Placed machining frame equipment for re-machining for ceramic with high-strength structure

A reprocessing and high-strength technology, which is applied in the field of ceramic processing, can solve the problems of low cutting quality of the adjustable structure, the difficulty of fast fixing multiple pieces, the inability to realize the angle adjustment and fast locking of the fixed frame, and achieve clamping and fixing. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

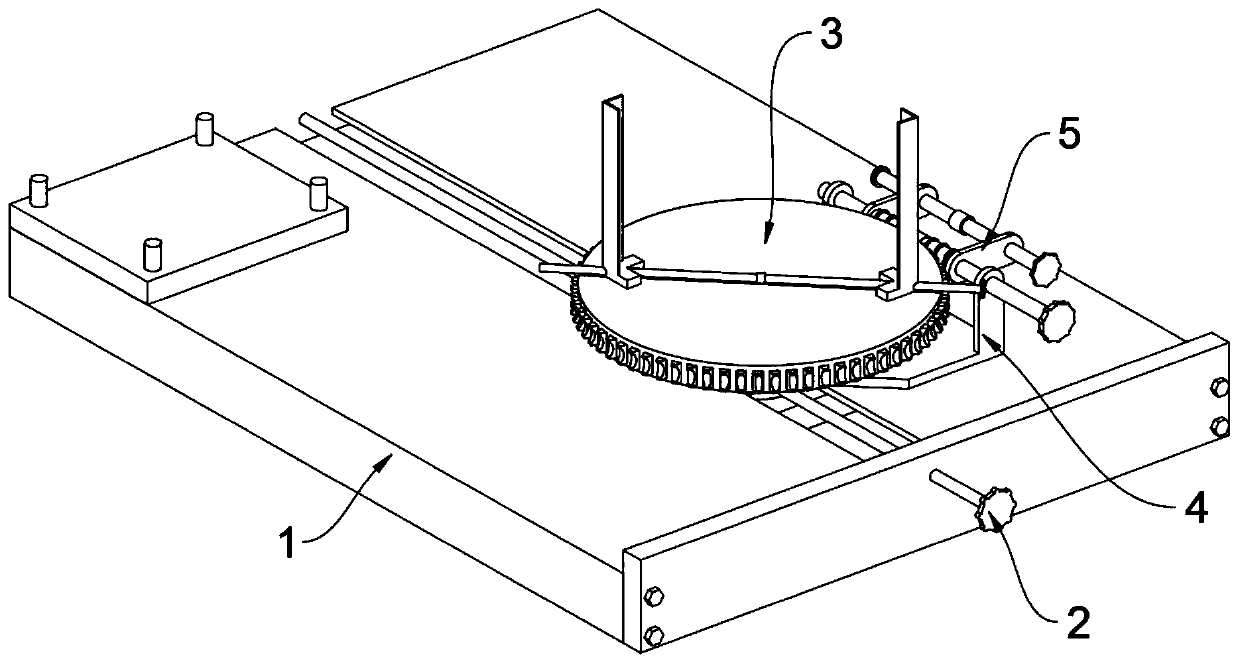

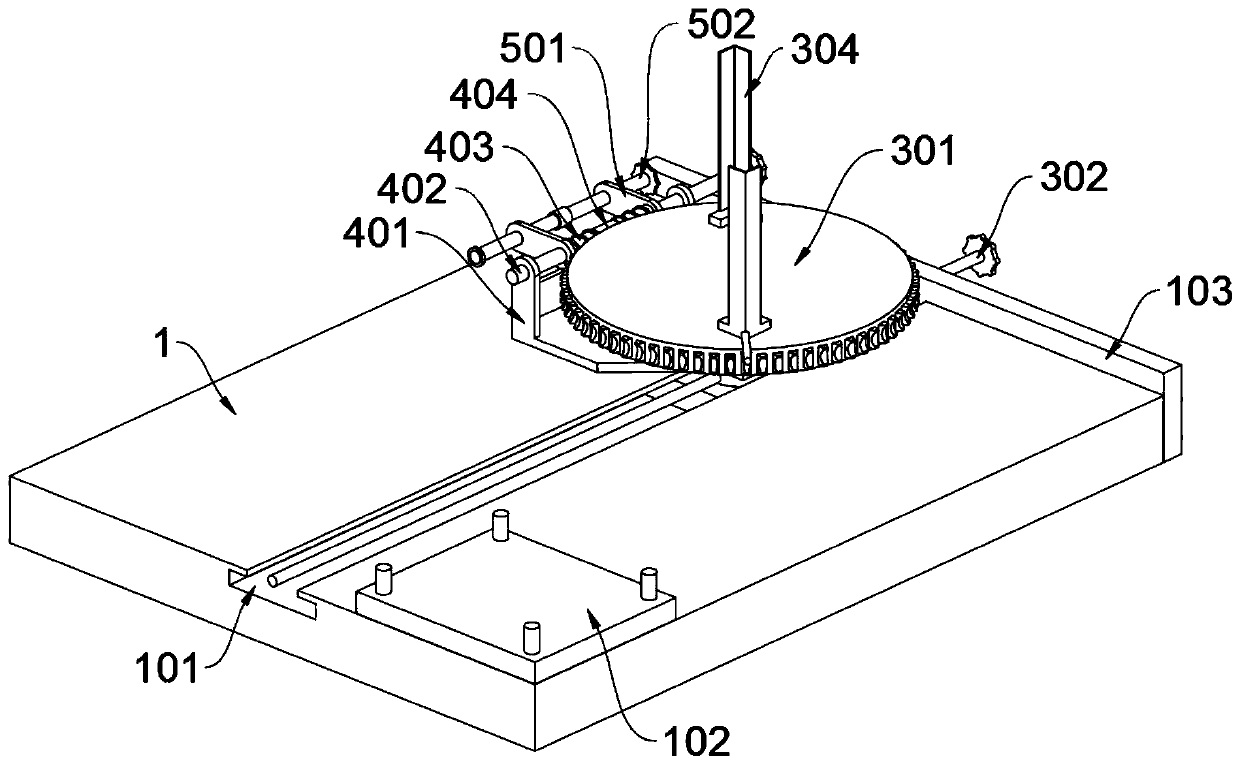

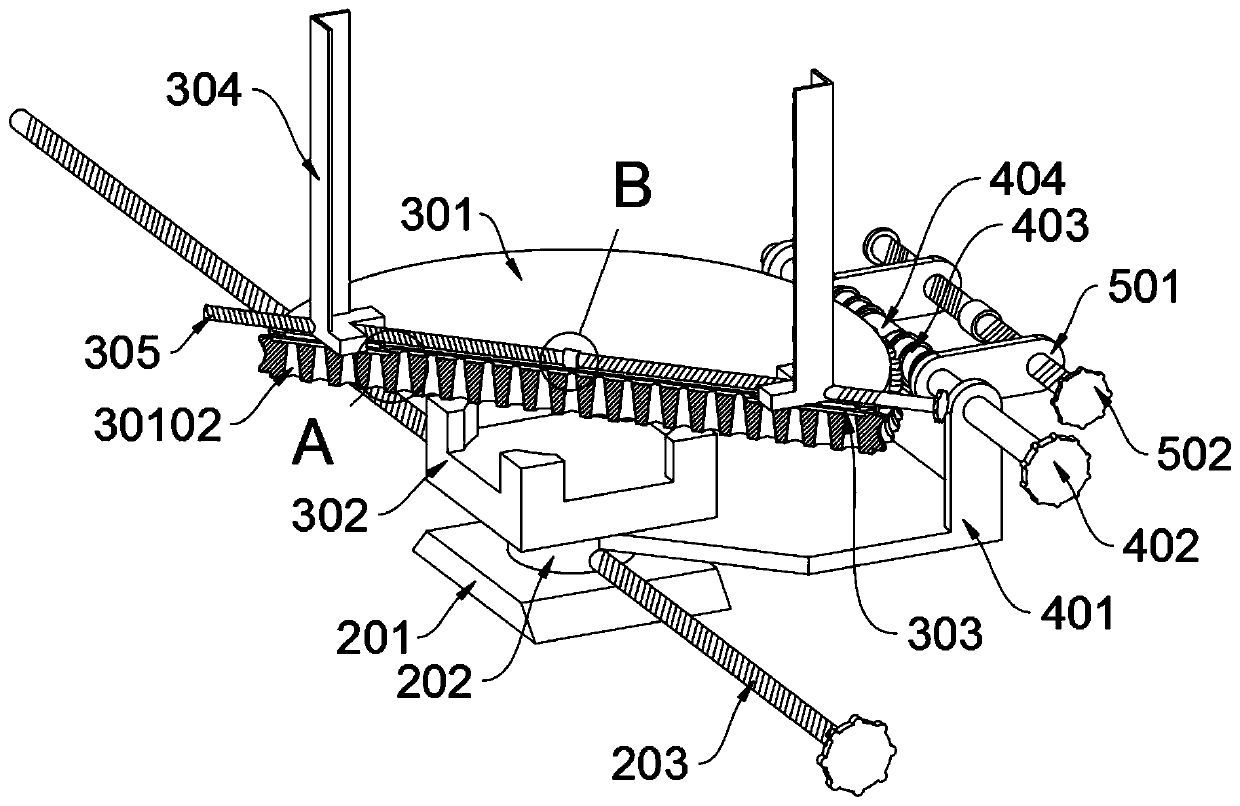

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The invention provides a placement type processing frame equipment for reprocessing high-strength structural ceramics, including a main body seat 1; an adjustment structure A2 is slidably connected to the main body seat 1, and a placement seat structure 3 is welded on the adjustment structure A2, and the adjustment structure A2 An adjustment structure B4 is also welded on the top; a locking structure 5 is slidingly connected on the adjustment structure B4; refer to as Figure 7 and Figure 8 , the locking structure 5 includes a locking piece 501 and a threaded rod C502. There are two locking pieces 501 in total, and the two locking pieces 501 are slidably connected to the rotating rod 402, and the two locking pieces 501 are respectively connected to the two threaded tubes 403 Contact; a threaded rod C502 is threadedly connected to the two locking pieces 501, and the thread directions at both ends of the threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com