Ammonia spraying optimization control method and system for SCR flue gas denitrification device

A technology for optimizing control and control systems, applied in the direction of control/regulation systems, flow control using electrical devices, chemical instruments and methods, etc., can solve the uneven velocity field, the influence of ammonia/nitrogen molar ratio, and the increase of ammonia escape from the reactor outlet. and other problems to achieve the effect of accurate and comprehensive representativeness of measurement data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

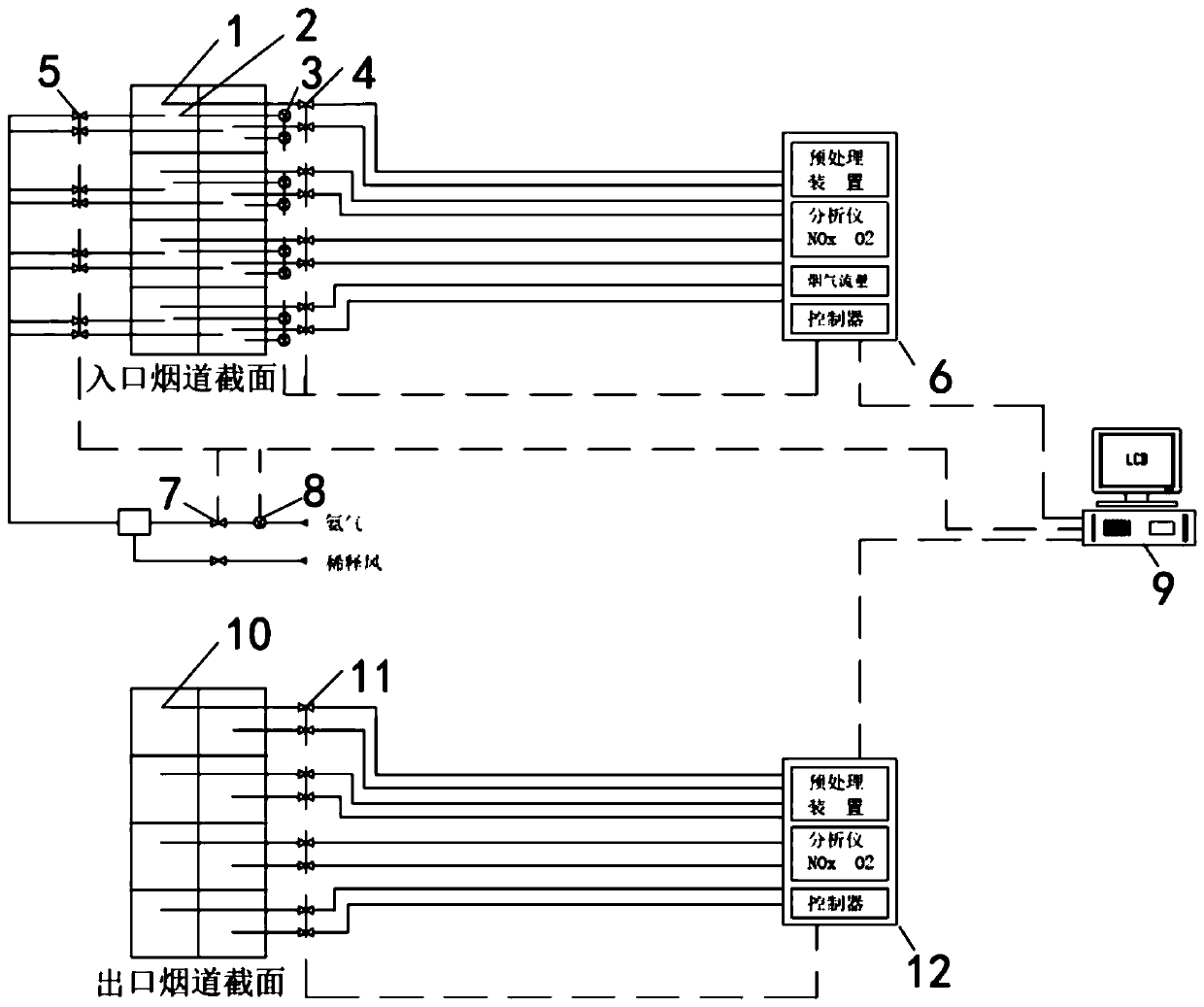

[0045] see figure 1 An ammonia injection optimization control system for an SCR flue gas denitrification device provided in Embodiment 1 of the present invention is characterized in that the flue cross section is meshed based on the grid method to obtain the sampling area of the flue cross section. For inlet flue NO x Concentration zone measurement and flue gas flow zone measurement, outlet flue NO x Concentration zone measurement, and ammonia injection in corresponding zones of the inlet flue, the system includes: inlet flue gas sampling device 1, inlet flue gas flow pressure measuring device 2, transmitter 3, inlet switching valve 4, inlet flue Ammonia injection branch valve 5, inlet flue ammonia injection main valve 7, inlet flue ammonia injection main pipe flowmeter 8, inlet flue gas analysis and control device 6, outlet flue gas sampling device 10, outlet switching valve 11 , outlet flue gas analysis and control device 12, DCS control system 9, wherein,

[0046] The ...

Embodiment 2

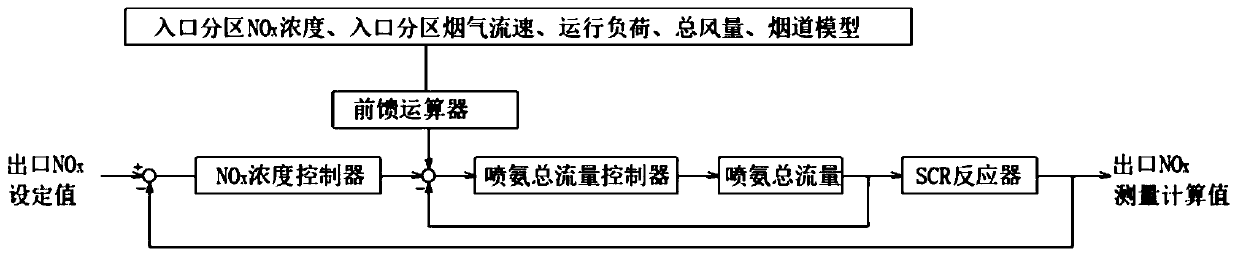

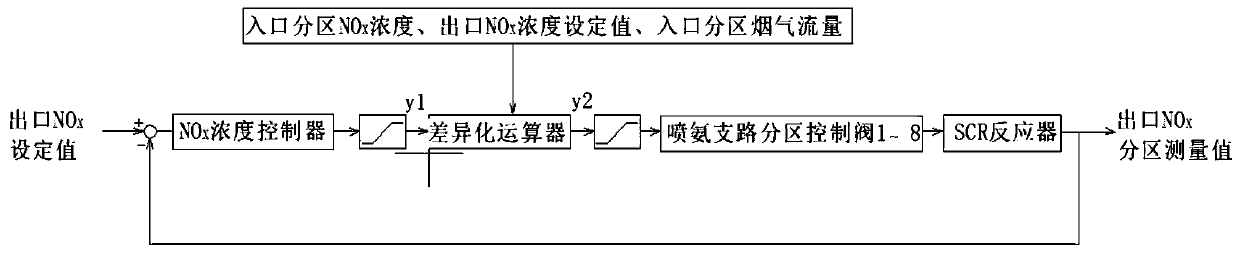

[0075] Corresponding to the ammonia injection optimization control system of the SCR flue gas denitrification device disclosed in the first embodiment of the present invention, the second embodiment of the present invention also provides a method for the optimization control system of the ammonia injection of the SCR flue gas denitrification device, see Figure 4 , the method includes:

[0076] S11. Carry out grid division on the inlet and outlet flue cross sections based on the grid method to obtain multiple grid sampling areas;

[0077] S12. Pretreat the flue gas sampled from the inlet flue, and take turns to measure the flue gas, and obtain the NO of the inlet flue. x Concentration partition measurement value;

[0078] S13. Simultaneously measure the flue gas flow in the inlet flue in different zones;

[0079] S14. Pretreat the flue gas sampled from the outlet flue, and take turns to measure the flue gas, and obtain the NO of the outlet flue. x Concentration partition me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com