A reusable igniter for a rocket engine

A rocket engine and igniter technology, which is applied to rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of repeated ignition, unstable combustion, etc., and achieve short ignition time, simple structure, and easy ignition. The effect of convenient location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

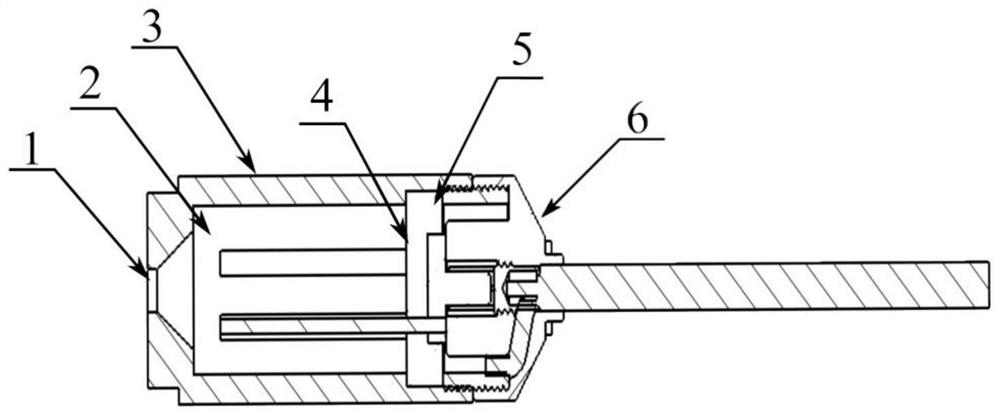

[0069] This embodiment provides a reusable igniter for rocket motors, such as figure 1 shown, including:

[0070] An external electrode 3 and an internal electrode 4, and a combustion chamber for accommodating an electronically controlled solid propellant is arranged between the external electrode 3 and the internal electrode 4; in this embodiment, the components of the electronically controlled solid propellant include lithium perchlorate , polyvinyl alcohol, metal aluminum powder, water and plasticizers, etc.

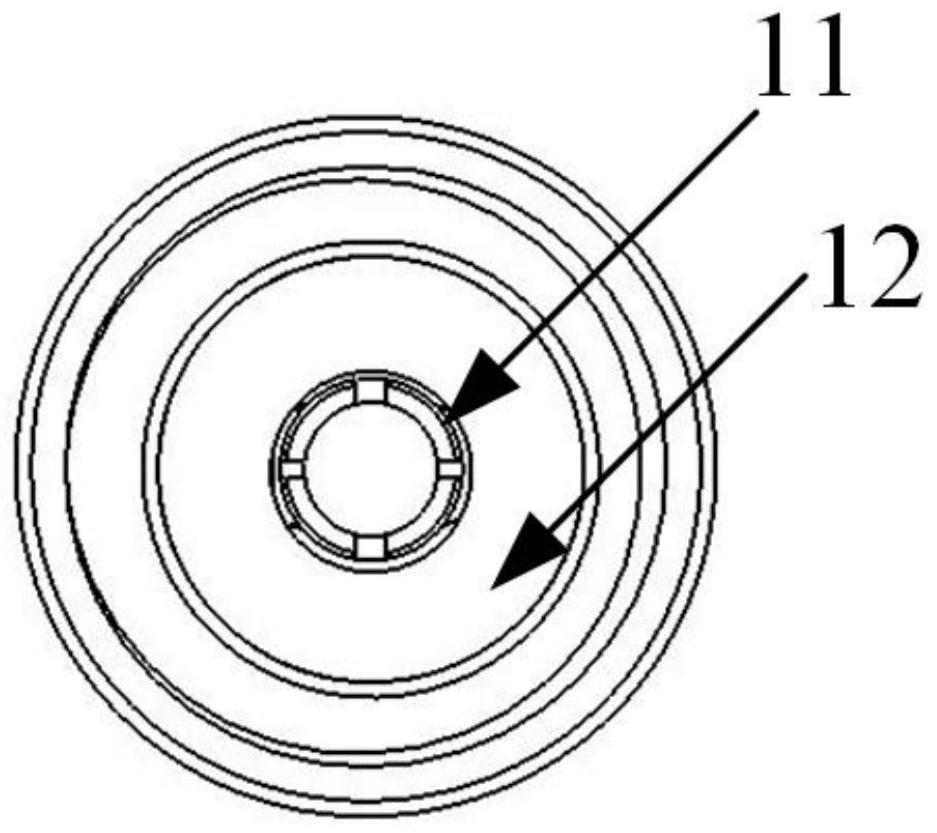

[0071] The outer electrode 3 surrounds the combustion chamber, and the inner electrode 4 is inserted in the electronically controlled solid propellant;

[0072] A conductive component, including an external electrode conductive component and an internal electrode conductive component electrically connected to the external electrode 3 and the internal electrode 4;

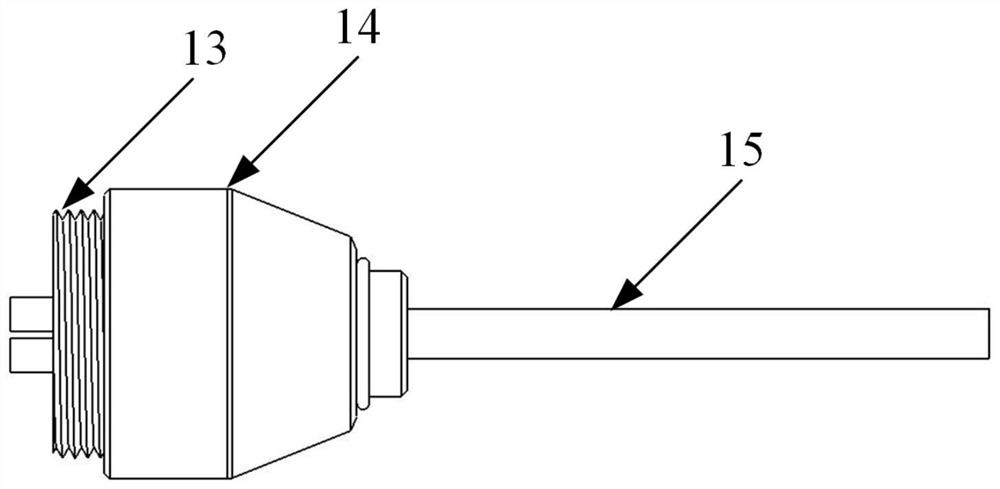

[0073] The conductive components such as figure 1 , Figure 2a with Figure 2b As shown, it include...

Embodiment 2

[0092] In this embodiment, the igniter 16 provided by Embodiment 1 is applied to liquid rocket motors, such as Figure 4 As shown, it includes: an igniter 16, a power supply unit 15, an insulating and heat-insulating protective cover 17, a tail base 18, and an external threaded interface 19 of the engine.

[0093] The tail base 18 is made of stainless steel, and is a sealed cylinder with an internal thread opening at one end and a round hole at the other end.

[0094] The housing and the engine of the igniter 16 are all cylindrical configurations; wherein, the external threaded interface 19 of stainless steel material is welded at the combustion chamber of the liquid rocket engine, and one end of the tail base 18 is provided with a joint that cooperates with the external threaded interface 19 of the engine. Internal thread structure. The casing of the igniter 16 is wrapped by an insulating and heat-insulating protective sheath 17 , and nested in the tail base 18 . The power ...

Embodiment 3

[0097] In this embodiment, the igniter 16 provided in Embodiment 1 is applied to a liquid ramjet rocket engine, such as Figure 5 As shown, it includes: two igniters 16, which are symmetrically installed on both sides of the liquid ramjet engine, a power supply unit 15, an insulating and heat-insulating protective sleeve 17, a fixing sleeve 20, and an inner threaded interface 21 in the engine cavity.

[0098] The fixing sleeve 20 is made of a stainless steel tube and is installed in the cavity of the liquid ramjet. One end of the fixing sleeve 20 is provided with an external thread that is compatible with the internal thread interface 21 of the cavity of the liquid ramjet. The central line of the nozzle 1 of the igniter coincides with a round hole with a diameter slightly larger than that of the nozzle 1; the other end is provided with an annular concave platform, and the concave platform is provided with a circular hole slightly larger than the diameter of the power supply uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com