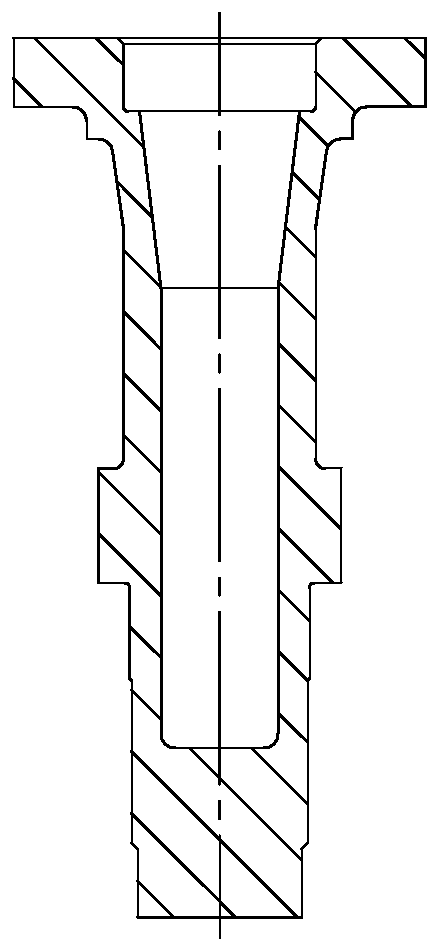

Vertical forging process of double-shaft-coupling tooth blank with deep blind holes

A double-coupling, deep blind hole technology, applied in the field of forging technology, can solve the problems of increasing the cost of a trimming die, not being able to forge deep blind holes, and long process flow, so as to facilitate plastic deformation, avoid folding or Interlayer, quality-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0038] A vertical forging process for double-coupling gear blanks with deep blind holes, comprising the following steps:

[0039] Step 1. Precise blanking; after passing the inspection, the bar is blanked with a band saw or circular saw. The sawing seam is required to be smooth, and the blank is precisely blanked according to the weight of the forged blank. The blanking error must not exceed 1%;

[0040] Step 2. Heating to the forging temperature; putting the billet into an induction heating furnace or a gas heating furnace, heating to the forging temperature and then releasing it from the furnace;

[0041] Step three, aggregate;

[0042] Step four, pre-forging;

[0043] Step five, final forging.

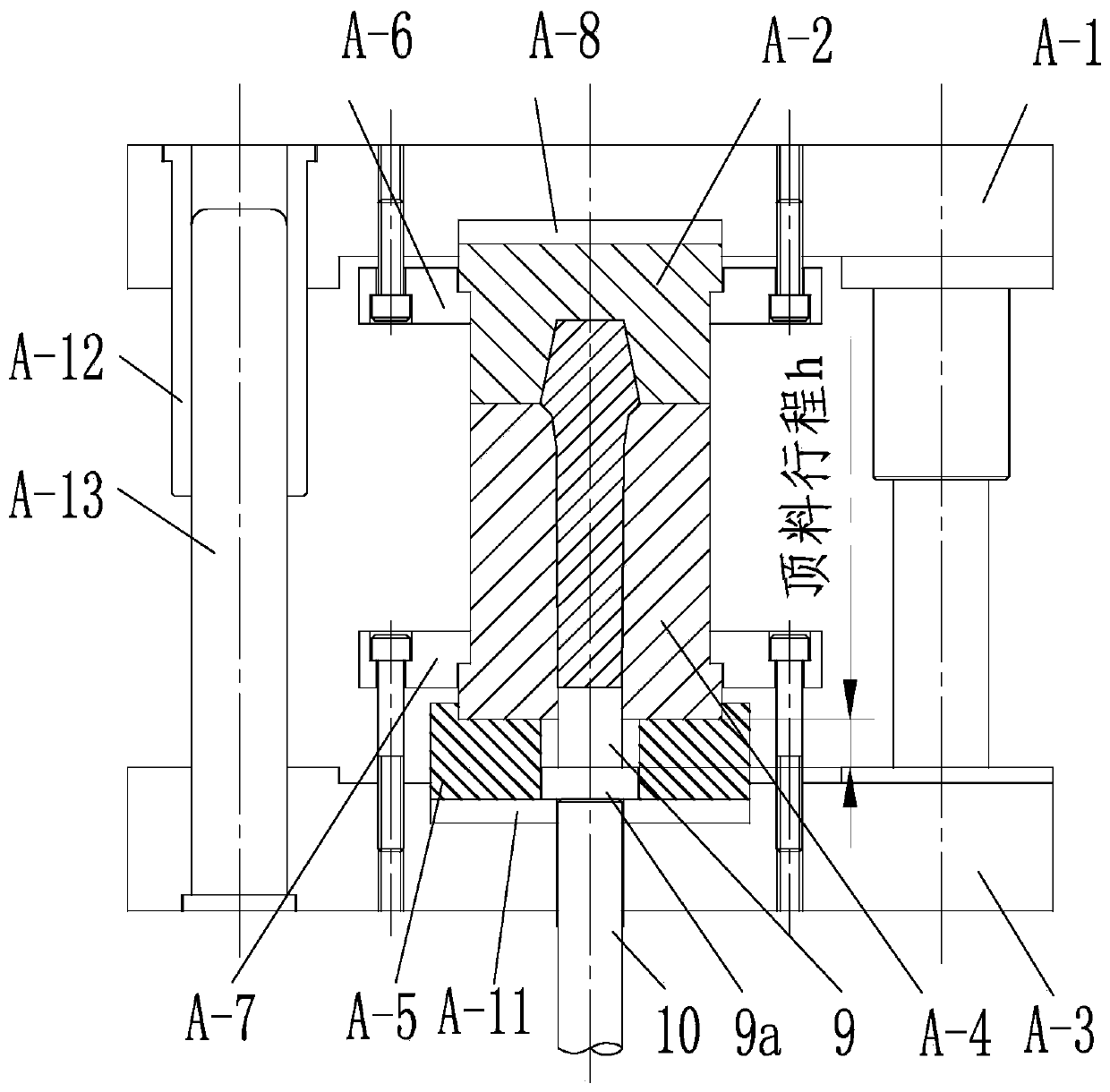

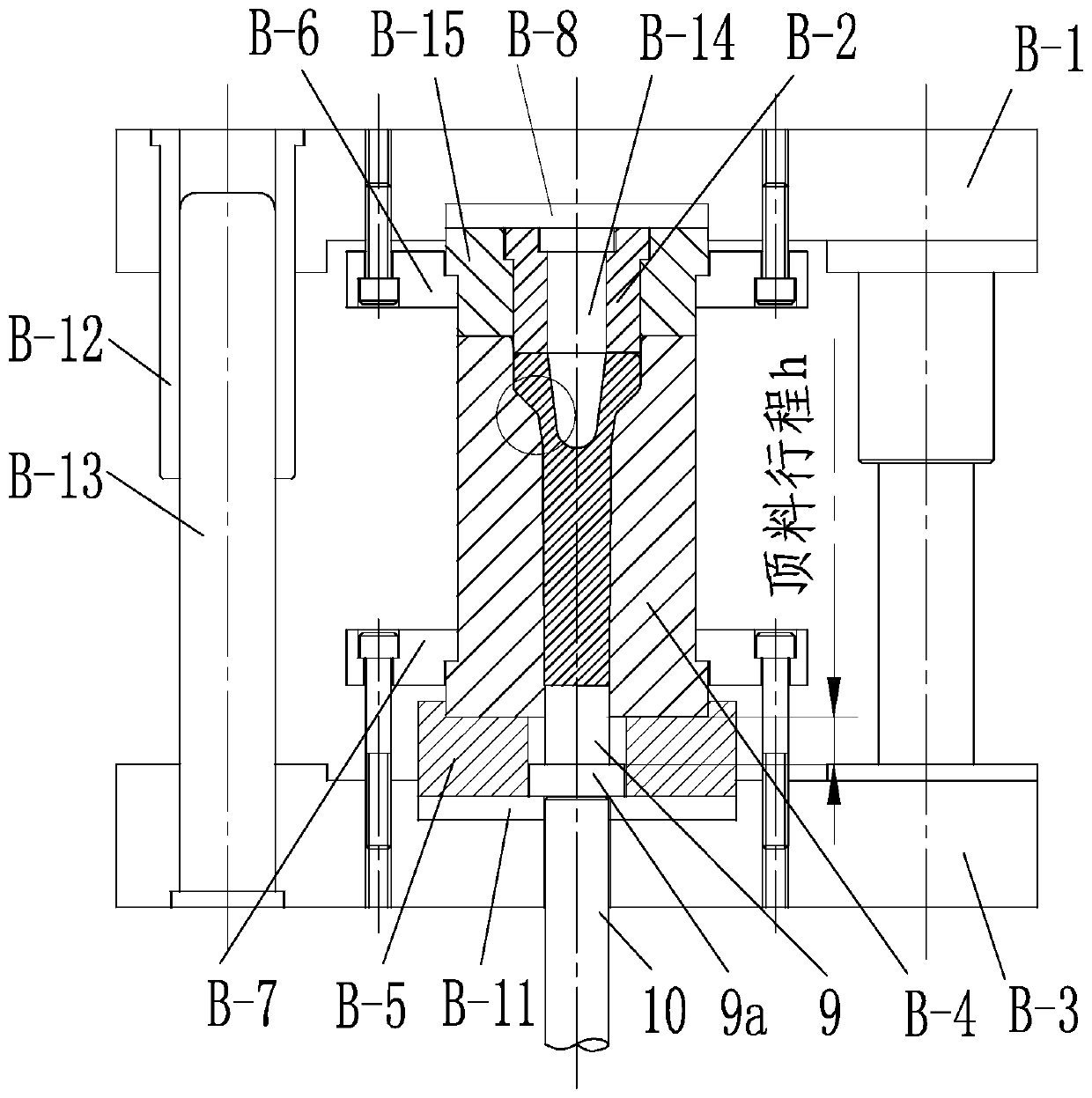

[0044] like figure 2 As shown, the aggregate mold used in the aggregate process is mainly composed of the aggregate mold upper template A-1, the aggregate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com