A flue based on grid method x Concentration measurement system and method

A grid method and flue technology, applied in the field of flue gas denitrification, can solve the problems of lack of ammonia amount, uneven distribution of concentration field, and inability of all ammonia to participate in the reaction, so as to reduce ammonia escape rate and NOx concentration, and achieve good economic benefits. and environmental benefits, the effect of reducing ammonia consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

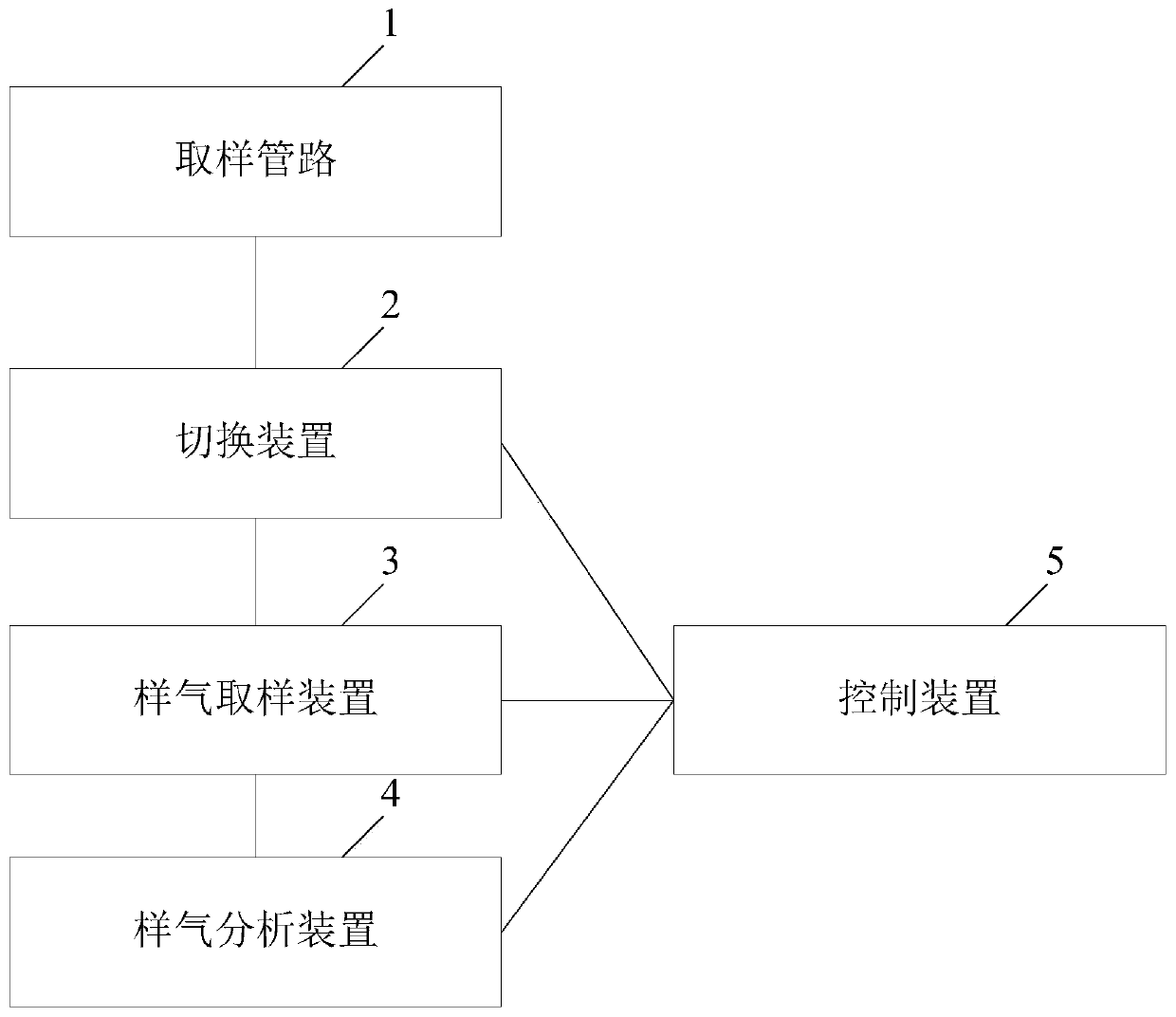

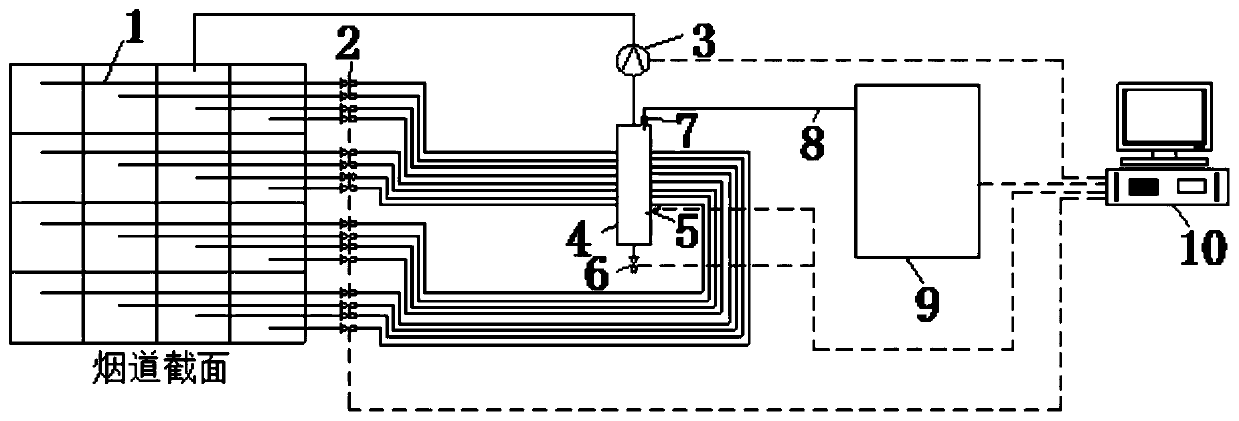

[0039] see figure 1 A flue NOx concentration measurement system based on the grid method provided for Embodiment 1 of the present invention is characterized in that the system includes: a sampling pipeline 1, a switching device 2, a sample gas sampling device 3, a sample gas analysis device 4 and control device 5, wherein,

[0040] Each sampling pipeline 1 corresponds to a grid sampling area, and the grid sampling area is a flue cross-section sampling area obtained by meshing the flue cross-section;

[0041] The switching device 2 is used to receive a control command from the control device to select the corresponding sampling pipeline 1;

[0042] The sample gas sampling device 3 is used to extract the sample gas from the selected sampling pipeline, and transport the extracted sample gas to the sample gas analysis device 4;

[0043]The sample gas analysis device 4 is configured to analyze the extracted sample gas to obtain sample gas analysis data, and send the sample gas an...

Embodiment 2

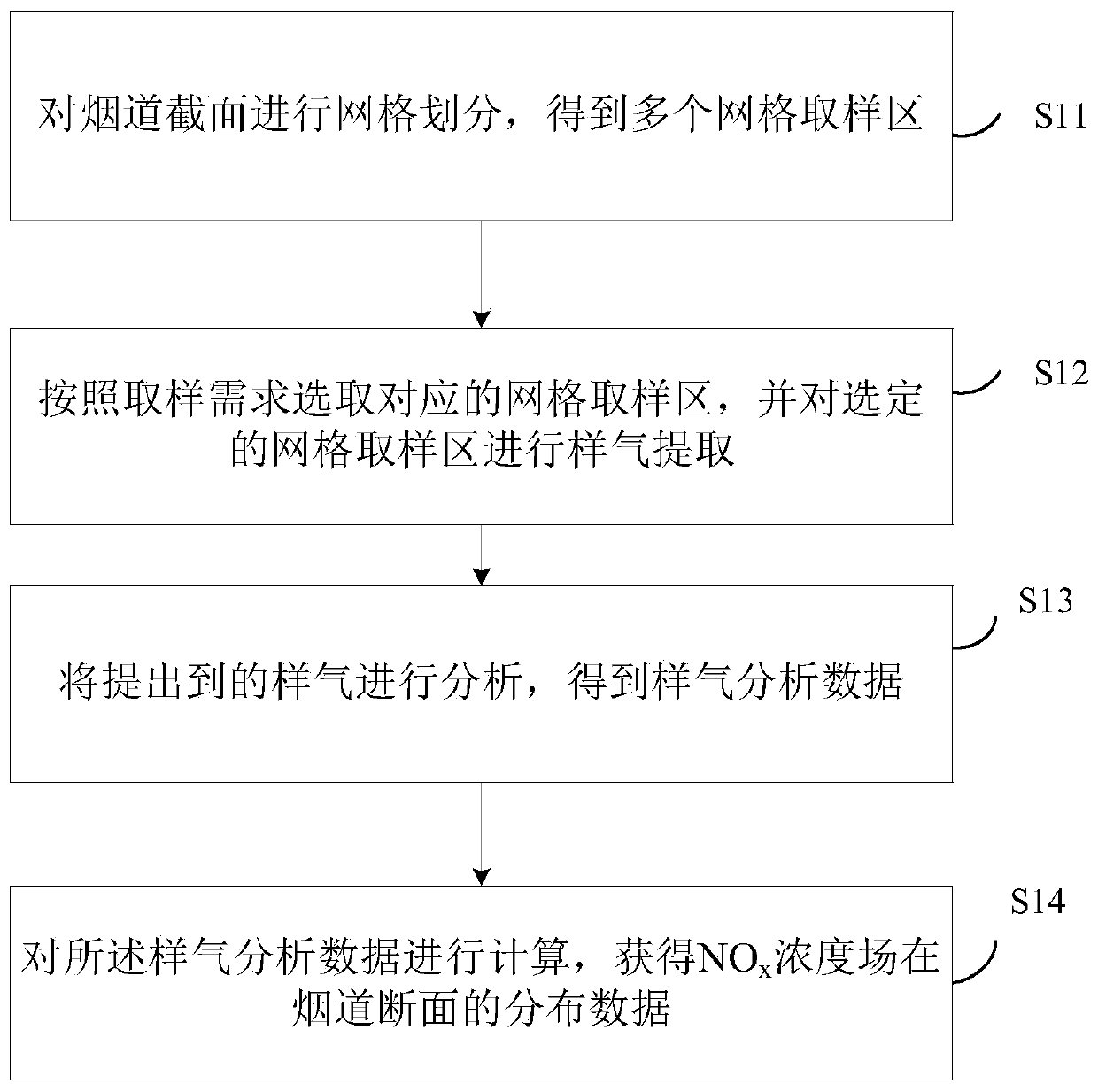

[0070] With the flue NO based on the grid method disclosed in Embodiment 1 of the present invention x Corresponding to the concentration measurement system, Embodiment 2 of the present invention also provides a grid-based flue NO x Concentration measurement method, see Figure 3, the method includes:

[0071] S11. Carrying out grid division on the cross section of the flue to obtain multiple grid sampling areas;

[0072] S12. Select the corresponding grid sampling area according to the sampling requirements, and extract the sample gas from the selected grid sampling area;

[0073] S13. Analyzing the proposed sample gas to obtain sample gas analysis data;

[0074] S14. Calculate the sample gas analysis data to obtain NO x The distribution data of the concentration field in the flue section.

[0075] Correspondingly, before analyzing the proposed sample gas and obtaining the sample gas analysis data, the method also includes:

[0076] The extracted sample gas is dedusted and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com