Waste paper winding device for continuous label paper removal

A winding device and waste paper technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problem of unsmooth removal of waste paper peeling and waste paper removal, removal of waste paper breakage, tension In order to improve the winding speed, lift up waste paper smoothly, and prevent cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

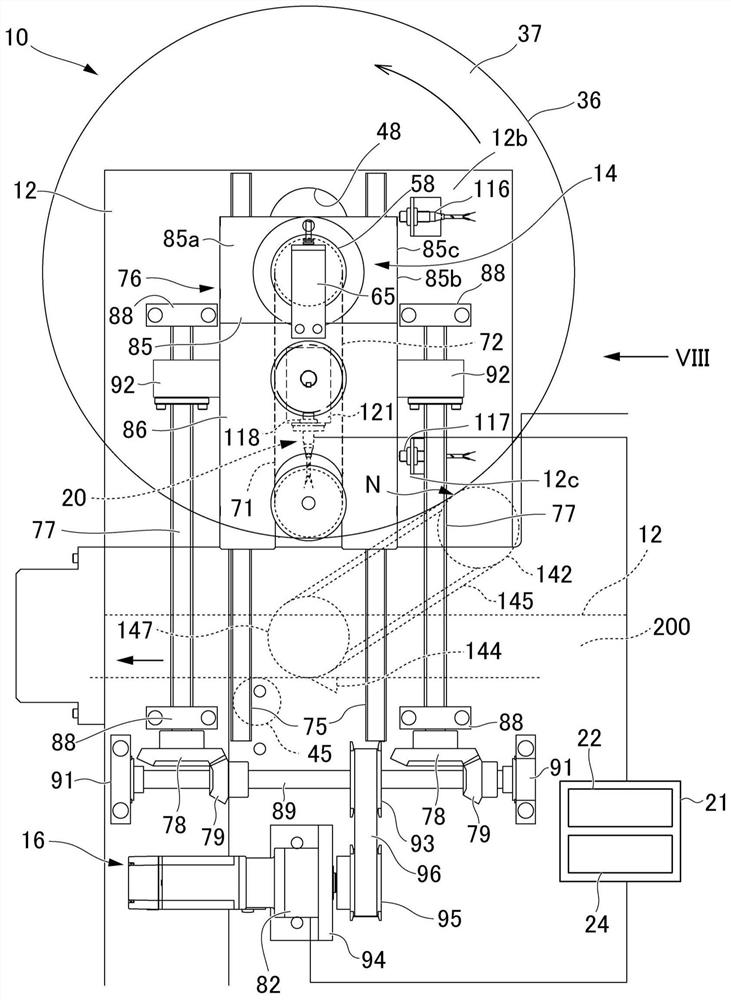

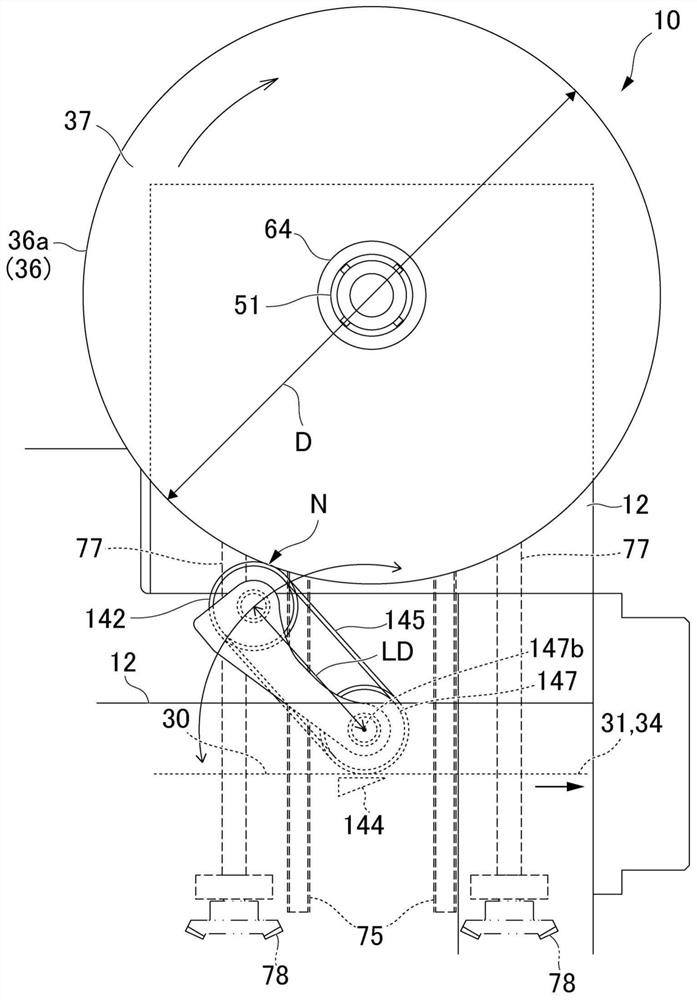

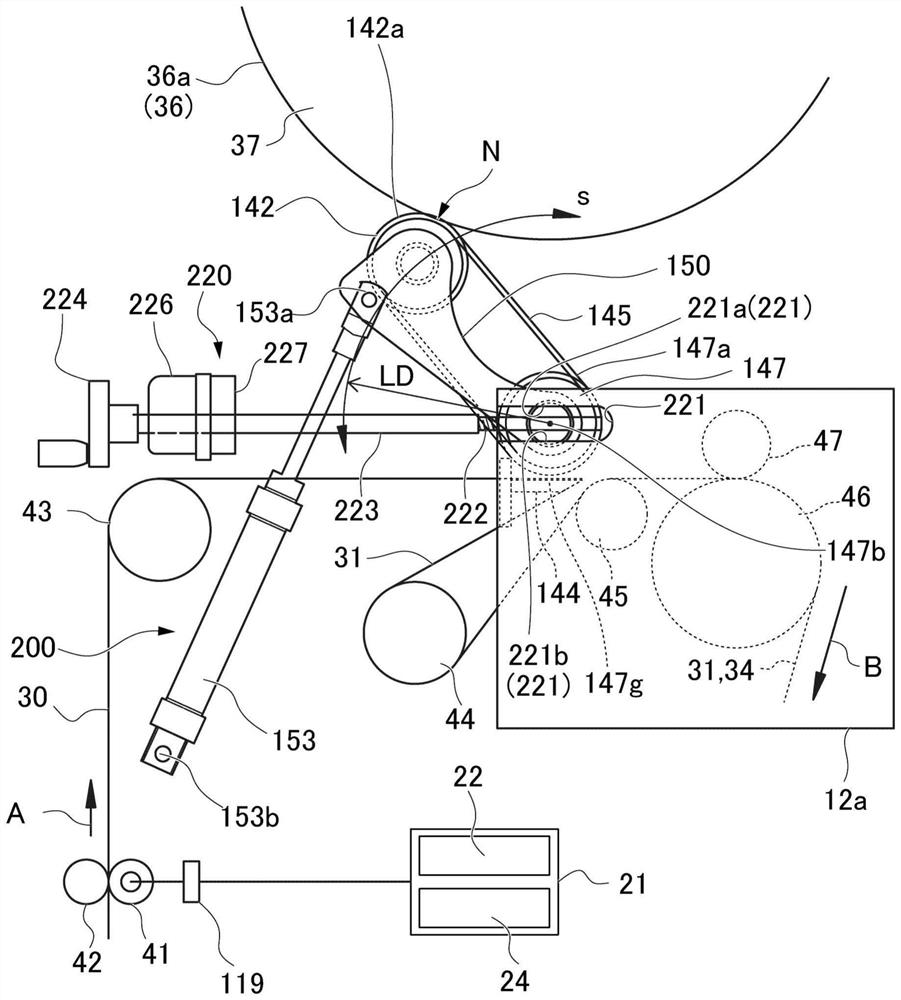

[0045] Hereinafter, an embodiment of the waste paper removal winding device of the present invention will be described based on the drawings. In the drawings, reference numeral 10 is a waste paper rewinding device for continuous label paper.

[0046] Such as Figure 1 ~ Figure 3 As shown, the waste paper winding device 10 for removing continuous label paper in this embodiment includes a frame 12, a winding mechanism 14, a vertical movement mechanism (moving mechanism) 16, a detection device 20, a calculation unit 22, a control unit 24, a waste paper Press the conveyance part 200 and the peeling roller position adjustment part 220 . The calculation unit 22 and the control unit 24 are composed of CPU (Central Processing Unit), RAM (Random Access Memory), ROM (Read Only Memory) and other memories, SSD (Solid State Drive), HDD (Hard Disc Drive) and other storage devices, etc. A type of computer that realizes various functions described below by executing an arithmetic program an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com