Sand sieving device for building construction

A technology for building construction and sand screening, which is used in sieves, solid separation, grids, etc., can solve the problems of clogging of sieve plates, low screening efficiency, poor sand screening effect, etc., to improve quality and improve sand screening efficiency. , the effect of preventing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

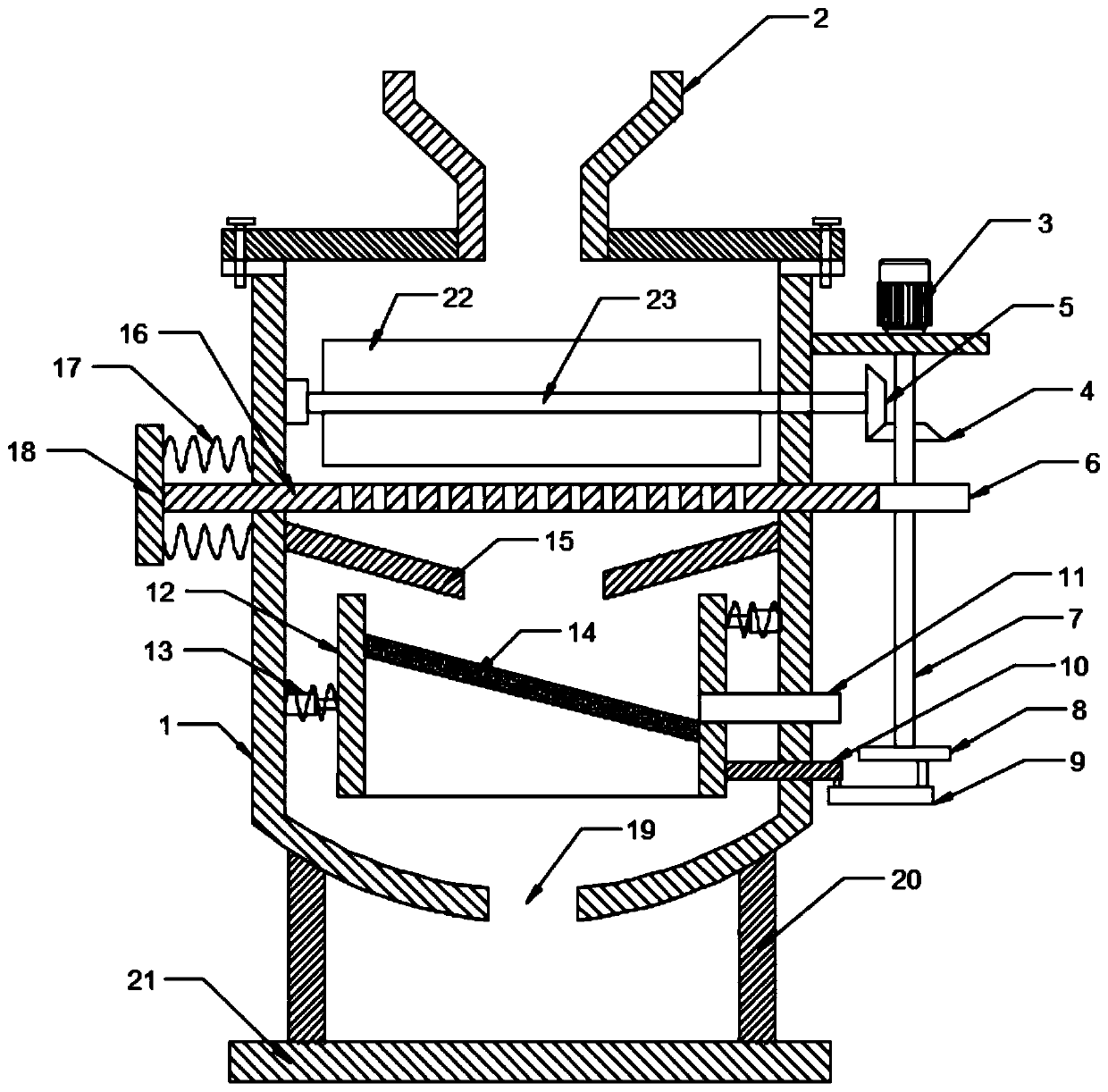

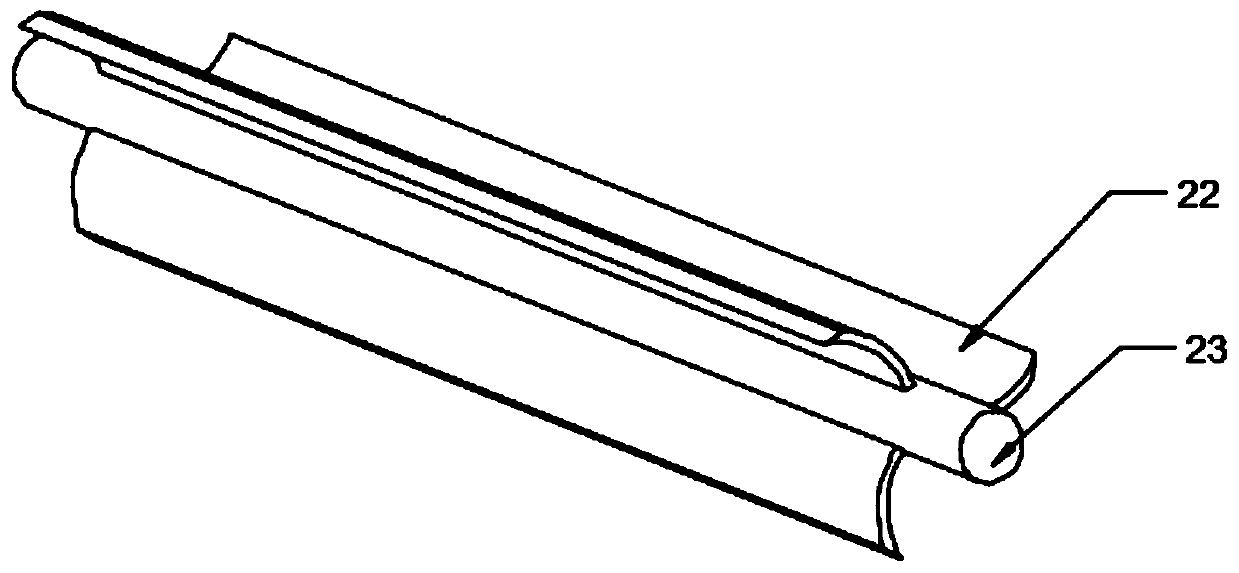

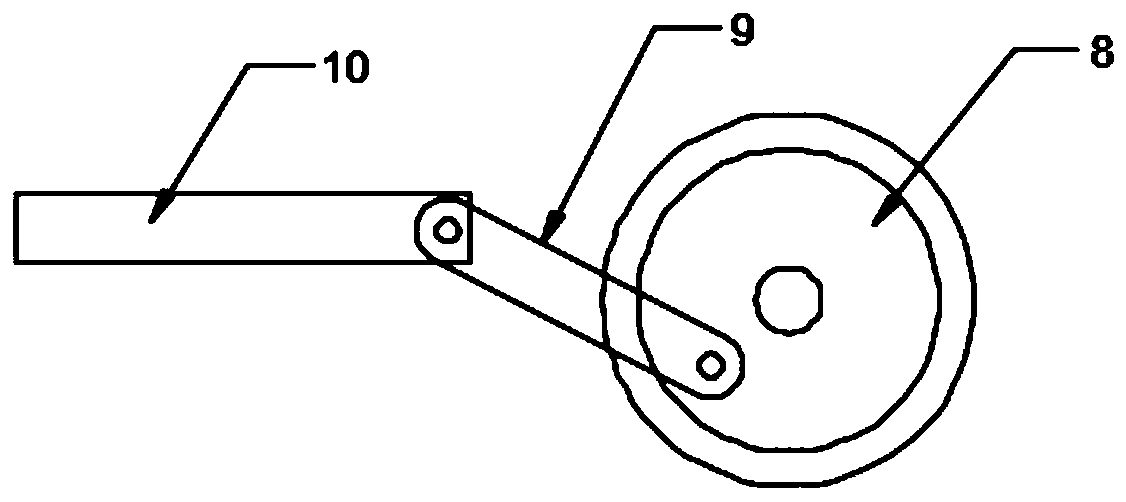

[0024] see Figure 1-3 , a sand screening device for building construction, comprising a screening box 1, a support column 20 and a base 21, the screening box 1 is sequentially provided with a pre-screening sand assembly and a graded sand screening assembly from top to bottom, the pre-screening sand The specific type of the assembly is not limited. In this embodiment, preferably, the pre-screening sand assembly includes a first sieve plate 16, a return spring 17, a fixed plate 18 and a driven shaft 23, and the first sieve plate 16 is movable through the screening box 1 And one end is connected with the fixed plate 18, the return spring 17 is installed between the fixed plate 18 and the outer wall of the screening box 1, the other end of the first sieve plate 16 is connected with a driving member 6 that drives it to move left and right, and the driven shaft 23 is rotated and installed on the Above the first sieve plate 16 and one end extends to the outside of the screening box ...

Embodiment 2

[0033] see Figure 4 , in order to damp the device, this embodiment is further improved on the basis of Embodiment 1, the improvement is that: the support column 20 includes a sleeve rod 2001 and a sleeve 2002, and the sleeve 2002 is fixedly installed on the base 21, The upper end of the sleeve rod 2001 is fixedly connected with the screening box 1, and the lower end is movably sleeved in the sleeve 2002, and a damping spring 2003 is fixedly installed between the sleeve rod 2001 and the sleeve 2002.

[0034] To sum up, the driving component drives the pre-sand screening component and the graded sand screening component to work at the same time, and the scraper 22 in the pre-screwing component rotates to turn the sand accumulated on the first sieve plate 16 to prevent accumulation and improve the sand screening efficiency; The second sieve plate 14 in the grading and sifting sand component realizes grading and sifting sand according to the size of the sand, and improves the qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com