A plastic woven bag production and processing method

A technology of plastic woven bag and processing method, which is applied in bag making operation, thin material processing, flexible container manufacturing and other directions, can solve the problem of unqualified plastic woven bag production, low accuracy and efficiency of manual cutting or stitching, etc. The problems of low production efficiency of plastic woven bags can reduce manual labor, improve production efficiency, and be easy to cut and disconnect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

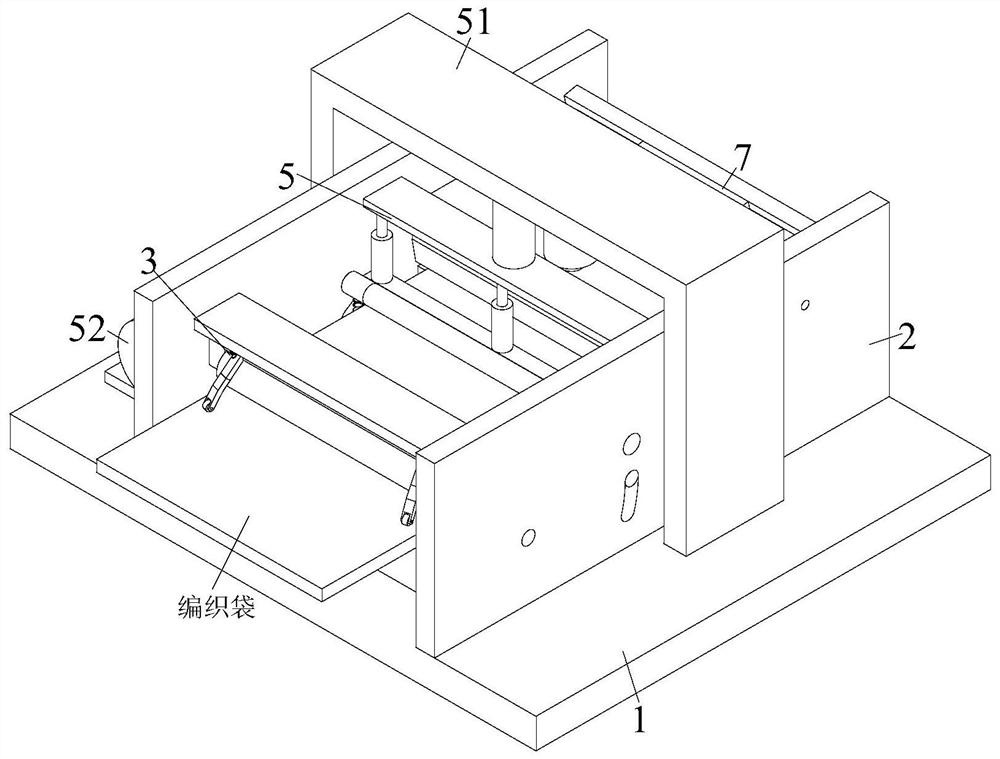

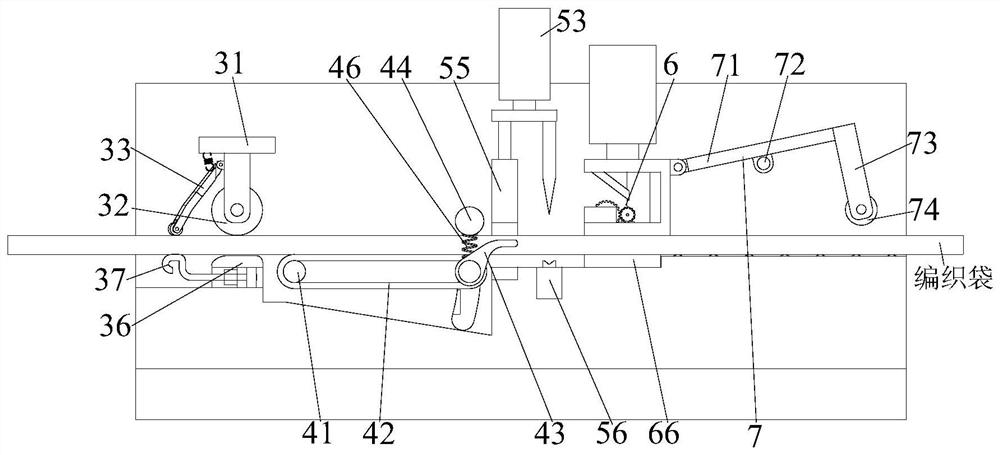

[0044] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 12 , to further elaborate the present invention.

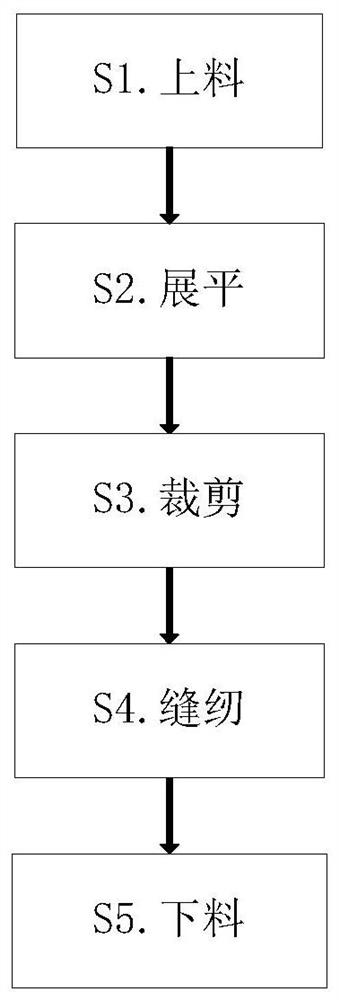

[0045] A kind of plastic woven bag manufacturing processing method, concrete manufacturing processing method is as follows:

[0046] S1. Feeding: Pass the woven bag manually between the connecting rod (33) and the mounting plate (36), so that the conveyor belt (42) pulls one end of the plastic woven bag for feeding;

[0047] S2. Flattening: After the feeding is completed, the plastic woven bag is pulled by the conveyor belt (42) to move, so that the flattening wheel (35) flattens the folds at the upper end of the plastic woven bag, and the lower end of the plastic woven bag is flattened by the support rod (37). The folds are flattened, and the flattened plastic woven bag is rolled and shaped by a flattening roller (32);

[0048] S3. Cutting: Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com