Natural gas well and well group

A natural gas and Christmas tree technology, applied in wellbore/well components, wellbore/well valve devices, and production fluids, etc., can solve problems such as energy waste, production stoppage, and bottom-hole fluid accumulation, and avoid large fluctuations , The effect of stabilizing the intake pressure and reducing the bottom hole fluid accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

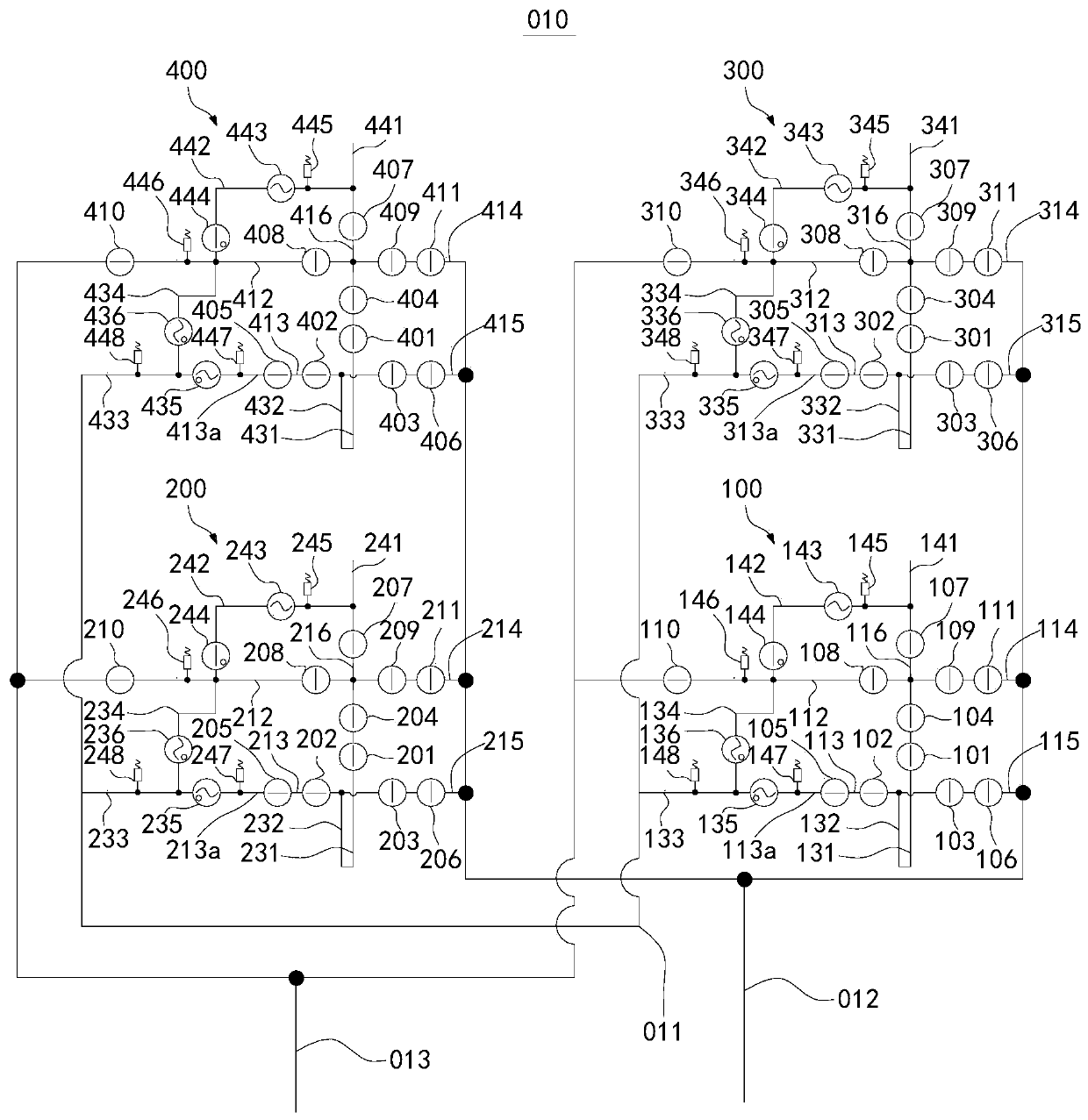

[0030] Please refer to figure 1 , the well group 010 provided in the embodiment of the present application includes four natural gas wells, namely the natural gas well 100 , the natural gas well 200 , the natural gas well 300 and the natural gas well 400 . The structures of the four natural gas wells are exactly the same. It should be noted that, in other embodiments, the number of natural gas wells is not limited to four. The well group 010 provided in this embodiment includes four natural gas wells is just an example. Preferably, the natural gas wells forming the well group 010 are located on the same platform.

[0031]In the embodiment of the present application, the natural gas well 100 includes a gas tree, a tubing 131 , a casing 132 , a first delivery pipeline 133 , a second delivery pipeline 134 , a first delivery regulation valve 135 and a second delivery regulation valve 136 . The gas tree includes No. 1 valve 101, No. 2 valve 102, No. 3 valve 103, No. 4 valve 104,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com