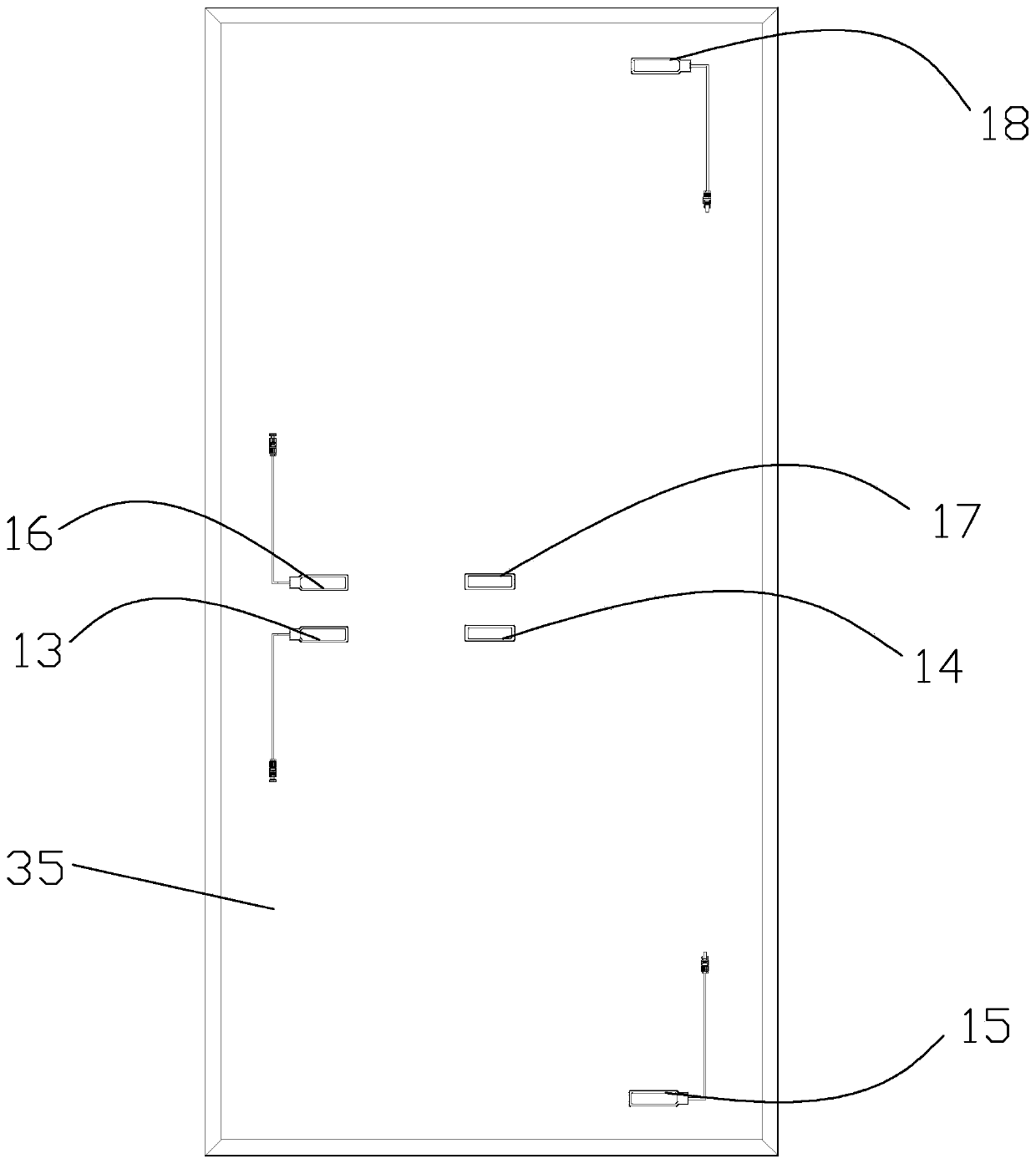

[0023] As shown in the figure, the present invention provides a junction box photovoltaic assembly, including a photovoltaic cell panel 35, five strings of cells are arranged on the photovoltaic cell panel 35, and first wirings are respectively provided on the back of the photovoltaic cell panel 35. Box 13, second junction box 14, third junction box 15, fourth junction box 16, fifth junction box 17 and sixth junction box 18, the first junction box 13 includes a negative output terminal and a first bypass Diode 20, the fourth junction box 16 includes a negative output terminal and a second bypass diode 19, the second junction box 14 includes a third bypass diode 22, and the fifth junction box 17 includes a fourth Bypass diode 21, the third junction box 15 includes a positive output terminal and a fifth bypass diode 24, the sixth junction box 18 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com