Fully-automatic water pump state monitoring and fault diagnosis system

A fault diagnosis system and state monitoring device technology, applied in radial flow pumps, pumps, pump control, etc., can solve problems such as time-consuming and labor-intensive, waste of monitoring resources, and large error in results, so as to improve data processing efficiency and save monitoring Cost, the effect of improving monitoring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

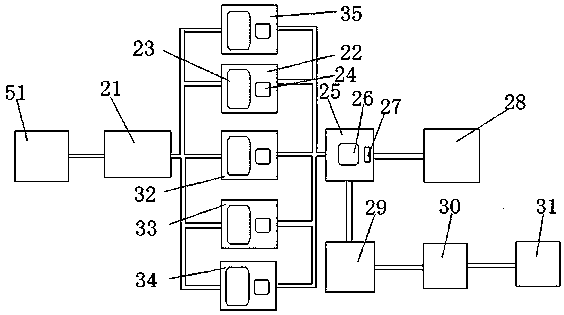

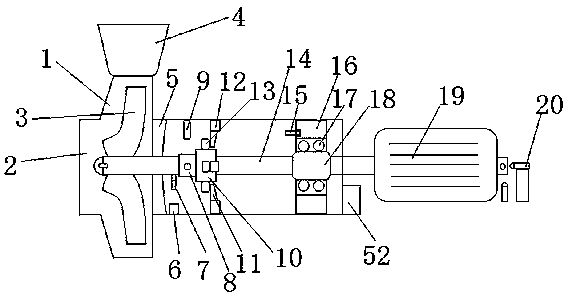

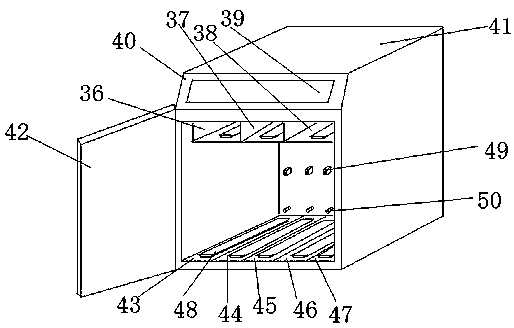

[0017] see Figure 1 to Figure 4 , the present invention relates to a fully automatic water pump state monitoring and fault diagnosis system, comprising a water pump state monitoring device 51, a network signal receiving module 21, a vibration monitoring module 22, a displacement monitoring module 32, a swing monitoring module 33, a temperature monitoring module 34, The speed monitoring module 35, the data output module 25 and the electrical cabinet 41; the water pump state monitoring device 51 is connected to the network signal receiving module 21, and the water pump state monitoring device 51 can transmit the monitored index parameters to the network signal receiving module 21 through the Internet; The network signal receiving module 21 is respectively connected to the vibration monitoring module 22, the displacement monitoring module 32, the swing monitoring module 33, the temperature monitoring module 34 and the rotational speed monitoring module 35, and distributes the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com