Density-sensitive adaptive flow control valve

A flow control valve, self-adaptive technology, applied in the direction of production fluid, sealing/isolation, wellbore/well valve device, etc., can solve problems such as gas breakthrough, inability to effectively control gas production, and affecting oilfield development benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

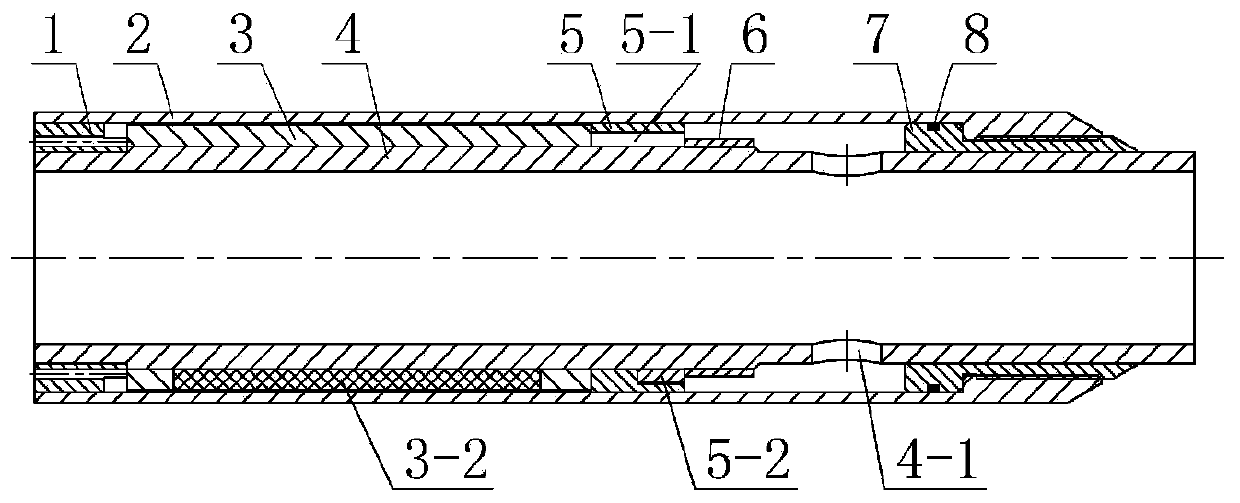

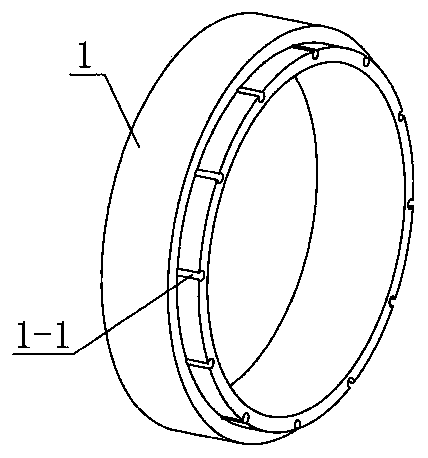

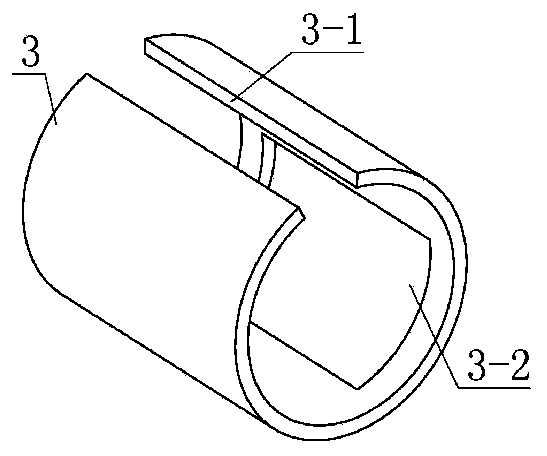

[0031] A density-sensitive adaptive flow control valve, comprising a base pipe 4, an overflow support ring 1, a floating plate 3, a positioning plate 5, a locking ring 6, an end ring 7 and an outer protective cover 2;

[0032] On the outer surface of the base pipe, a flow support ring, a floating plate, a positioning plate, a lock ring and an end ring are sequentially arranged from one side to the other side, and the inner diameter of the base pipe is 124.3 mm, and the outer diameter is 139.7 mm; figure 2 As shown, the flow support ring is used as the inlet of the fluid, and guide holes are evenly distributed on its circumference; at the same time, the locking ring is used to position the floating plate and the positioning plate at the upper limit in the radial direction; the floating plate and the positioning plate radially The outer surface of the base pipe is installed in a position-limited and rotatable manner; the end ring and the overflow support ring serve as a barrier ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com