Machining method of multi-angle tiny square groove

A processing method and a technology of square slots, which are applied in the direction of electrical components, printed circuit manufacturing, printed circuits, etc., can solve problems affecting product quality, cannot be added to the lower hole, and move left and right, so as to improve processing quality, simplify processing, and avoid bump effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

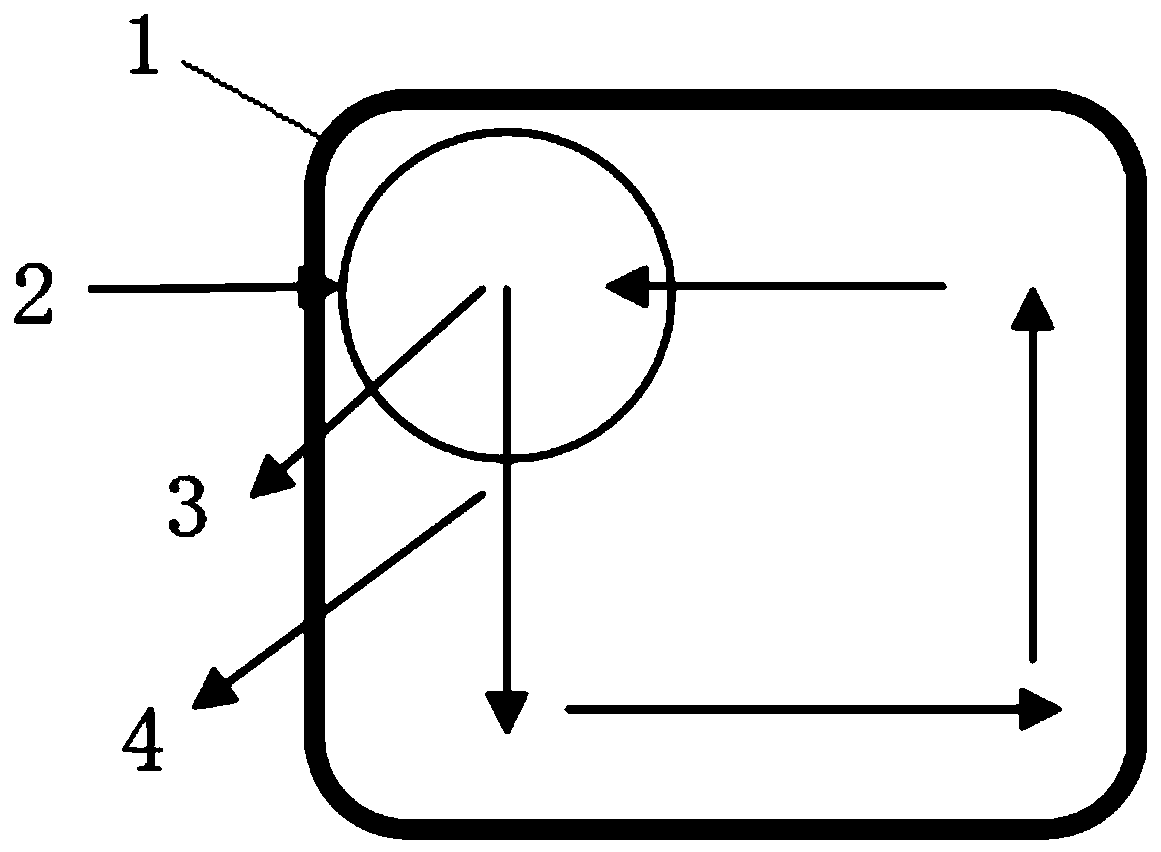

[0021] see Figure 4 , is the processing method of a kind of multi-angle tiny square groove of the present invention, takes the 0.6mm gong cutter to drill the tiny square groove that length and width are 0.7mm as an example, and comprises the following steps:

[0022] Step 1, drill a lower hole 2 with a radius of 0.65mm at the center of the tiny square groove 1;

[0023] Step 2, take the center of the lower knife hole 2 as the starting point, and move the gong knife of the gong groove along the radial direction of a side of the vertical tiny square groove of the lower knife hole to a side position of the tiny square groove (the tiny square groove in the figure the upper side of the square groove), and then move the gong knife clockwise or counterclockwise around the four sides of the tiny square groove for a week, and then return to the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com