Semiconductor processing equipment

A technology for processing equipment and semiconductors, which is applied in the fields of semiconductor/solid-state device manufacturing, combined devices, electrical components, etc., and can solve problems affecting semiconductor wafer manufacturing processes and the overall yield decline of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

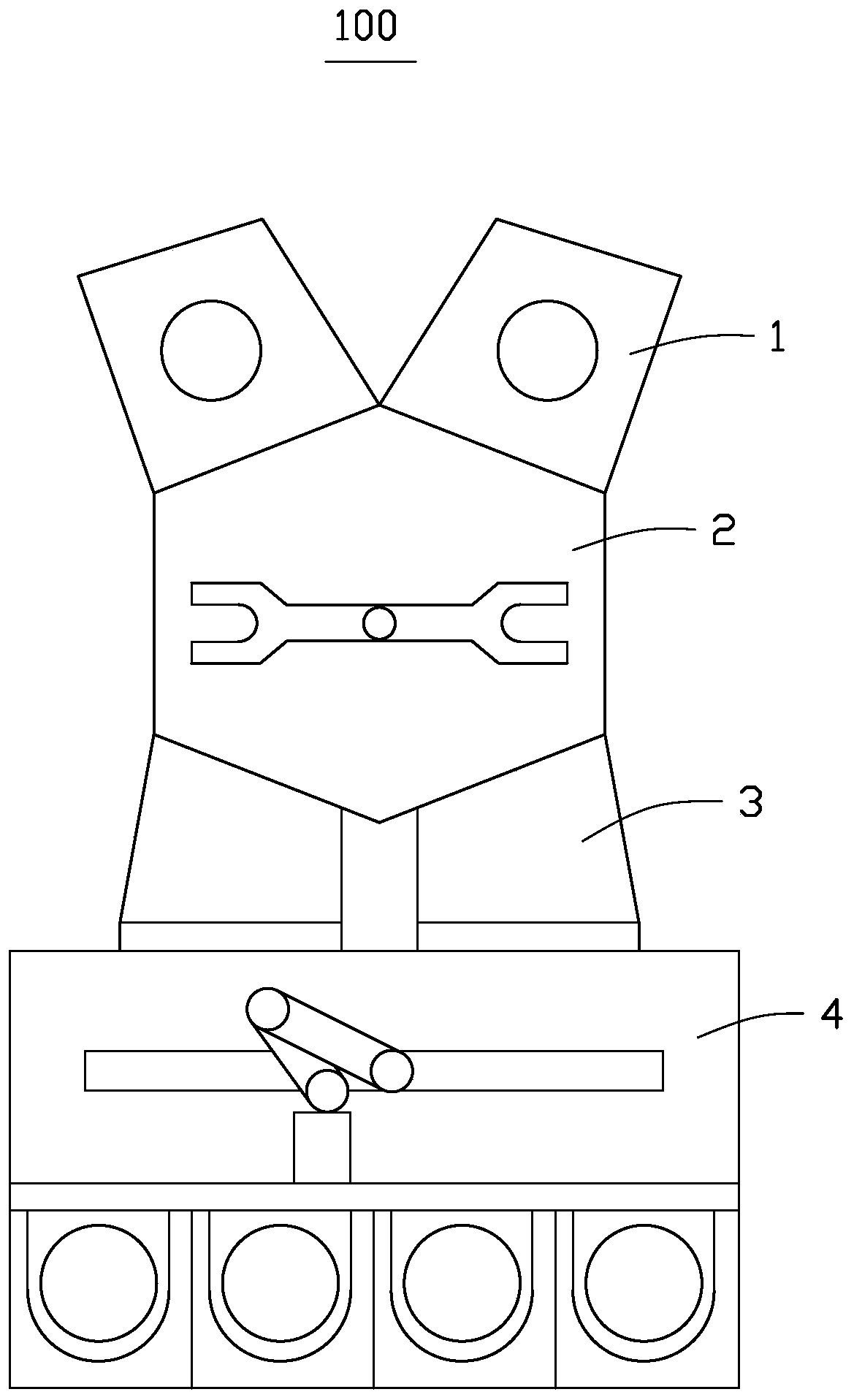

[0031] see figure 1 and figure 2 , in the first embodiment, the semiconductor processing equipment 100 includes a plurality of processing chambers 1 , a transfer chamber 2 , at least one preload chamber 3 , a front-end module 4 and a gas purification device 5 . The multiple processing chambers 1 are used to etch semiconductor wafers, the transfer chamber 2 is used to send the semiconductor wafers into different processing chambers 1, and the pre-loading chamber 3 is used to connect the transfer chambers 2 As well as the front-end module 4 of the equipment, the gas purification device 5 is arranged in the pre-loading chamber 3 . The equipment front-end module 4 is used for sending unprocessed semiconductor wafers into the semiconductor processing equipment 100 , or for sending processed semiconductor wafers out of the semiconductor processing equipment 100 .

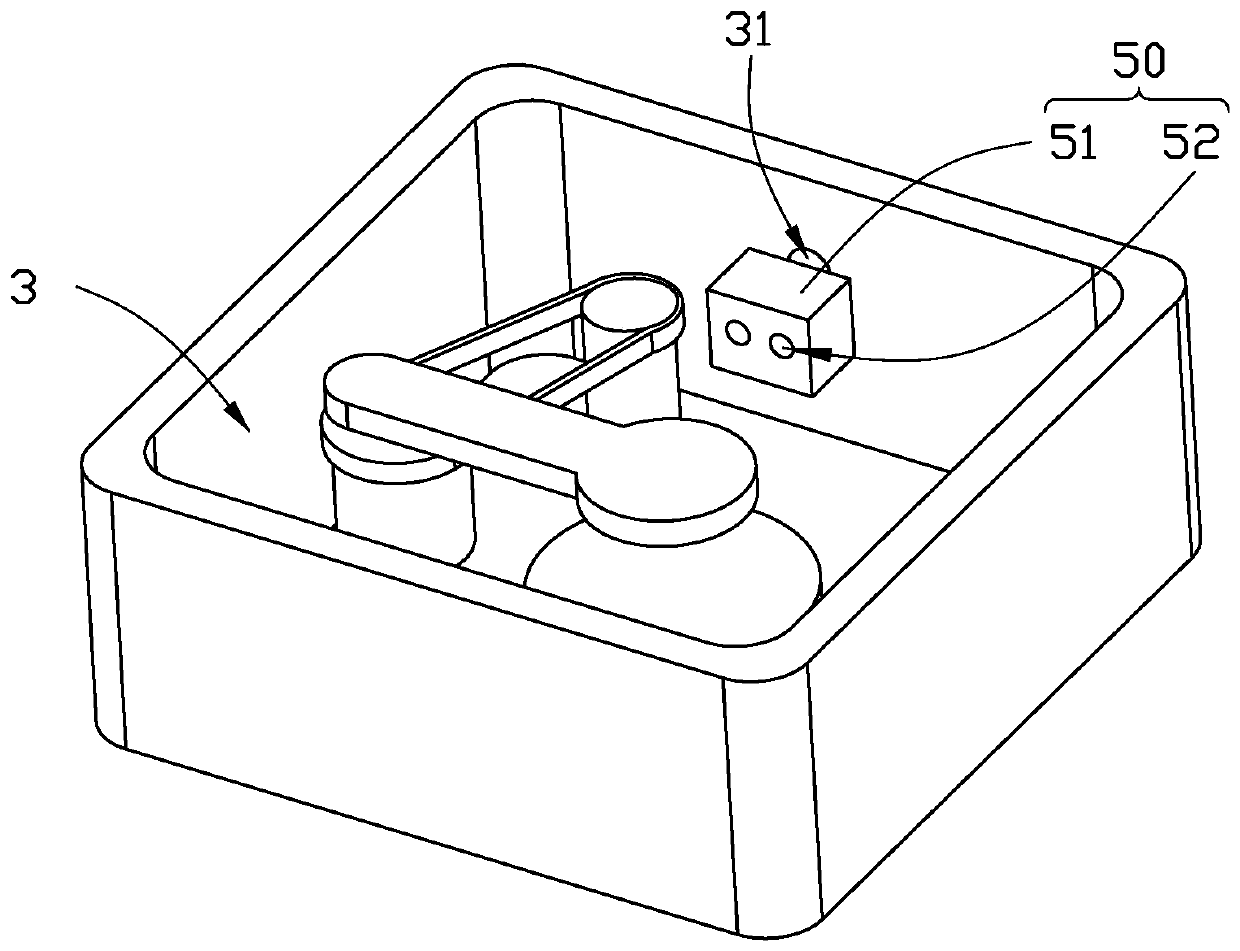

[0032] Further, the pre-loading chamber 3 is connected to a vent pipe 31, and the gas purification device 5 is arran...

no. 2 example

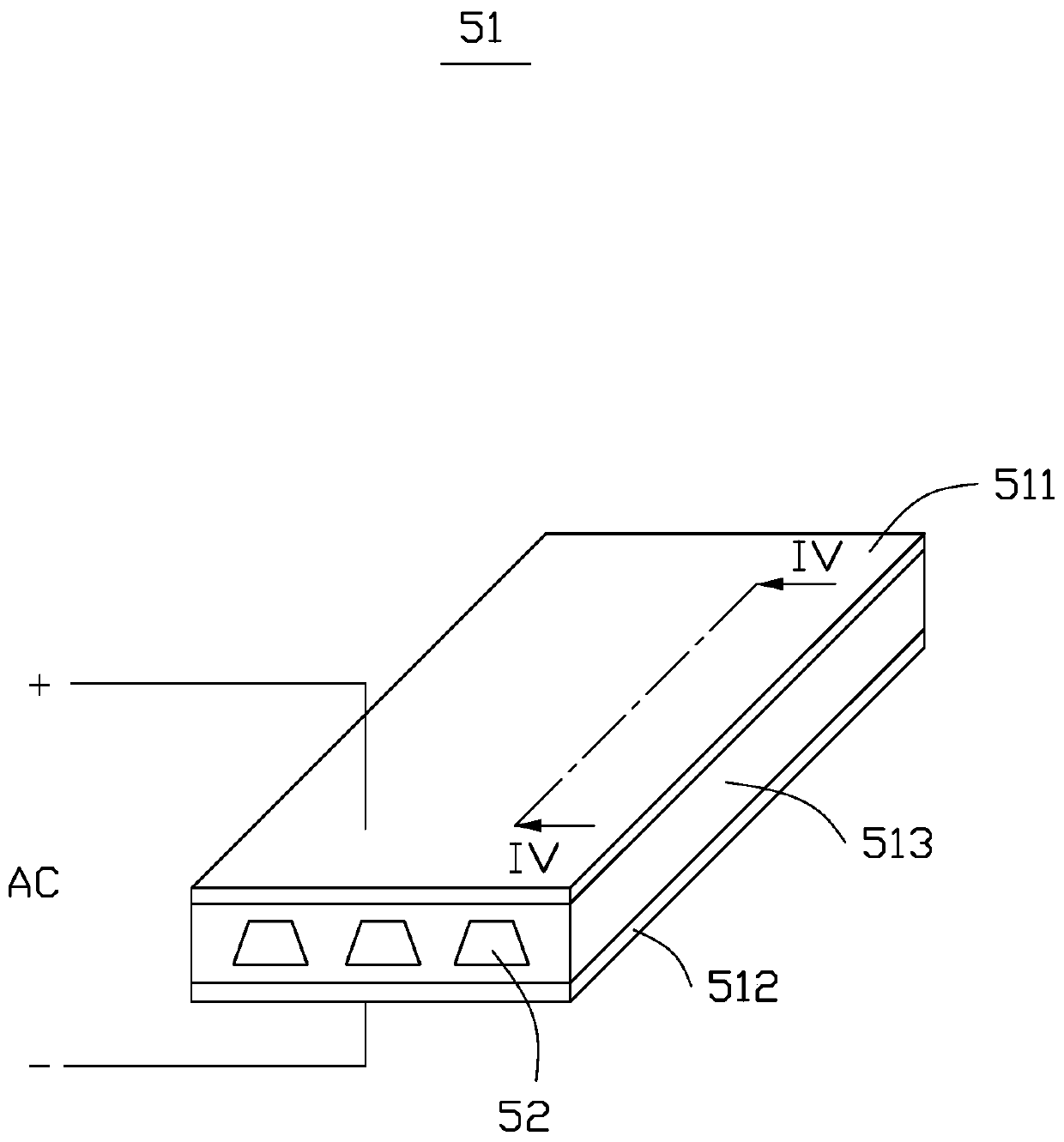

[0039] see figure 1 , figure 2 and Image 6 , the semiconductor processing equipment 100 includes a plurality of processing chambers 1 , a transfer chamber 2 , at least one pre-load chamber 3 , a front-end module 4 and a gas purification device 5 . The multiple processing chambers 1 are used to etch semiconductor wafers, the transfer chamber 2 is used to send the semiconductor wafers into different processing chambers 1, and the pre-loading chamber 3 is used to connect the transfer chambers 2 As well as the front-end module 4 of the equipment, the gas purification device 5 is arranged in the pre-loading chamber 3 . The pre-loading chamber 3 is connected to a vent pipe 31 , and the gas purification device 5 is arranged at the inlet end of the vent pipe 31 , and the gas inlet end is located on the inner cavity side wall of the pre-load chamber 3 . The gas purification device 5 includes a plasma generator 51 and an airflow channel 52 , the airflow channel 52 runs through the ...

no. 3 example

[0043] see Figure 7 The semiconductor processing equipment of the third embodiment is substantially the same as that of the semiconductor processing equipment of the first embodiment, the difference is that the semiconductor processing equipment of the third embodiment further includes a filter 7 . The filter 7 is arranged at the intake end of the vacuum pump 32 to prevent the pollution particles from entering the vacuum pump 32 and ensure the stable and safe operation of the vacuum pump 32 .

[0044] Further, a third detector 8 is also arranged in the inner cavity of the pre-loading chamber 3 , and the third detector 8 is used to detect the particle concentration in the pre-loading chamber 3 . A valve 311 is provided in the ventilation pipe 31 , and the valve 311 is electrically connected to the third detector 8 . When the detection value of the third detector 8 is lower than a preset value, it means that the gas environment in the pre-loading chamber 3 has reached the clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com