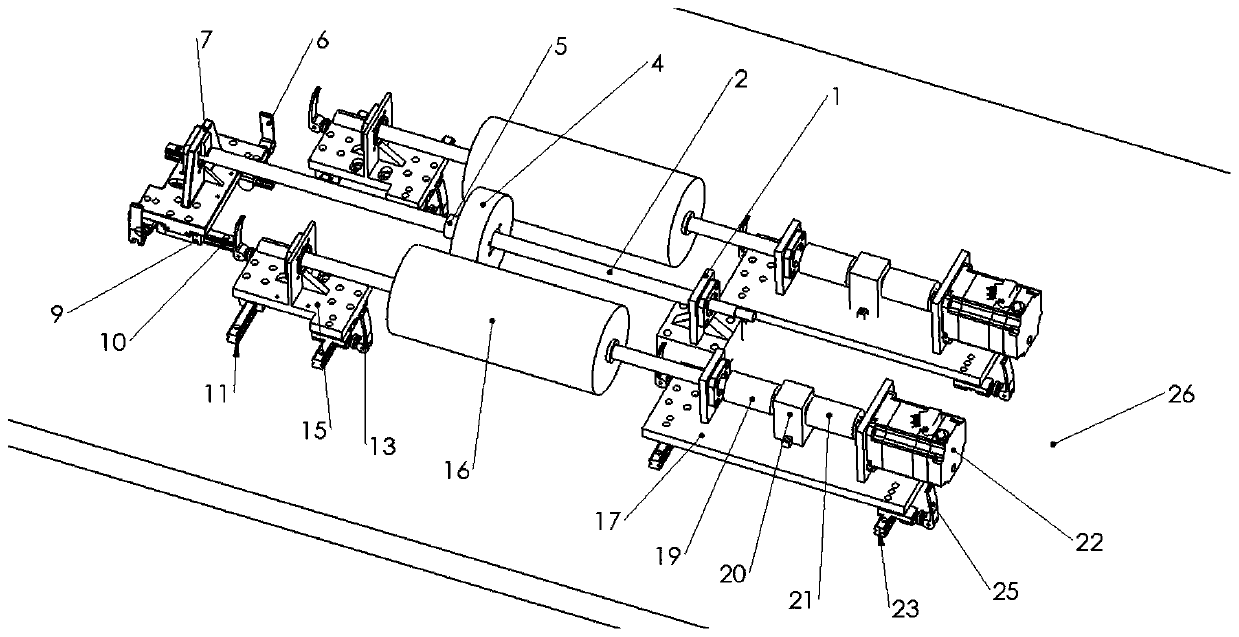

Lead screw reverser frictional resistance torque detection device

A frictional resistance and detection device technology, applied in the direction of measuring devices, force/torque/work measuring instruments, machine/structural parts testing, etc., can solve the problems of lack of versatility, multiple sources of error, complex device structure, etc., and achieve universal Good sex, smooth feel, fine resolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

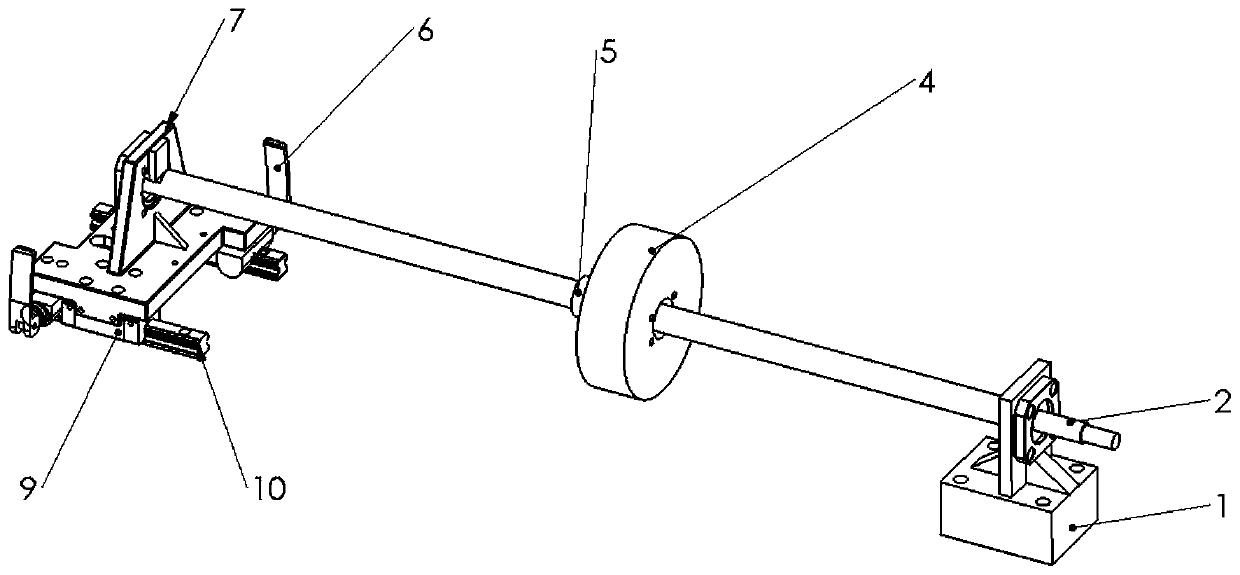

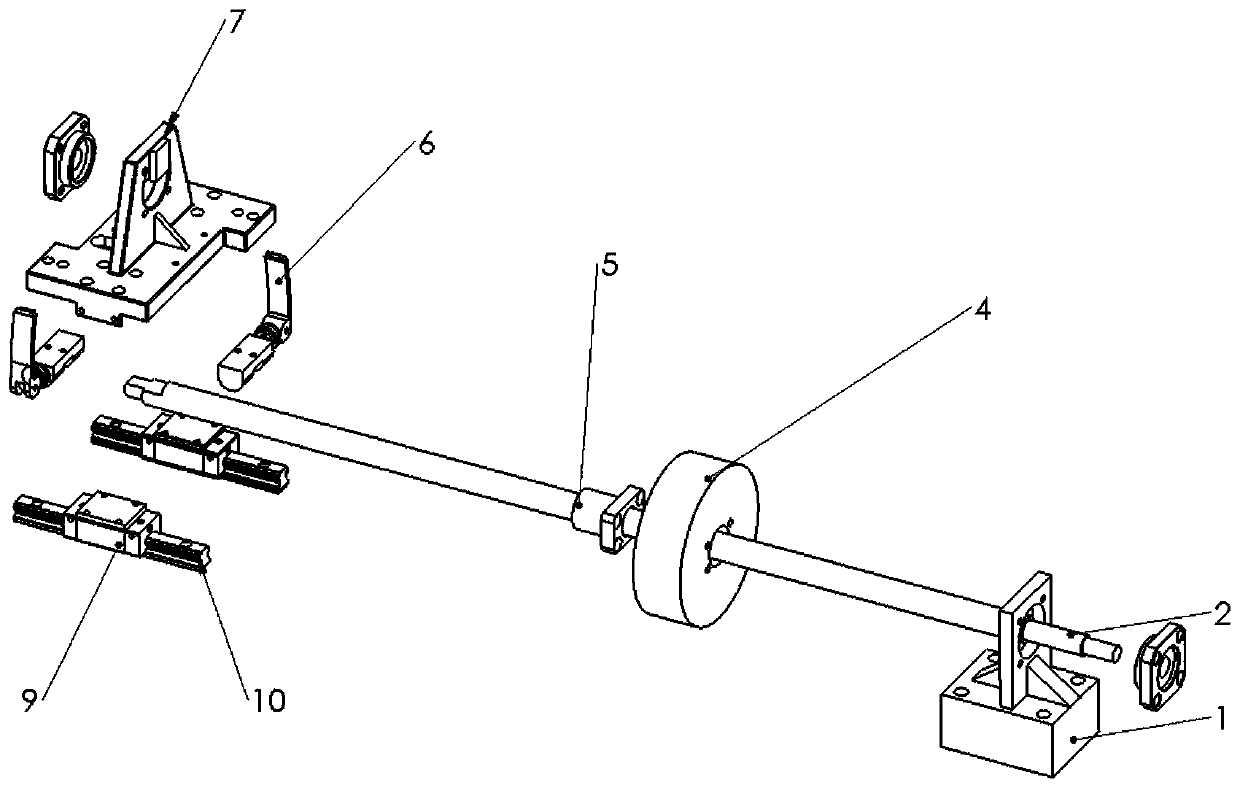

[0022] As an embodiment, the first sliding mechanism includes a first slide block 9 and two parallel first slide rails 10 fixed on the test platform 26 by screws; the sliding direction of the first slide rails 10 is parallel in the axial direction of the lead screw 2; the first slider 8 cooperates with the first slide rail 10; the first bracket 7 is fixed on the first slider 8; A clamper 6 is used for fixing the sliding position of the first slider 8 and the two first guide rails 10 .

[0023] The friction wheel mechanism includes a second sliding mechanism, a third sliding mechanism, a third bracket 15, a fourth bracket 17, a friction wheel 16, a motor 22, a first coupling 21, a torque sensor 20, and a second coupling 19 ;

[0024] The third support 15 is fixed on the second sliding mechanism, and the fourth support 17 is fixed on the third sliding mechanism; the sliding directions of the second sliding mechanism and the third sliding mechanism are all perpendicular to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com