Rotary tillage flattening ditcher

A ditching machine and horizontal opening technology, which is applied in the direction of excavation/covering ditches, planting methods, agricultural machinery and tools, etc., can solve the problems of only ditches and broken soil, but cannot be flattened, and fallen into, to achieve The effect of wide application range, improving efficiency and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

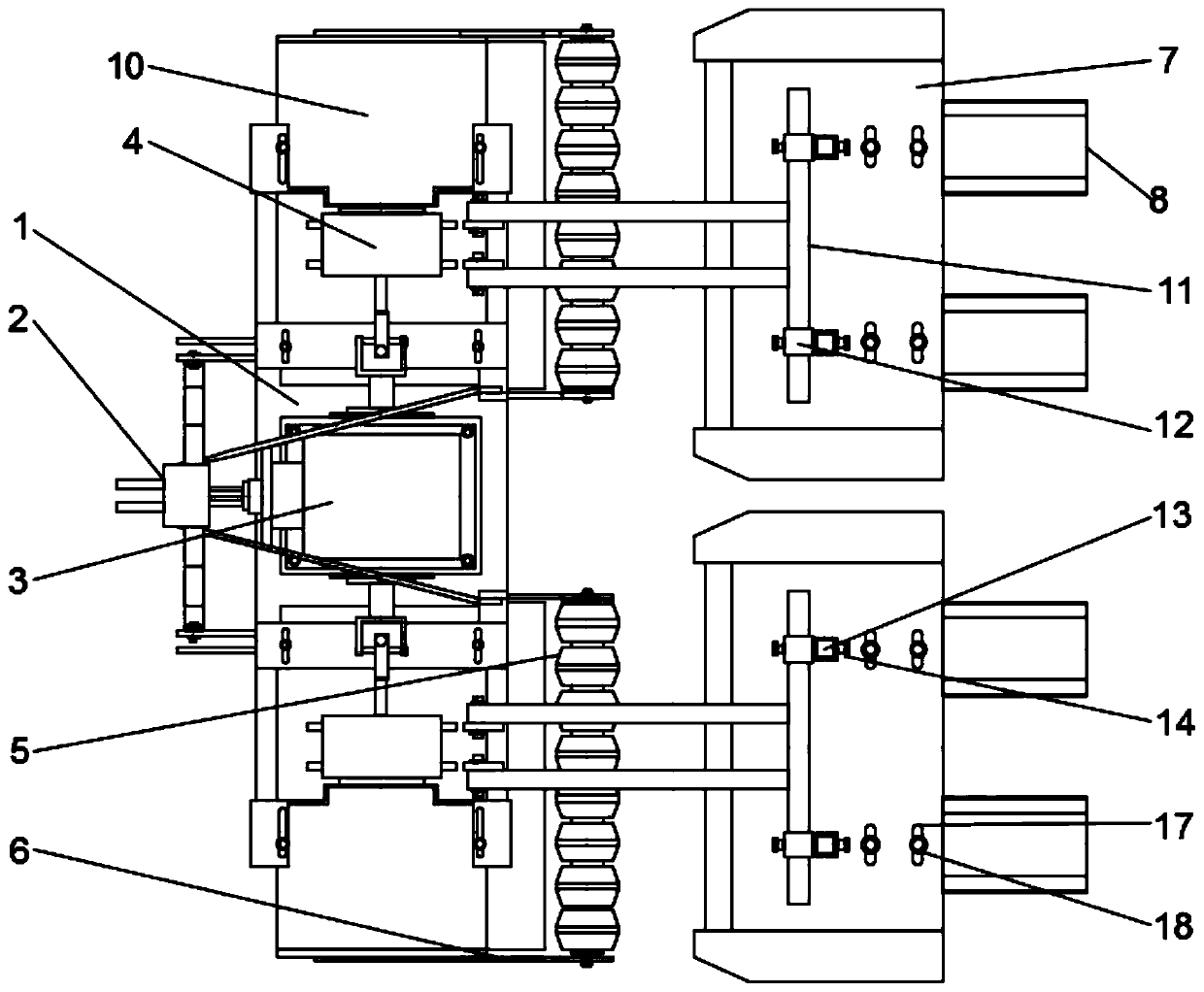

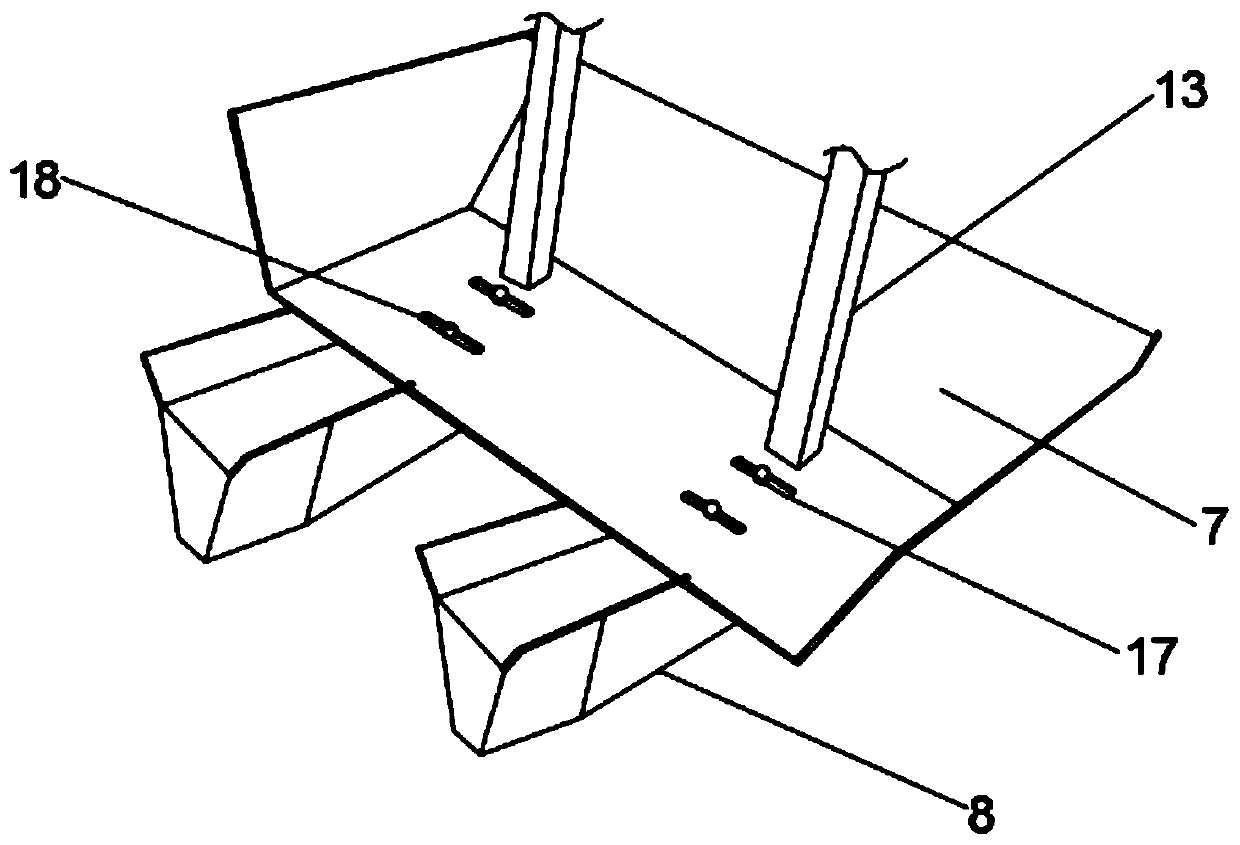

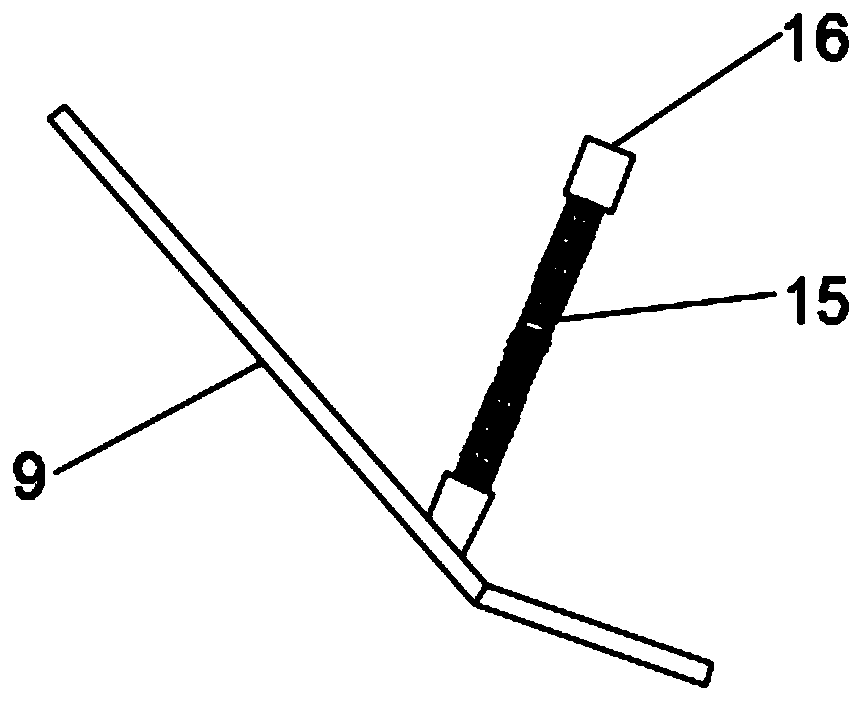

[0022] Such as Figure 1-3 As shown, a rotary tillage leveling ditching machine includes a frame 1, a traction frame 2 is installed on the top of the frame 1, a hydraulic cylinder is arranged on the traction frame 2, and a hydraulic cylinder is installed on the top of the frame 1. There is a fertilizer box, and the two ends of the frame 1 are respectively movably connected with rotary tillage devices, and soil separators are installed on the outsides of the two rotary tiller devices. A pressing plate 9 is arranged between the two rotary tillage devices, and the pressing plate 9 is installed under the frame 1 through a shock absorbing assembly. The shock absorbing device includes a spring 15 and a mount 16, and the spring Both ends of 15 are respectively fixed on the pressing plate 9 and the frame 1 through the mounting base 16 .

[0023] The top of the frame 1 is installed with a transmission device 3 for driving the rotary tiller, the transmission device is movably connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com