LED display module and manufacturing method thereof

A technology for display modules and manufacturing methods, which is applied in the direction of printed circuits, printed circuits, and electrical components connected to non-printed electrical components, and can solve problems such as poor heat dissipation, light decay, small lead welding force, and large device volume. Achieve the effect of improving strength, improving production efficiency, and uniform luminescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

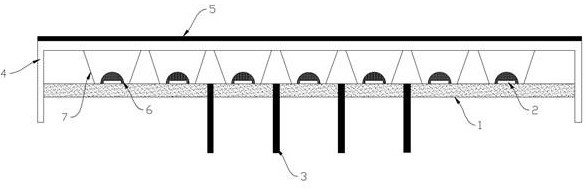

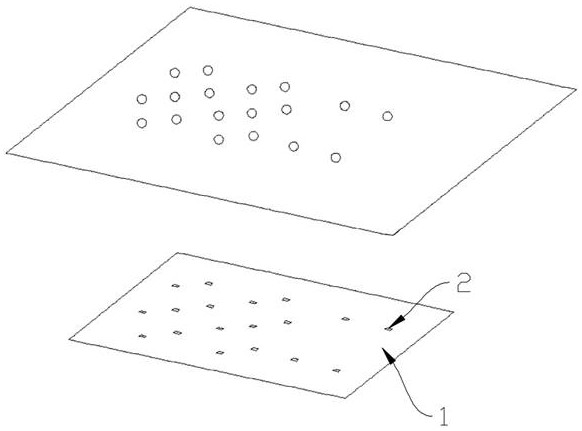

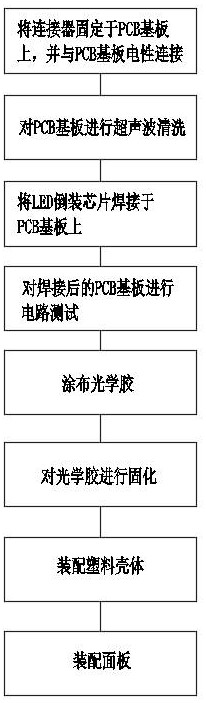

[0027] Such as figure 1 The shown LED display module includes a PCB substrate 1 and an LED flip chip 2, the bottom of the PCB substrate 1 is electrically connected to several connectors 3, and the LED flip chip 2 is mounted on the PCB substrate 1 The upper end surface of the LED flip chip 2 is electrically connected to the PCB substrate 1, a layer of plastic shell 4 is provided directly above the PCB substrate 1, and a layer of panel is provided on the upper end of the plastic shell 4. 5. The circuit pins of the LED flip chip 2 are bound to the pads of the PCB substrate 1 through soldering, and the LED flip chip 2 is packaged on the PCB substrate 1 through optical glue 6, so The optical adhesive 6 completely covers the LED flip chip 2; the optical adhesive 6 is doped with phosphor powder; the bottom surface of the plastic shell 4 is uniformly provided with s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| curing dosage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com